содержание .. 586 587 588 589 ..

Nissan Murano. Manual - part 588

EC-462

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

3.

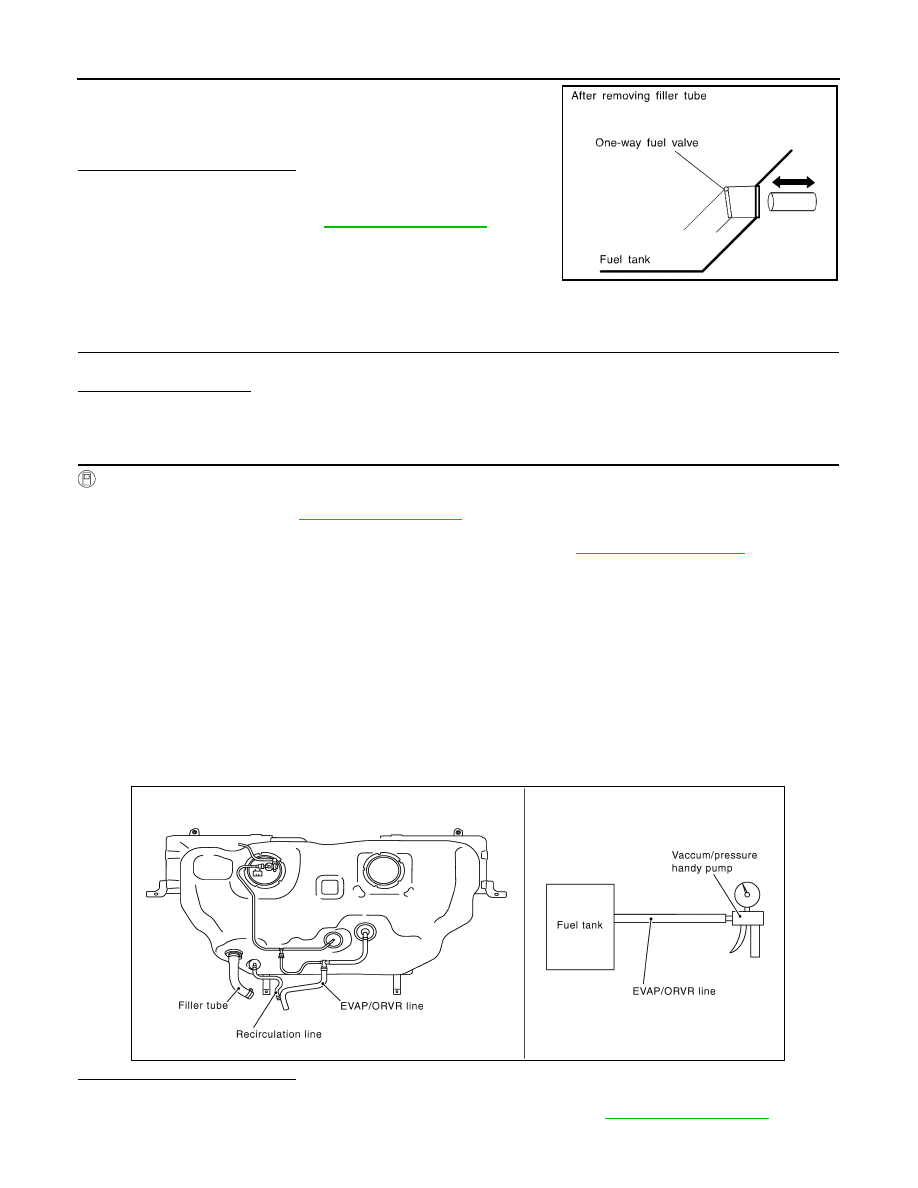

Check one-way fuel valve for operation as per the following.

When a stick is inserted, the valve should open, when removing

stick it should close.

Do not drop any material into the tank.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace fuel filler tube or replace one-way fuel valve

with fuel tank. Refer to

Component Inspection

INFOID:0000000009720231

1.

INSPECTION START

Will CONSULT be used?

Will CONSULT be used?

YES

>> GO TO 2.

NO

>> GO TO 3.

2.

CHECK REFUELING EVAP VAPOR CUT VALVE

With CONSULT

1.

Turn ignition switch OFF.

2.

Remove fuel tank. Refer to

.

3.

Drain fuel from the tank as per the following:

-

Remove fuel feed hose located on the fuel gauge retainer. Refer to

.

-

Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other

side to a fuel container.

-

Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode with CONSULT.

4.

Check refueling EVAP vapor cut valve for being stuck to close as per the following.

Blow air into the refueling EVAP vapor cut valve (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

5.

Check refueling EVAP vapor cut valve for being stuck to open as per the following.

-

Connect vacuum pump to hose end.

-

Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

-

Turn fuel tank upside down.

-

Apply vacuum pressure to hose end [

−

13.3 kPa (

−

0.136 kg/cm

3

,

−

1.93 psi)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace refueling EVAP vapor cut valve with fuel tank. Refer to

SEF665U

JMBIA1126GB