Nissan Murano Z50 (2005 year). Manual - part 209

STARTING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

M

A

B

SC

Revision: 2005 August

2005 Murano

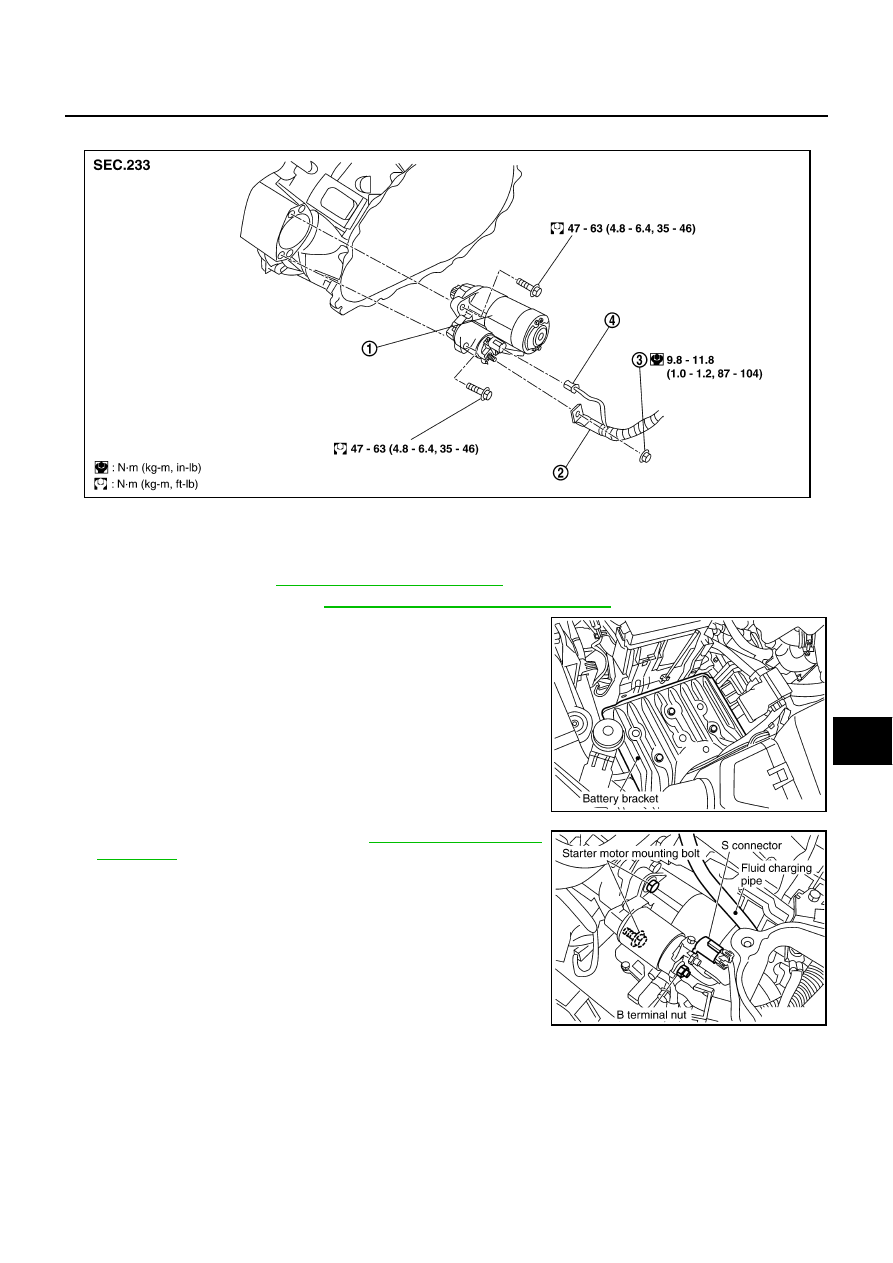

Removal and Installation

AKS004F2

REMOVAL

1.

Remove battery. Refer to

SC-8, "Removal and Installation"

.

2.

Remove air duct (inlet). Refer to

EM-16, "AIR CLEANER AND AIR DUCT"

3.

Remove battery bracket, using power tools.

4.

Remove fluid charging pipe. Refer to

.

5.

Disconnect “S” connector.

6.

Remove “B” terminal nut.

7.

Remove starter motor mounting bolts, using power tools.

8.

Remove starter motor upward from the vehicle.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1.

Starter motor

2.

B terminal harness

3.

B terminal nut

4.

S connector

PKIA2424E

PKIA2851E

PKIA2425E