Nissan Murano Z51 (2008 year). Manual - part 299

PWO-2

< COMPONENT DIAGNOSIS >

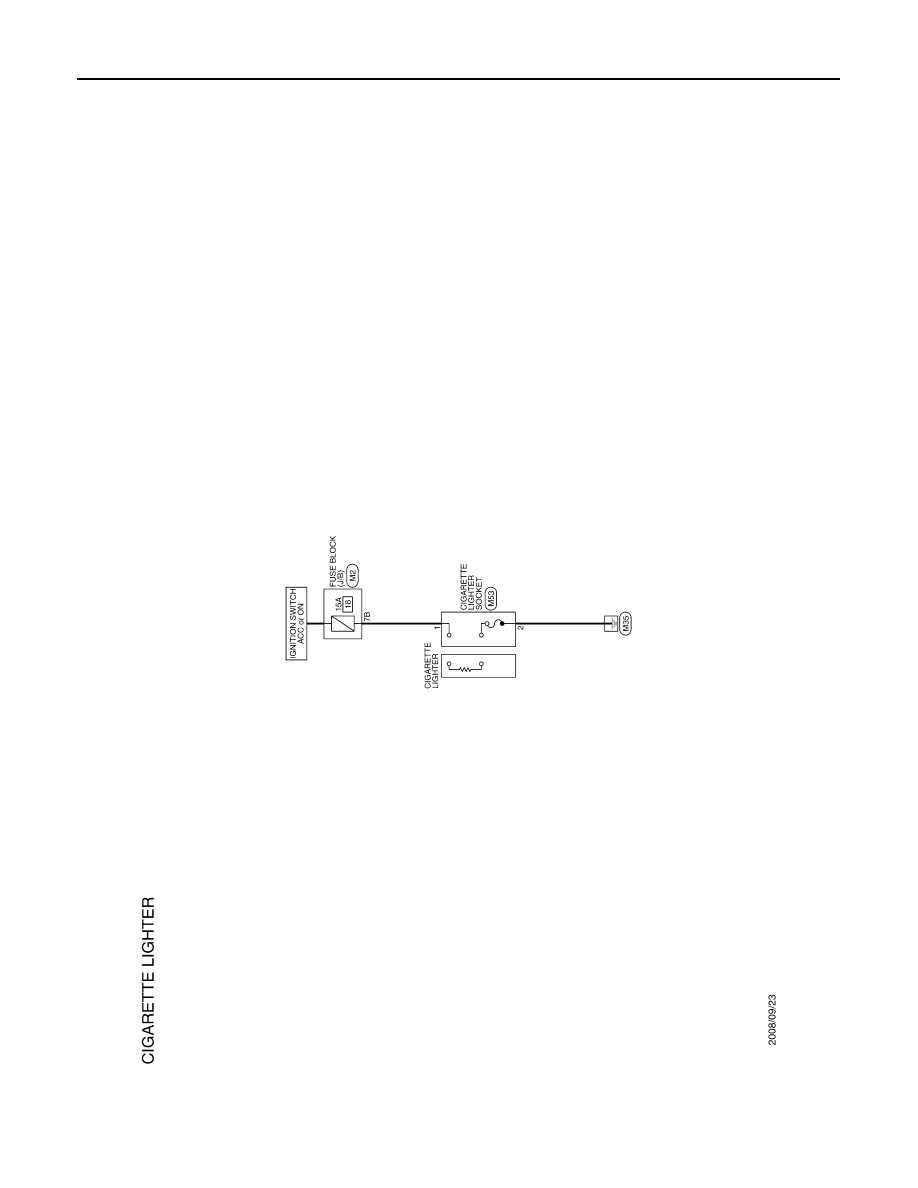

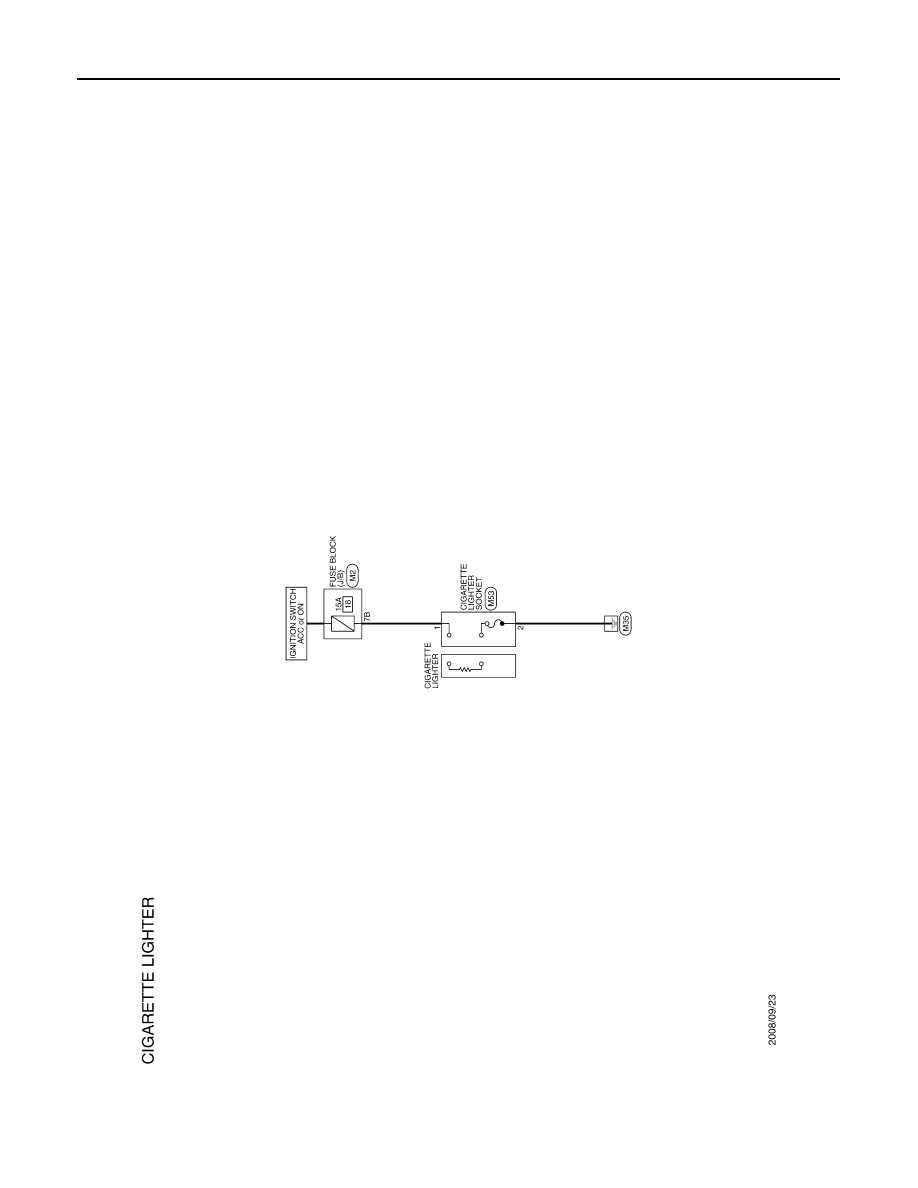

CIGARETTE LIGHTER

COMPONENT DIAGNOSIS

CIGARETTE LIGHTER

Wiring Diagram - CIGARETTE LIGHTER -

INFOID:0000000003372920

JCMWM3147GB

Revision: 2008 October

2009 Murano

|

|

|

PWO-2 < COMPONENT DIAGNOSIS > CIGARETTE LIGHTER COMPONENT DIAGNOSIS CIGARETTE LIGHTER Wiring Diagram - CIGARETTE LIGHTER - INFOID:0000000003372920 JCMWM3147GB Revision: 2008 October 2009 Murano |