содержание .. 888 889 890 891 ..

Nissan X-Trail 32. Manual - part 890

P0444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

EC-689

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Component Inspection

INFOID:0000000010986376

1.

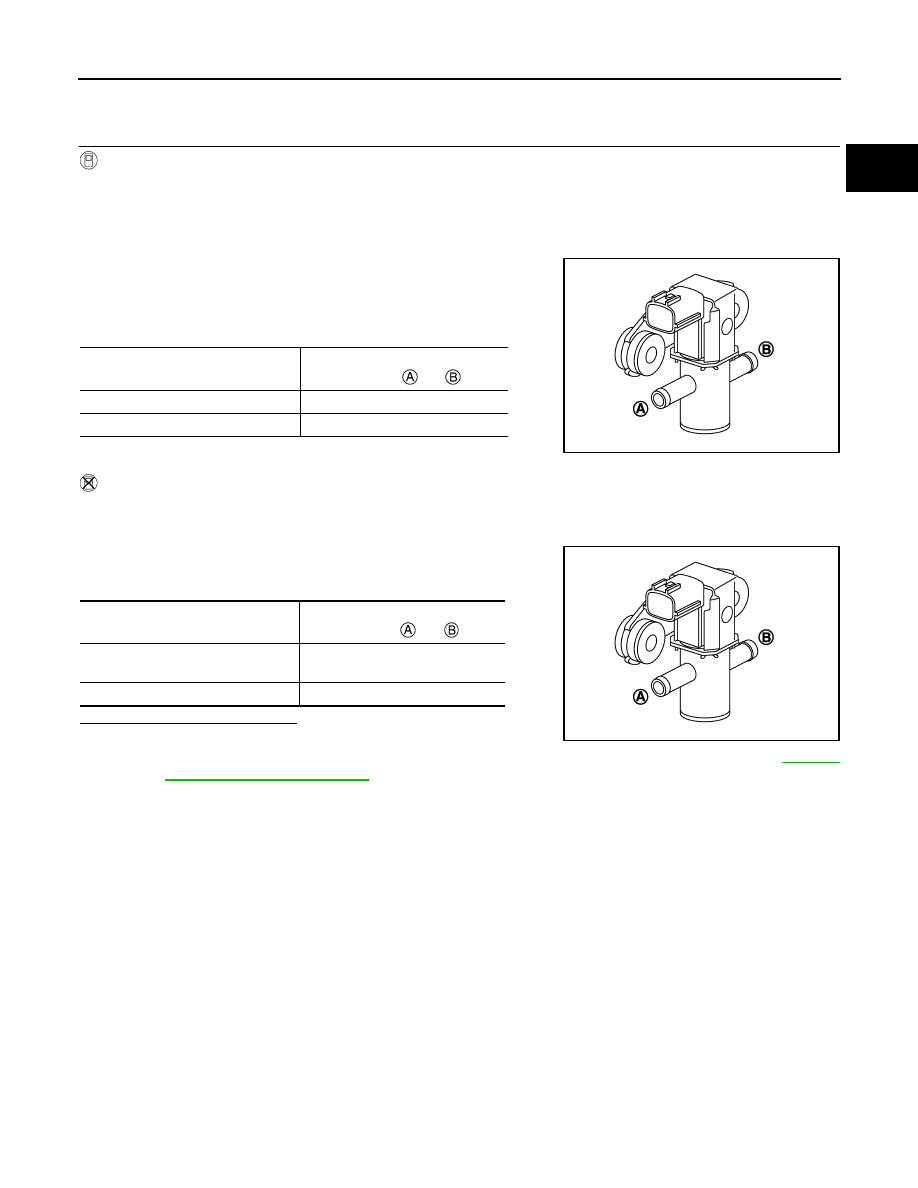

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT

1.

Turn ignition switch OFF.

2.

Reconnect all harness connectors disconnected.

3.

Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

4.

Start engine.

5.

Select “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

6.

Touch “Qd” and “Qu” on CONSULT screen to adjust “PURG

VOL C/V” opening and check air passage continuity of EVAP

canister purge volume control solenoid valve as per the follow-

ing conditions.

Without CONSULT

1.

Turn ignition switch OFF.

2.

Disconnect EVAP canister purge volume control solenoid valve harness connector.

3.

Disconnect EVAP purge hoses connected to EVAP canister purge volume control solenoid valve.

4.

Check air passage continuity of EVAP canister purge volume

control solenoid valve as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace EVAP canister purge volume control solenoid valve. Refer to

.

Condition

(PURG VOL C/V value)

Air passage continuity

between

and

100%

Existed

0%

Not existed

JMBIA0068ZZ

Condition

Air passage continuity

between

and

12 V direct current supply between

terminals 1 and 2

Existed

No supply

Not existed

JMBIA0068ZZ