содержание .. 669 670 671 672 ..

Nissan X-Trail 32. Manual - part 671

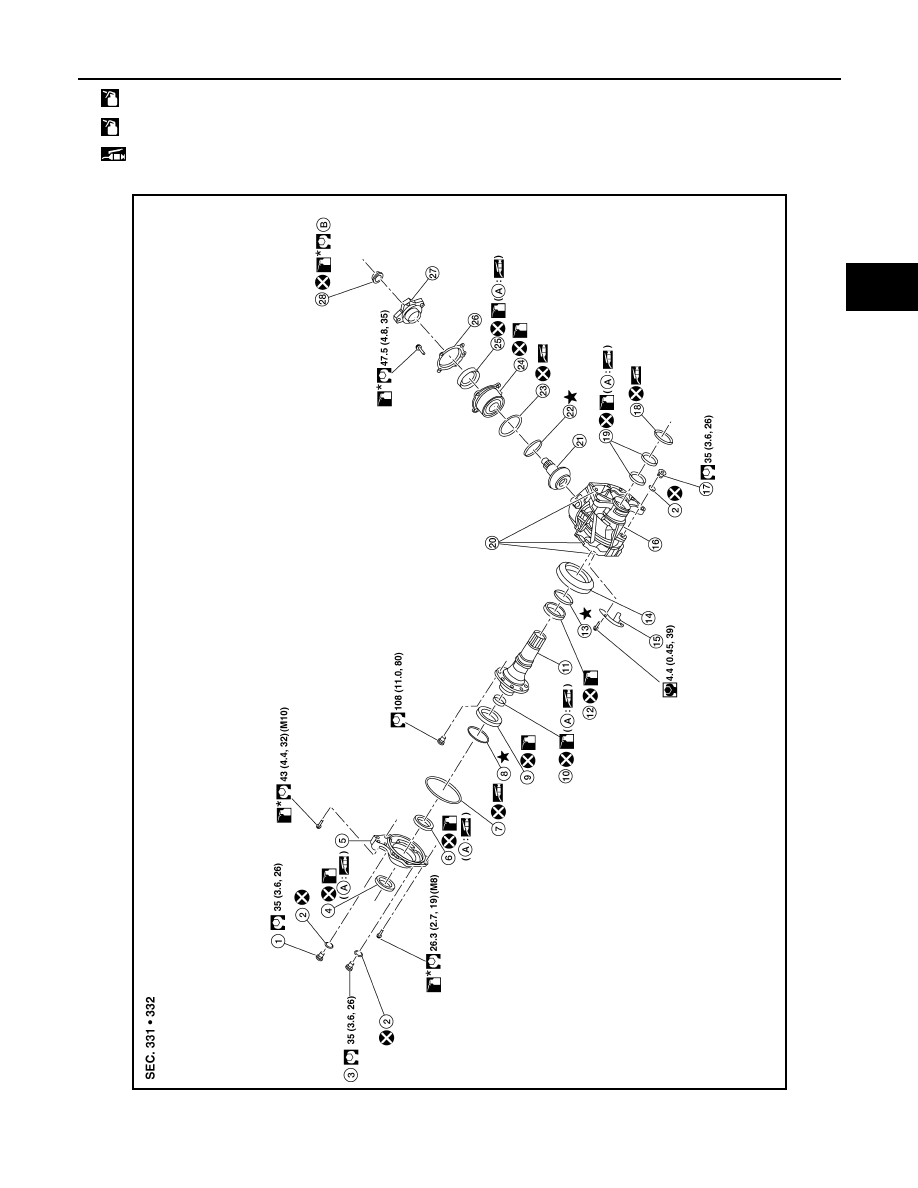

DRIVE PINION

DLN-95

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

QR25DE models

: Apply transfer oil.

*

: Apply anti-corrosive oil.

: Apply multi-purpose grease.

AWDIA1138ZZ