содержание .. 956 957 958 959 ..

Nissan X-Trail 32. Manual - part 958

ACCELERATOR PEDAL

EC-961

< BASIC INSPECTION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

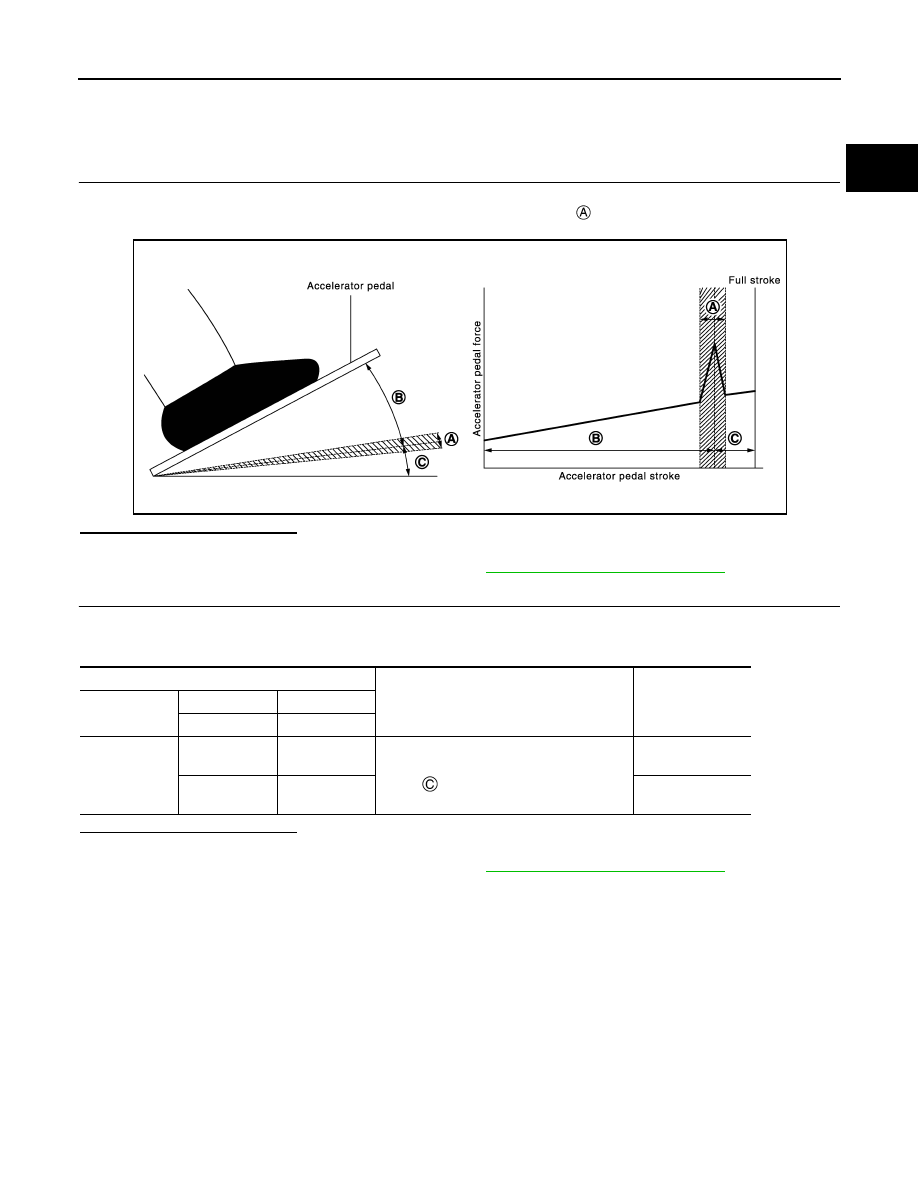

ACCELERATOR PEDAL

Work Procedure

INFOID:0000000010935621

1.

PERFORM ACCELERATOR PEDAL FORCE-I

1.

Turn ignition switch OFF.

2.

Depress the accelerator pedal and check if there is a specific point

in the pedal stroke where the pedal

force increase as shown in the figure.

Is the inspection result normal?

YES-1 >> GO TO 2.

NO

>> Replace accelerator pedal assembly. Refer to

ACC-4, "Removal and Installation"

2.

PERFORM ACCELERATOR PEDAL FORCE-II

1.

Turn ignition switch ON.

2.

Check the voltage between ECM harness connector and ground under the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace accelerator pedal assembly. Refer to

ACC-4, "Removal and Installation"

JMBIA1519GB

ECM

Condition

Voltage

Connector

+

–

Terminal

Terminal

E79

2

(APP sensor 1)

3

Depressing range of the accelerator pedal:

Within

as indicated in the figure

More than 4.35 V

11

(APP sensor 2)

12

More than 2.17 V