Nissan Murano Z51 (2008 year). Manual - part 159

EC-360

< COMPONENT DIAGNOSIS >

[VQ35DE]

P1225 TP SENSOR

3.

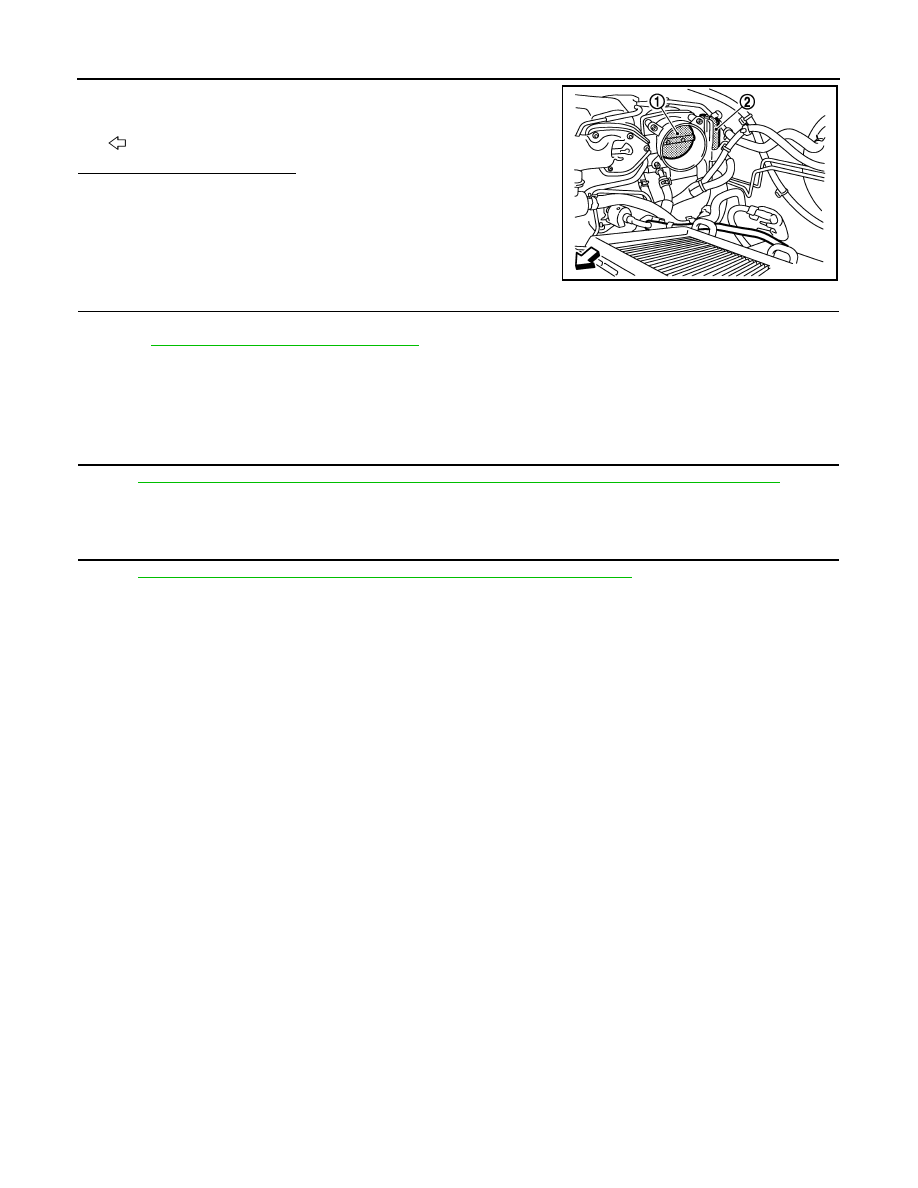

Check if foreign matter is caught between the throttle valve (1)

and the housing.

-

Electric throttle control actuator (2)

-

: Vehicle front

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace electric throttle control actuator.

2.

Go to

EC-360, "Special Repair Requirement"

.

>> INSPECTION END

Special Repair Requirement

INFOID:0000000003591588

1.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-17, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 2.

2.

PERFORM IDLE AIR VOLUME LEARNING

EC-17, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> END

JMBIA1132ZZ

Revision: 2008 October

2009 Murano