Nissan Murano Z51 (2008 year). Manual - part 179

CYLINDER BLOCK

EM-129

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

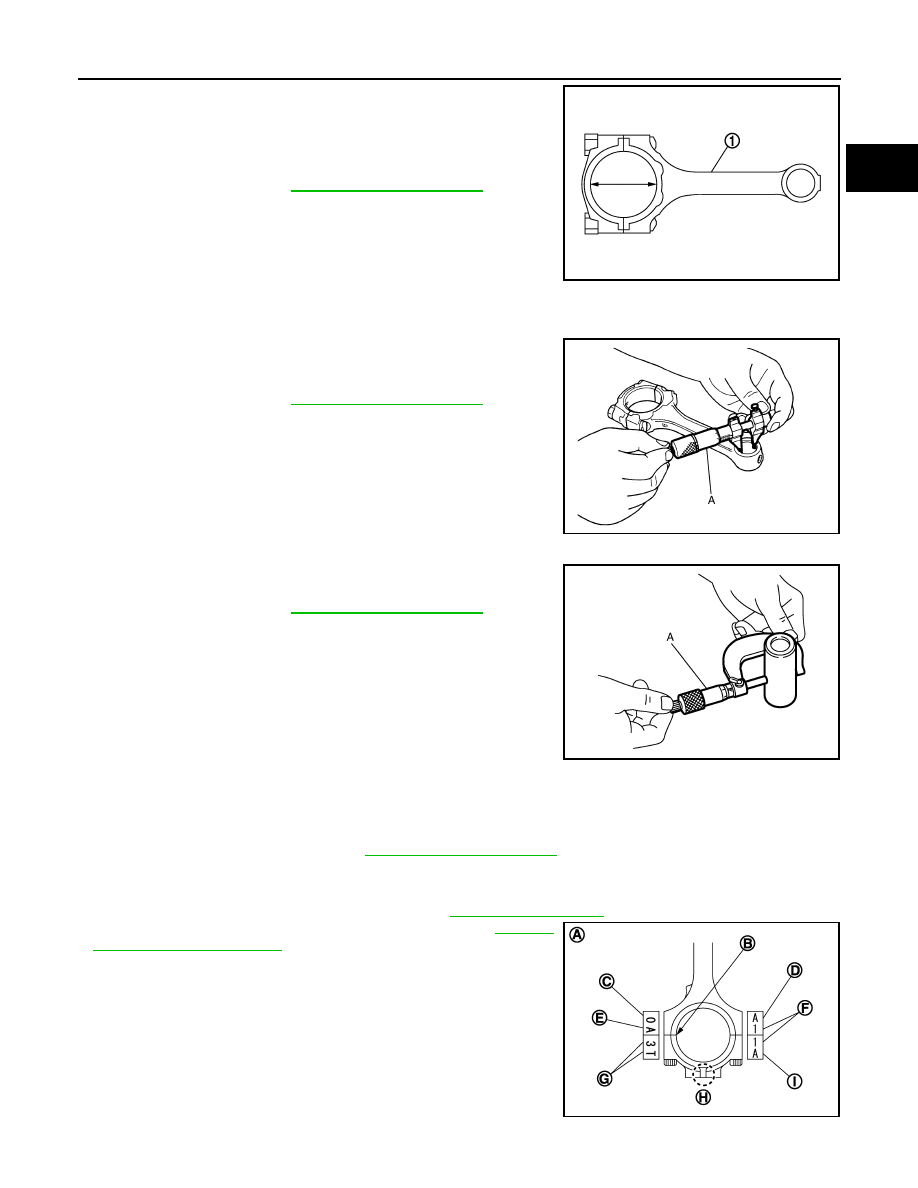

• Measure the inner diameter of connecting rod big end with an

inside micrometer.

• If out of the standard, replace connecting rod assembly.

CONNECTING ROD BUSHING OIL CLEARANCE

Connecting Rod Bushing Inner Diameter

Measure the inner diameter of connecting rod bushing with an inside

micrometer (A).

Piston Pin Outer Diameter

Measure the outer diameter of piston pin with a micrometer (A).

Connecting Rod Bushing Oil Clearance

(Connecting rod bushing oil clearance) = (Connecting rod bushing inner diameter) – (Piston pin outer diame-

ter)

• If the calculated value exceeds the limit, replace connecting rod assembly and/or piston and piston pin

assembly.

• If replacing piston and piston pin assembly, refer to

• If replacing connecting rod assembly, refer to

to select the connecting rod bearing.

1

: Connecting rod

Standard

: Refer to

JPBIA0222ZZ

Standard

: Refer to

JPBIA0223ZZ

Standard

: Refer to

JPBIA0218ZZ

Standard and limit

: Refer to

A

: Sample codes

B

: Bearing stopper groove

C

: Small-end diameter grade

D

: Standard stamp

E

: Weight grade

F

: Cylinder No.

G

: Management code

JPBIA0208ZZ

Revision: 2008 October

2009 Murano