Nissan Murano Z51 (2012 year). Manual - part 82

DIAGNOSIS SENSOR UNIT

SR-53

< REMOVAL AND INSTALLATION >

[FOR MEXICO]

C

D

E

F

G

I

J

K

L

M

A

B

SR

N

O

P

DIAGNOSIS SENSOR UNIT

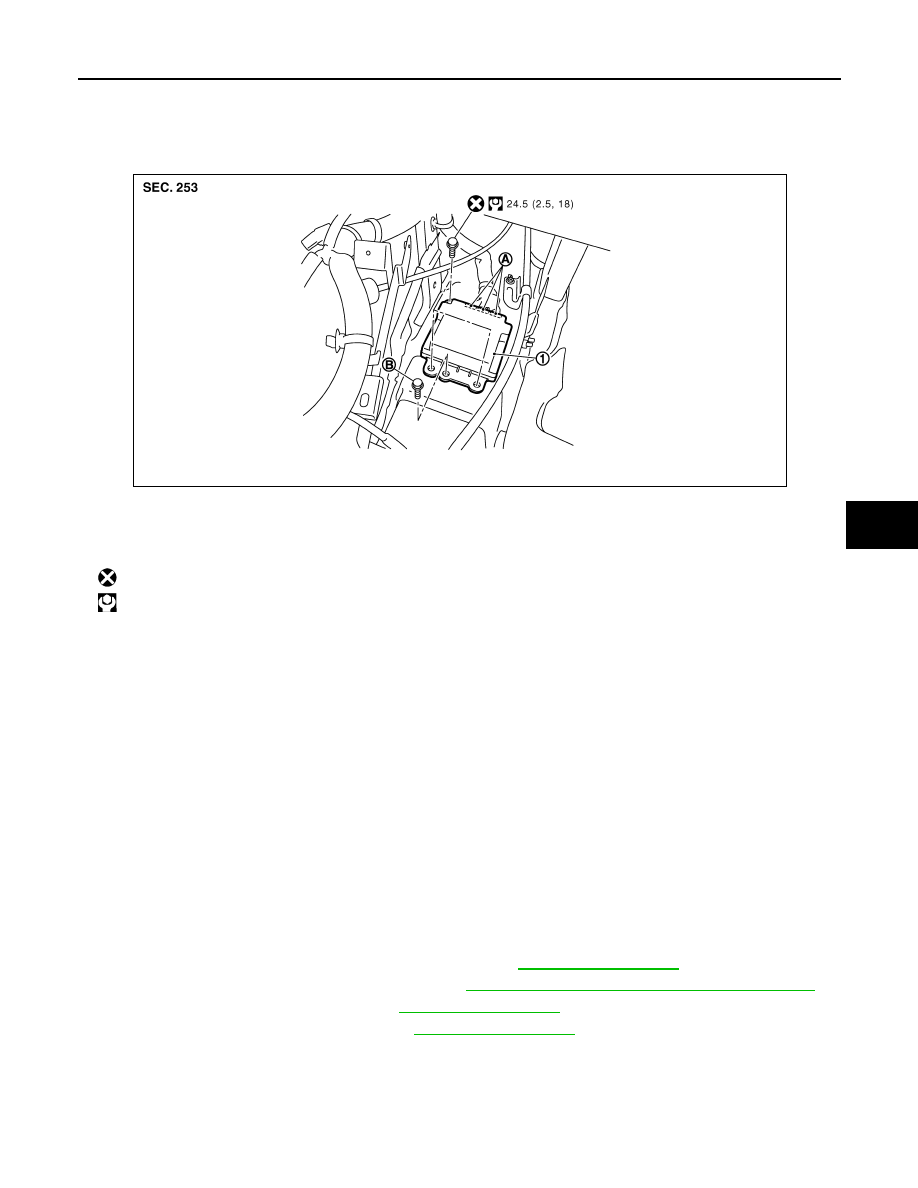

Exploded View

INFOID:0000000007539702

Removal and Installation

INFOID:0000000007539703

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative terminal and wait 3 minutes

or more.

• Before disconnecting the air bag sensor unit harness connector, be sure to disconnect the each har-

ness connector of the air bag module and pre-tensioner seat belt to prevent air bag deployment by

static electricity and pre-tensioner seat belt operation.

• Never use the air tools or electric tools for servicing.

• When replacing the air bag diagnosis sensor unit, always check with the parts department for the lat-

est parts information. Installing an incorrect air bag diagnosis sensor unit may or may not cause the

air bag warning lamp to illuminate and may cause incorrect deployment of the supplemental air bags

and seat belt pre-tensioners in a collision resulting in serious personal injury or death.

REMOVAL

1.

Always check the air bag diagnosis sensor unit ECU discriminated number (identification number) using

CONSULT.

2.

Disconnect the each connector of all air bag modules and pre-tensioner seat belts.

3.

Remove the instrument lower cover (LH and RH). Refer to

.

4.

Remove the rear foot duct 1 (LH and RH). Refer to

VTL-125, "REAR FOOT DUCT 1 : Exploded View"

.

5.

Remove the instrument stay LH. Refer to

6.

Remove the front console bracket. Refer to

7.

Disconnect the diagnosis sensor unit harness connectors.

8.

Remove the fixing bolts, ground bolt, and then remove the diagnosis sensor unit.

CAUTION:

1.

Diagnosis sensor unit

A.

Diagnosis sensor unit harness connector

B.

Ground bolt

: Do not reuse

: N·m (kg-m, ft-lb)

JMHIA0517GB

Revision: 2013 February

2012 MURANO