Murano Cross Cabriolet Z51 (2013 year). Manual - part 20

C1110 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

BRC-45

< DTC/CIRCUIT DIAGNOSIS >

[WITH VDC]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1110 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

DTC Logic

INFOID:0000000008462515

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn the ignition switch OFF

and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

DTC REPRODUCTION PROCEDURE

1.

Turn the ignition switch OFF to ON.

2.

Perform self-diagnosis for “ABS” with CONSULT.

Is DTC “C1110” detected?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000008462516

1.

REPLACE ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Replace ABS actuator and electric unit (control unit) when self-diagnostic result shows items other than those

applicable.

>> Replace ABS actuator and electric unit (control unit). Refer to

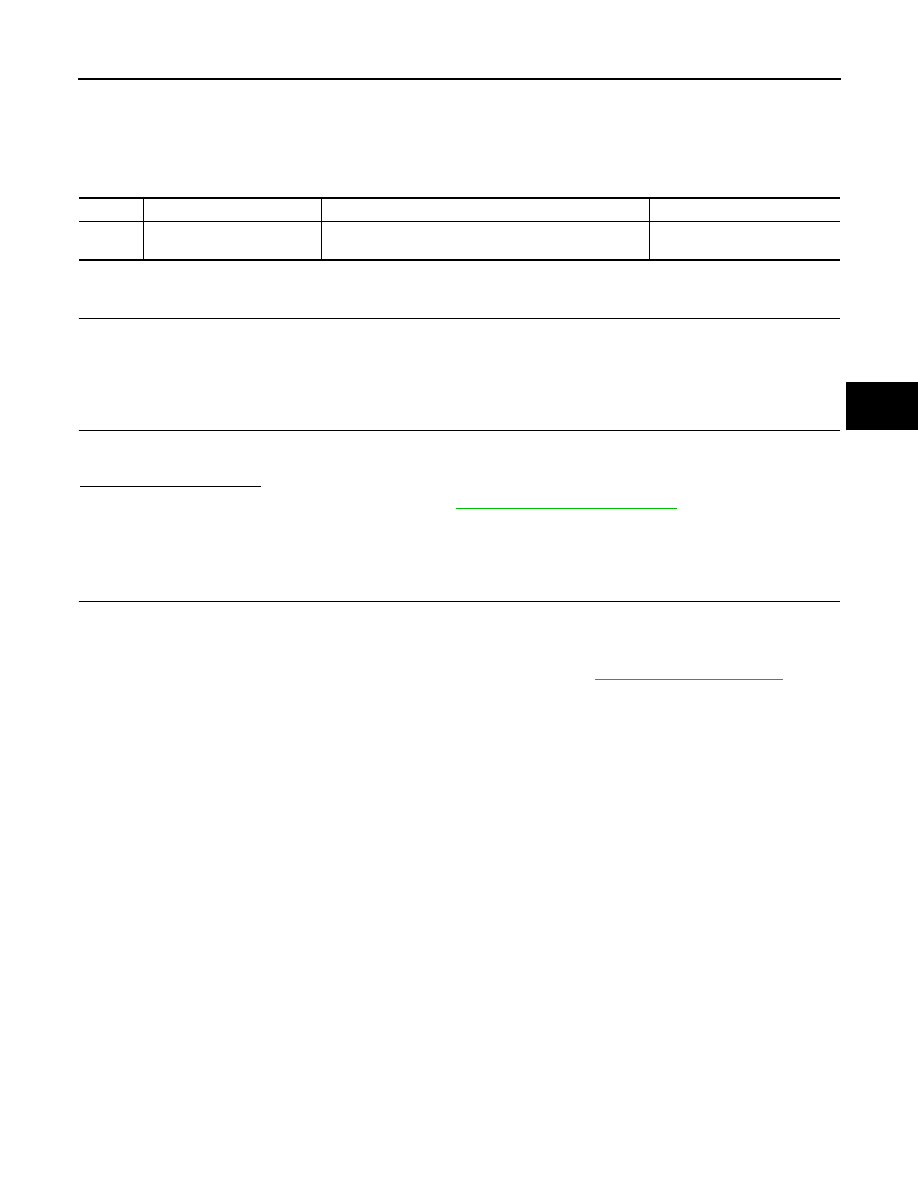

DTC

Display item

Malfunction detected condition

Possible cause

C1110

CONTROLLER FAILURE

When there is an internal malfunction in the ABS actuator

and electric unit (control unit).

ABS actuator and electric unit

(control unit)

Revision: 2012 October

2013 Murano CrossCabriolet