содержание .. 911 912 913 914 ..

Nissan X-Trail 32. Manual - part 913

FUEL INJECTOR

EC-781

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

3.

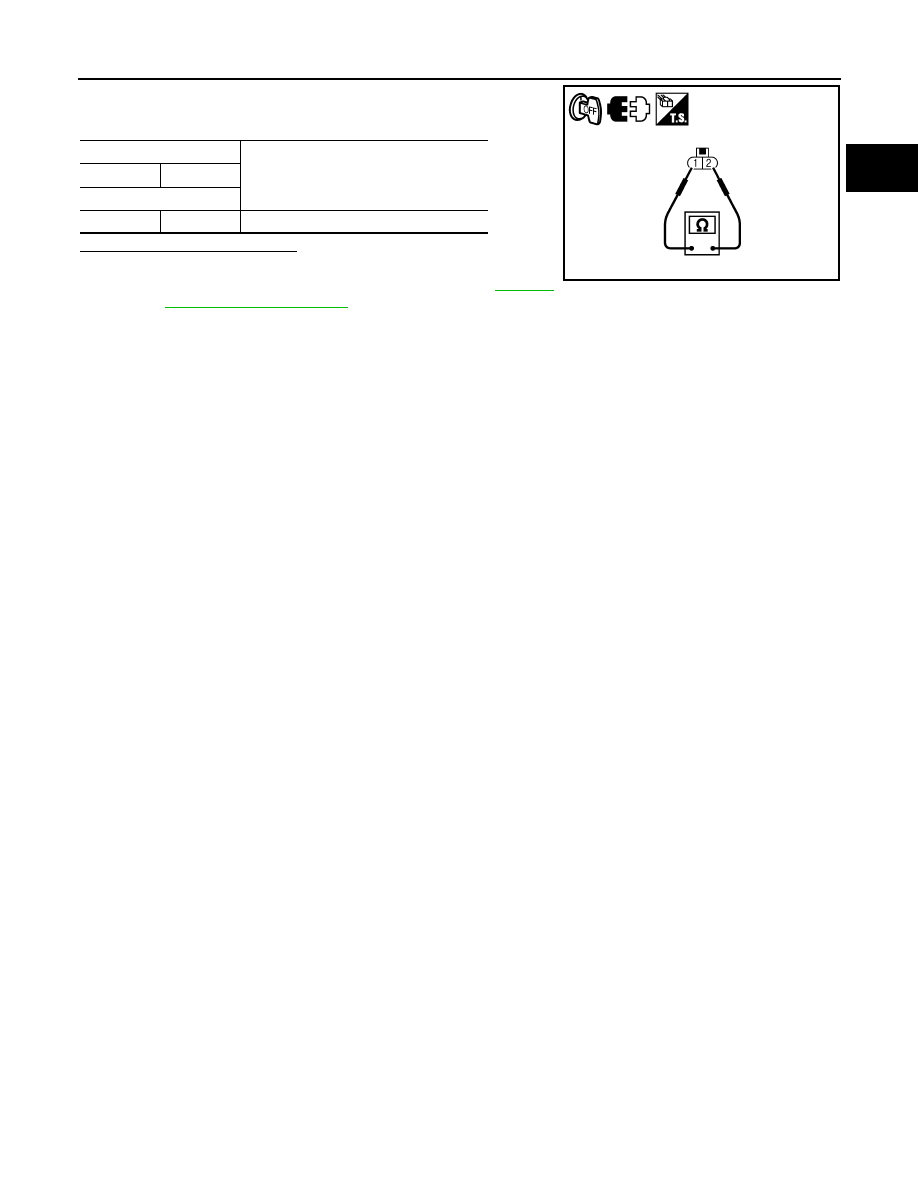

Check resistance between fuel injector terminals as per the fol-

lowing.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning fuel injector. Refer to

.

Fuel injector

Resistance

+

-

Terminal

1

2

11.1 - 14.5

Ω

[at 10 - 60

°

C (50 - 140

°

F)]

PBIA9579J