содержание .. 783 784 785 786 ..

Nissan X-Trail 32. Manual - part 785

P0300, P0301, P0302, P0303, P0304 MISFIRE

EC-269

< DTC/CIRCUIT DIAGNOSIS >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0301, P0302, P0303, P0304

Not applicable

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

Will CONSULT be used?

YES

>> GO TO 2.

NO

>> GO TO 4.

2.

PERFORM DTC CONFIRMATION PROCEDURE-1

WITH CONSULT

1.

Start engine and warm it up to normal operating temperature.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Restart engine and let it idle for about 35 minutes.

4.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Proceed to

.

NO

>> GO TO 3.

3.

PERFORM DTC CONFIRMATION PROCEDURE-2

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Start engine and drive the vehicle under similar conditions to (1st trip) Freeze Frame Data for a certain

time. Refer to the table below.

Hold the accelerator pedal as steady as possible.

Similar conditions to (1st trip) Freeze Frame Data mean that the following conditions should be satisfied at

the same time.

Driving time varies according to the engine speed in the freeze frame data.

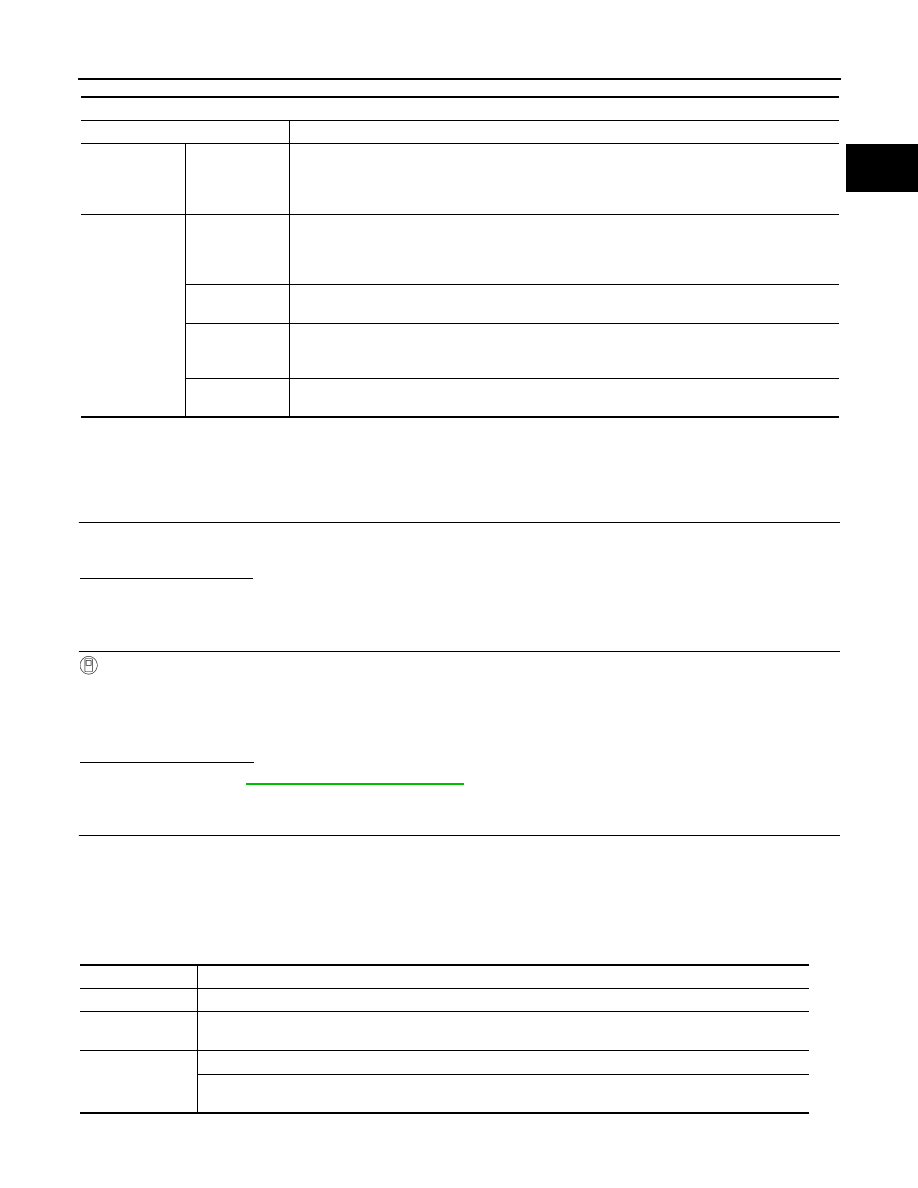

Engine operating condition in fail-safe mode

Fail safe mode

Vehicle behavior

Traveling con-

trol mode

Accelerator an-

gle variation

control

ECM controls the accelerator pedal depression speed to make it slower than actual speed. This

causes a drop in accelerating performance and encourages the driver to repair malfunction.

NOTE:

ECM does not control the accelerator pedal releasing speed.

Combustion

control mode

Stratified charge

combustion

control at start-

ing

No stratified charge combustion at starting (cold start).

Idle speed con-

trol

Stops feedback control of idle speed and controls with specified speed.

Recovery speed

control at decel-

erating

Stops recovery speed control by the fuel cut at decelerating and controls with specified speed.

Idle neutral con-

trol

Stops idle neutral control.

Engine speed

Engine speed in the freeze frame data

±

400 rpm

Vehicle speed

Vehicle speed in the freeze frame data

±

10 km/h (6 MPH)

Base fuel sched-

ule

Base fuel schedule in the freeze frame data

±

10%

Engine coolant

temperature (T)

condition

When the freeze frame data shows lower than 70

°

C (158

°

F), T should be lower than 70

°

C (158

°

F).

When the freeze frame data shows higher than or equal to 70

°

C (158

°

F), T should be higher than or equal

to 70

°

C (158

°

F).