содержание .. 792 793 794 795 ..

Nissan X-Trail 32. Manual - part 794

P0520 EOP SENSOR

EC-305

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> GO TO 2.

2.

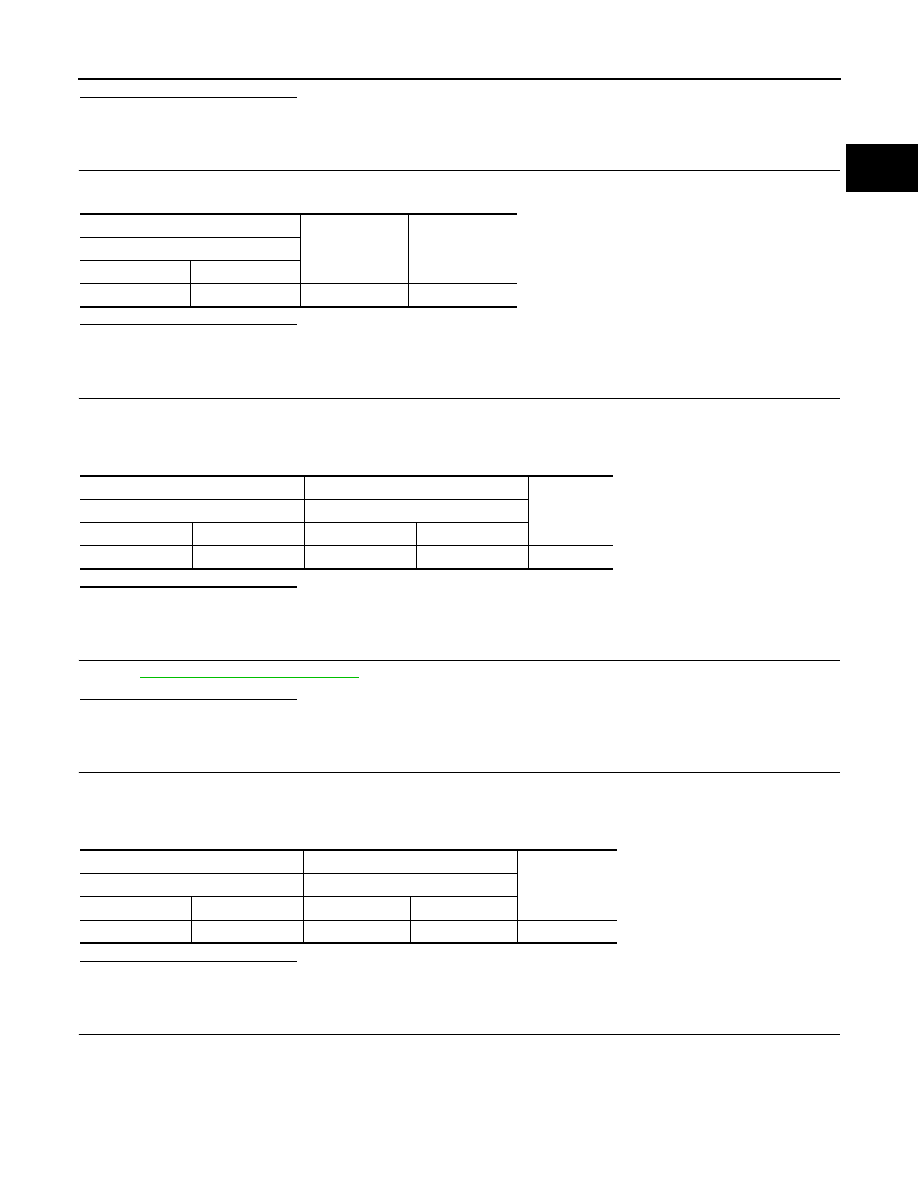

CHECK EOP SENSOR POWER SUPPLY CIRCUIT-2

Check the voltage between EOP sensor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 3.

3.

CHECK EOP SENSOR POWER SUPPLY CIRCUIT-3

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between EOP sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning part.

4.

CHECK SENSOR POWER SUPPLY 2 CIRCUIT

Perform

.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning part.

5.

CHECK EOP SENSOR GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between EOP sensor harness connector and ECM harness connector.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair or replace malfunctioning part.

6.

CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

+

−

Voltage

(Approx.)

EOP sensor

Connector

Terminal

F106

3

Ground

5 V

+

−

Continuity

EOP sensor

ECM

Connector

Terminal

Connector

Terminal

F106

3

F7

23

Existed

+

−

Continuity

EOP sensor

ECM

Connector

Terminal

Connector

Terminal

F106

1

F7

39

Existed