Nissan Murano Z51 (2011 year). Manual - part 55

POWER STEERING OIL PUMP

ST-61

< REMOVAL AND INSTALLATION >

[WITH HEATED STEERING WHEEL]

C

D

E

F

H

I

J

K

L

M

A

B

ST

N

O

P

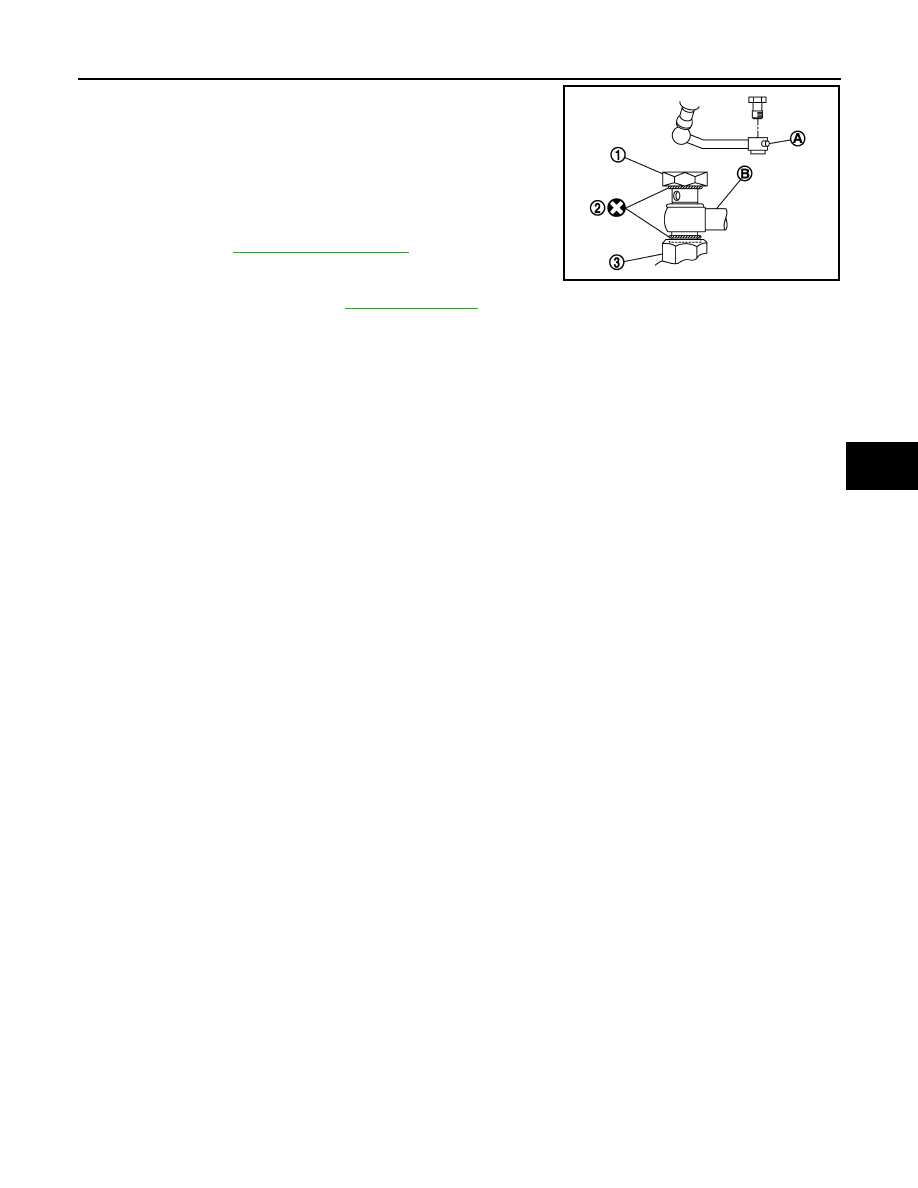

6.

When installing eye bolt (1) and copper washers (2) to oil pump

(3), refer to the figure.

CAUTION:

• Never reuse copper washer.

• Apply power steering fluid or equivalent to around copper

washer, then install eye bolt.

• Install eye bolt with eye joint (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specified torque after tightening by

hand. Refer to

• Securely insert harness connector to pressure sensor.

7.

Check fluid level, fluid leakage and air bleeding hydraulic sys-

tem after the installation. Refer to

.

BEFORE DISASSEMBLY

Disassemble oil pump only when the following malfunctions occur.

• If oil leakage is found on oil pump.

• Oil pump pulley is damaged or deformed.

• Performance of oil pump is low.

AFTER DISASSEMBLY

Body Assembly and Rear Cover Inspection

• Check body assembly and rear cover for internal damage. Replace rear cover if it is damaged. Replace oil

pump assembly if body assembly is damaged.

Cartridge Assembly Inspection

• Check cam ring, rotor and vane for damage. Replace cartridge assembly if necessary.

Side Plate Inspection

• Check side plate for damage. Replace side plate if necessary.

Flow Control Valve Inspection

• Check flow control valve and spring for damage. Replace if necessary.

SGIA1379E

Revision: 2011 November

2011 MURANO