содержание .. 815 816 817 818 ..

Nissan X-Trail 32. Manual - part 817

HIGH PRESSURE FUEL PUMP

EC-397

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

10.

CHECK HIGH PRESSURE FUEL PUMP INSTALLATION

1.

Turn ignition switch OFF.

2.

Check high pressure fuel pump for improper attachment or looseness.

Is the inspection result normal?

YES

>> GO TO 11.

NO

>> Repair or replace malfunctioning part.

11.

CHECK CAMSHAFT

1.

Remove camshaft. Refer to

EM-81, "Removal and Installation"

2.

Check camshaft. Refer to

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-44, "Intermittent Incident"

.

NO

>> Replace camshaft. Refer to

EM-81, "Removal and Installation"

.

Component Inspection (High Pressure Fuel Pump)

INFOID:0000000010775287

1.

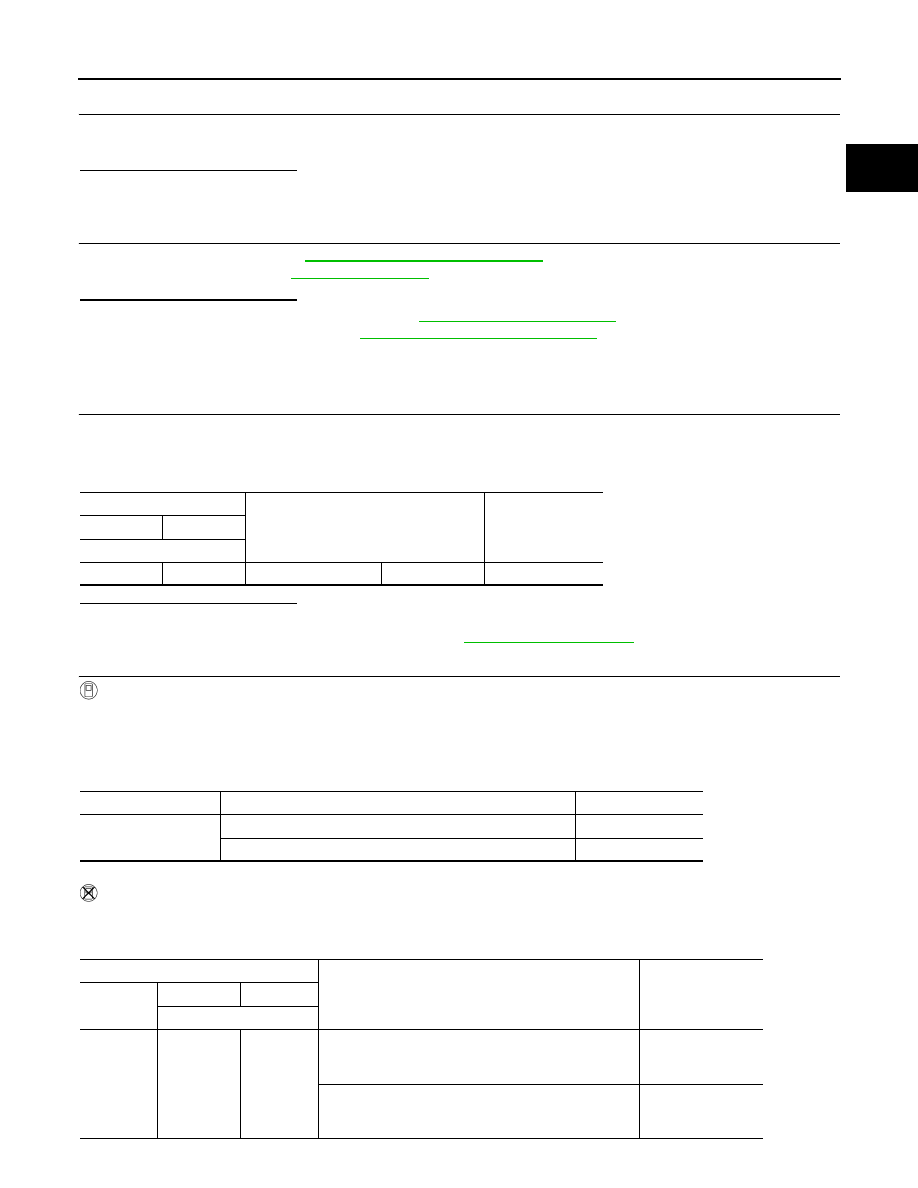

CHECK HIGH PRESSURE FUEL PUMP-1

1.

Turn ignition switch OFF.

2.

Disconnect high pressure fuel pump harness connector.

3.

check the resistance between high pressure fuel pump terminals as per the following conditions.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace high pressure fuel pump. Refer to

.

2.

CHECK HIGH PRESSURE FUEL PUMP-2

With CONSULT

1.

Reconnect high pressure fuel pump harness connector.

2.

Start engine.

3.

Select “FUEL PRES SEN V” in “DATA MONITOR” mode of “ENGINE” using CONSULT and check the

indication as per the following conditions.

Without CONSULT

1.

Start engine.

2.

Check fuel rail pressure sensor signal voltage.

High pressure fuel pump

Condition

Resistance

+

−

Terminal

1

2

Temperature [

°

C (

°

F)]

20 - 30 (68 - 86)

0.46 - 0.51

Ω

Monitor item

Condition

Indication

FUEL PRES SEN V

At idle

820 - 1,140 mV

Revving engine up to 4,000 rpm quickly.

820 - 2,900 mV

ECM

Condition

Voltage

(Approx.)

Connector

+

−

Terminal

F7

33

39

[Engine is running]

• Warm-up condition

• Idle speed

0.82 – 1.14 V

[Engine is running]

• Warm-up condition

• Engine speed: Revving engine from idle to 4,000 rpm

0.82 – 2.9 V