содержание .. 924 925 926 927 ..

Nissan X-Trail 32. Manual - part 926

SYSTEM

EC-833

< SYSTEM DESCRIPTION >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

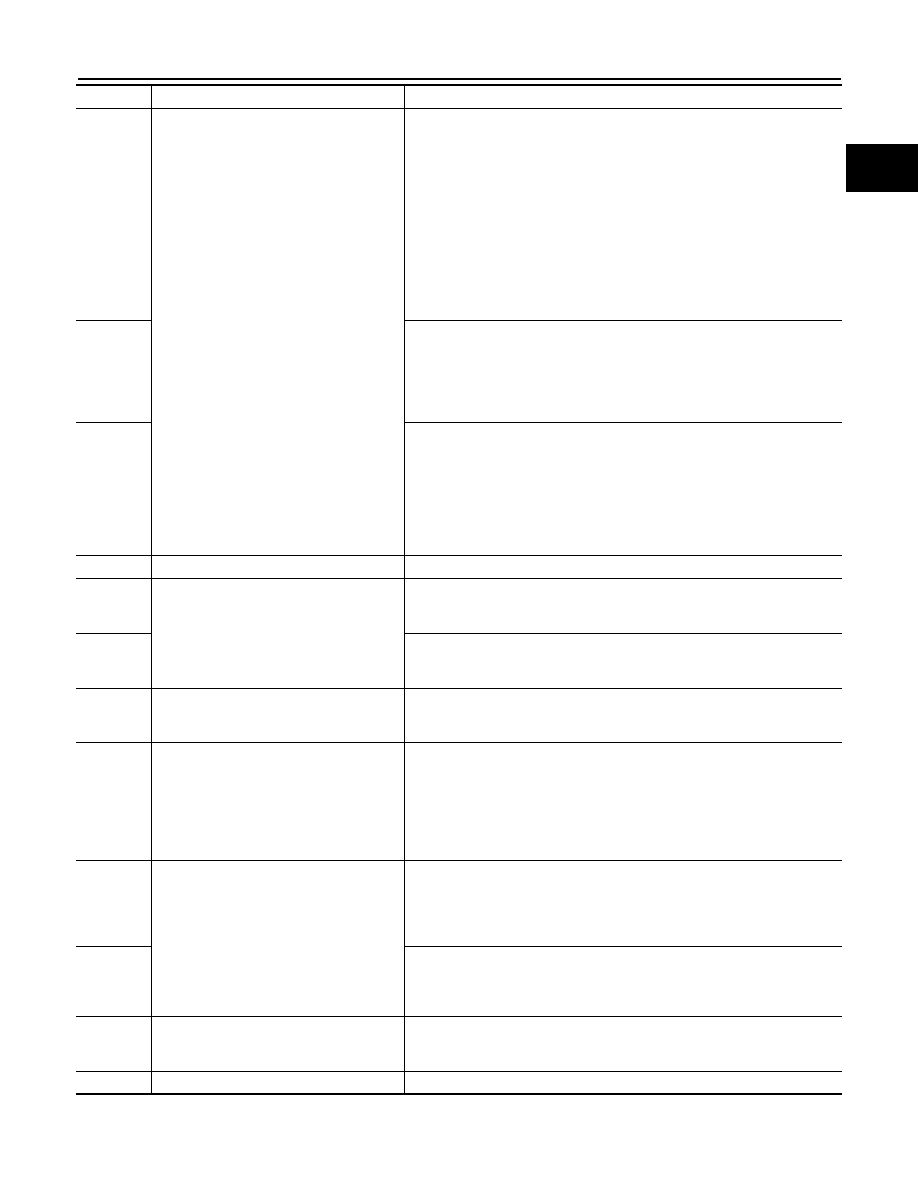

P0641

Sensor power supply

• EGR valve is closed position

• Throttle control motor is opened

• The pressure downstream turbo exists then the limit: Otherwise cut regu-

lation turbo

• Limited upstream turbine pressure regulation if the sensor is present: Oth-

erwise, the boost pressure regulation is cut

• Torque limitation

• Airflow regulation cut off

• CSF regeneration forbidden

• CCSL deactivation with dashboard message

• Freeshift inhibited

• Increased idle speed

• After sales routines forbidden

P0651

• Air conditioner deactivation

• Torque limitation

• CCSL deactivation with dashboard message

• Freeshift inhibited

• After sales routines forbidden

• FAN 2 activation

P0697

• EGR valve is closed position

• Throttle control motor is opened

• Rail pressure limitation

• CSF regeneration forbidden

• After sales routines forbidden

• CCSL deactivation with dashboard message

• Freeshift inhibited

• ESP deactivated and AGB in limp home mode

P0833

DPF pressure sensor

CC/SL not available

P1010

P1012

P1013

Intake manifold runner control valve

Stop intake manifold runner control valve control (Fully open position)

P1011

• Stop intake manifold runner control valve control (Fully open position)

• CCSL deactivation

• Freeshift inhibition

P1453

DPF pressure sensor

• EGR valve is closed position

• Throttle control motor is opened

• Prohibit DPF regeneration

P1480

P1481

P1482

P1483

Exhaust electric throttle control actuator

• EGR valve is closed position

• Throttle control motor is opened

• Airflow regulation cut off

• CSF regeneration forbidden

• Compression test routine forbidden

• CCSL deactivation with dashboard message

• Freeshift inhibited

P1484

P1485

P1486

P1487

P1488

Low pressure EGR volume control valve

• EGR valve is closed position

• Throttle control motor is opened

• CSF regenerations forbidden

• CCSL deactivation with dashboard message

• Freeshift inhibited

P1489

• EGR valve is closed position

• Throttle control motor is opened

• Temperature sensor after EGR cooler overheat signal diagnostic set of

data to call the failure manag.

P1544

Exhaust gas temperature sensor 2 circuit

• EGR valve is closed position

• Throttle control motor is opened

• Prohibit DPF regeneration

P1620

ECM

Stop closed-loop control

DTC No.

Detected items

Engine operating condition in fail-safe mode