содержание .. 798 799 800 801 ..

Nissan X-Trail 32. Manual - part 800

P1078 EVT CONTROL POSITION SENSOR

EC-329

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Repair or replace malfunctioning part.

7.

CHECK EVT CONTROL POSITION SENSOR INPUT SIGNAL CIRCUIT

1.

Check the continuity between EVT control position sensor harness connector and ECM harness connec-

tor.

2.

Also check harness for short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair or replace malfunctioning part.

8.

CHECK EVT CONTROL POSITION SENSOR

Check the EVT control position sensor. Refer to

EC-329, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace EVT control position sensor. Refer to

9.

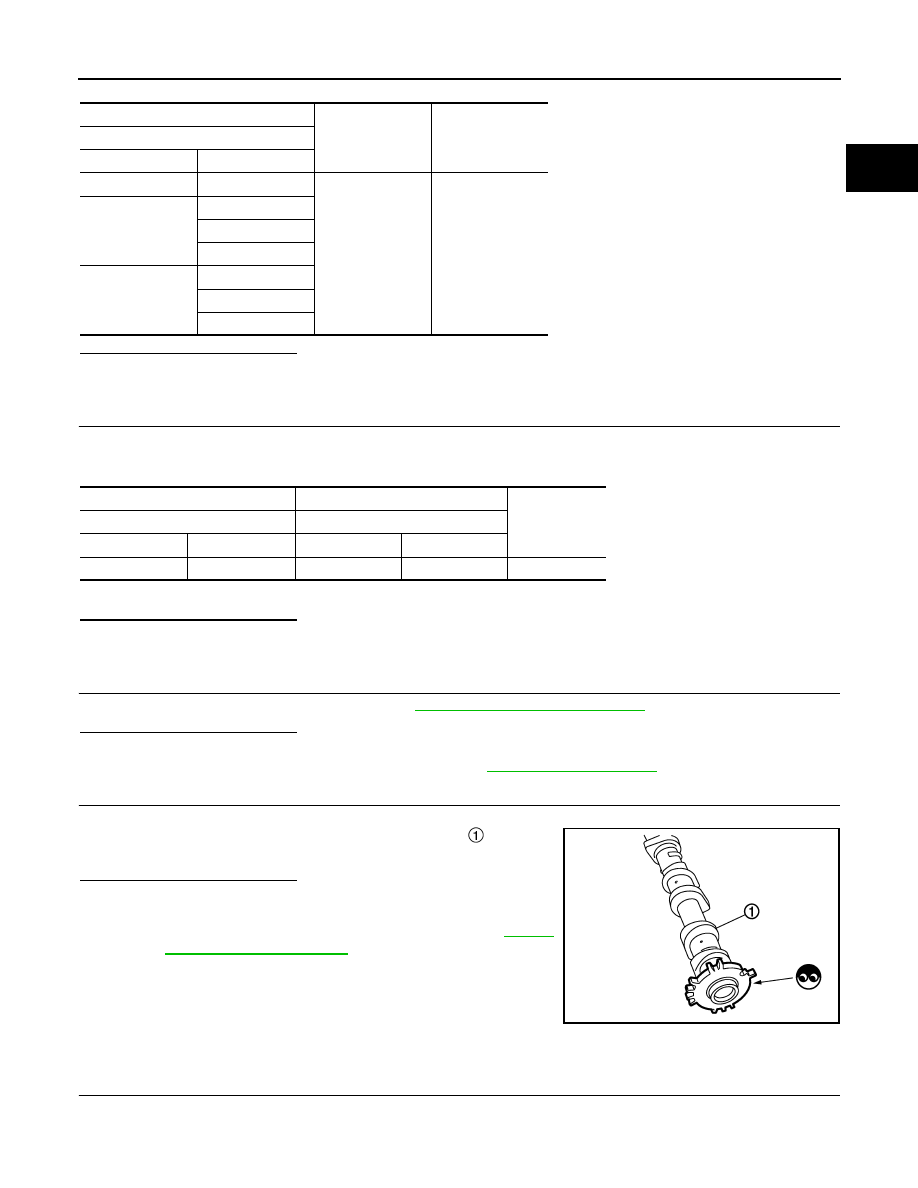

CHECK EXHAUST CAMSHAFT

Check the following.

• Accumulation of debris to the signal plate of camshaft

rear end

• Chipping signal plate of camshaft rear end

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Remove debris and clean the signal plate of cam-

shaftrear end or replace camshaft. Refer to

.

Component Inspection

INFOID:0000000010775226

1.

EXHAUST VALVE TIMING (EVT) CONTROL POSITION SENSOR-1

1.

Turn ignition switch OFF.

2.

Loosen the fixing bolt of the sensor.

+

–

Continuity

ECM

Connector

Terminal

F7

11

Ground

Existed

F8

54

55

56

E16

123

125

128

+

−

Continuity

EVT control position sensor

ECM

Connector

Terminal

Connector

Terminal

F104

3

F7

46

Existed

PBIA9557J