Nissan Murano Z50 (2007 year). Manual - part 82

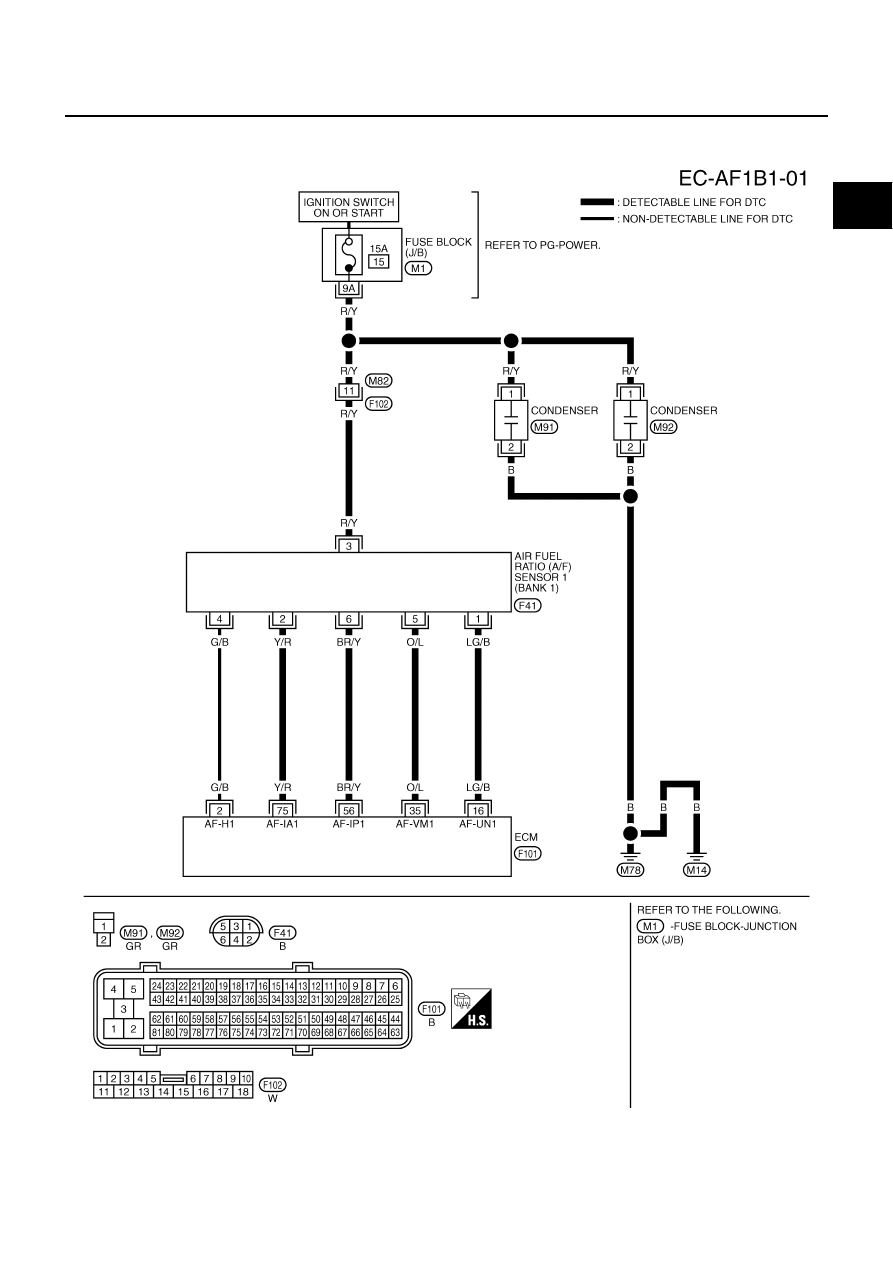

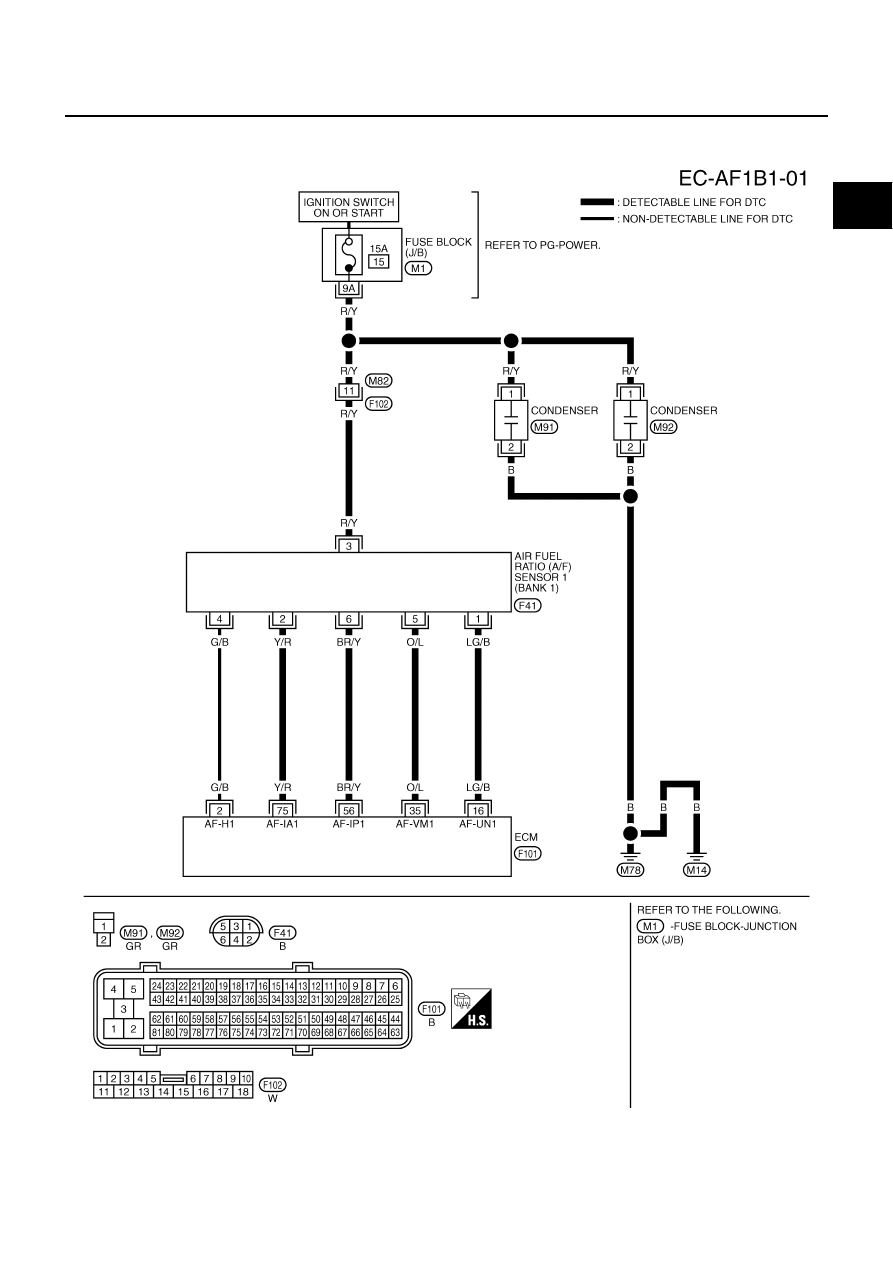

DTC P0133, P0153 A/F SENSOR 1

EC-261

C

D

E

F

G

H

I

J

K

L

M

A

EC

Revision: 2006 July

2007 Murano

Wiring Diagram

NBS003AG

BANK 1

TBWM1631E

|

|

|

DTC P0133, P0153 A/F SENSOR 1 EC-261 C D E F G H I J K L M A EC Revision: 2006 July 2007 Murano Wiring Diagram NBS003AG BANK 1 TBWM1631E |