Nissan Murano Z51 (2013 year). Manual - part 21

RADIATOR

CO-17

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

Removal and Installation

INFOID:0000000008457848

REMOVAL

WARNING:

Never remove radiator cap when engine is hot. Serious burns could occur from high-pressure engine

coolant escaping from radiator. Wrap a thick cloth around the cap. Slowly turn it a quarter of a turn to

release built-up pressure. Carefully remove radiator cap by turning it all the way.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spill-

ing.

1.

Remove the following parts:

• Engine under cover.

• Radiator core support covers (RH and LH): Refer to

.

• Air duct (inlet): Refer to

.

• Front grille: Refer to

• Horn: Refer to

.

• Hood lock: Refer to

2.

Drain engine coolant from radiator. Refer to

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

3.

Disconnect reservoir tank hose from radiator pipe (upper).

4.

Disconnect CVT fluid cooler hoses from radiator.

• Install blind plug to avoid leakage of CVT fluid.

5.

Remove radiator cap adapter and each radiator hoses (upper) and radiator pipe (upper) assembly.

CAUTION:

Be careful not to allow engine coolant to contact drive belt.

6.

Disconnect radiator hose (lower) from radiator.

7.

Remove condenser. Refer to

.

CAUTION:

Be careful not to damage condenser core.

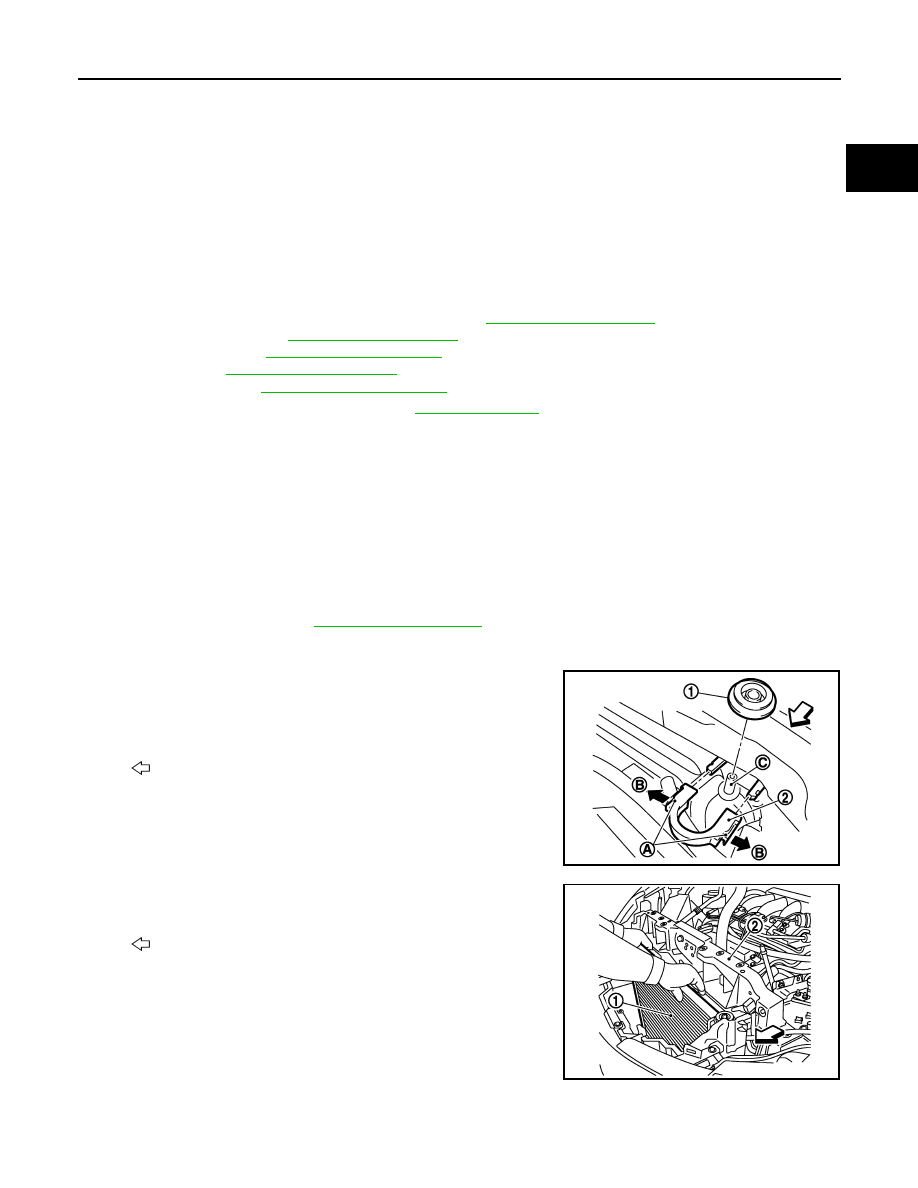

8.

Remove each radiator upper clips (2) by pulling the tabs (A) out-

side to release the lock (B) and then remove each mounting rub-

bers (upper) (1).

CAUTION:

Never pull the tabs outside excessively to prevent it from

damping.

9.

Lift up and remove radiator (1) from front of radiator core support

(2).

CAUTION:

Be careful not to damage or scratch on radiator core.

INSTALLATION

CAUTION:

Do not reuse O-rings.

C

: Mounting pin

: Vehicle front

JPBIA1689ZZ

: Vehicle front

JPBIA1699ZZ

Revision: 2012 September

2013 MURANO