содержание .. 213 214 215 216 ..

Nissan X-Trail 32. Manual - part 215

CORROSION PROTECTION

BRM-21

< REMOVAL AND INSTALLATION >

[FOR EUROPE (LHD)]

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

REMOVAL AND INSTALLATION

CORROSION PROTECTION

Description

INFOID:0000000010843422

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

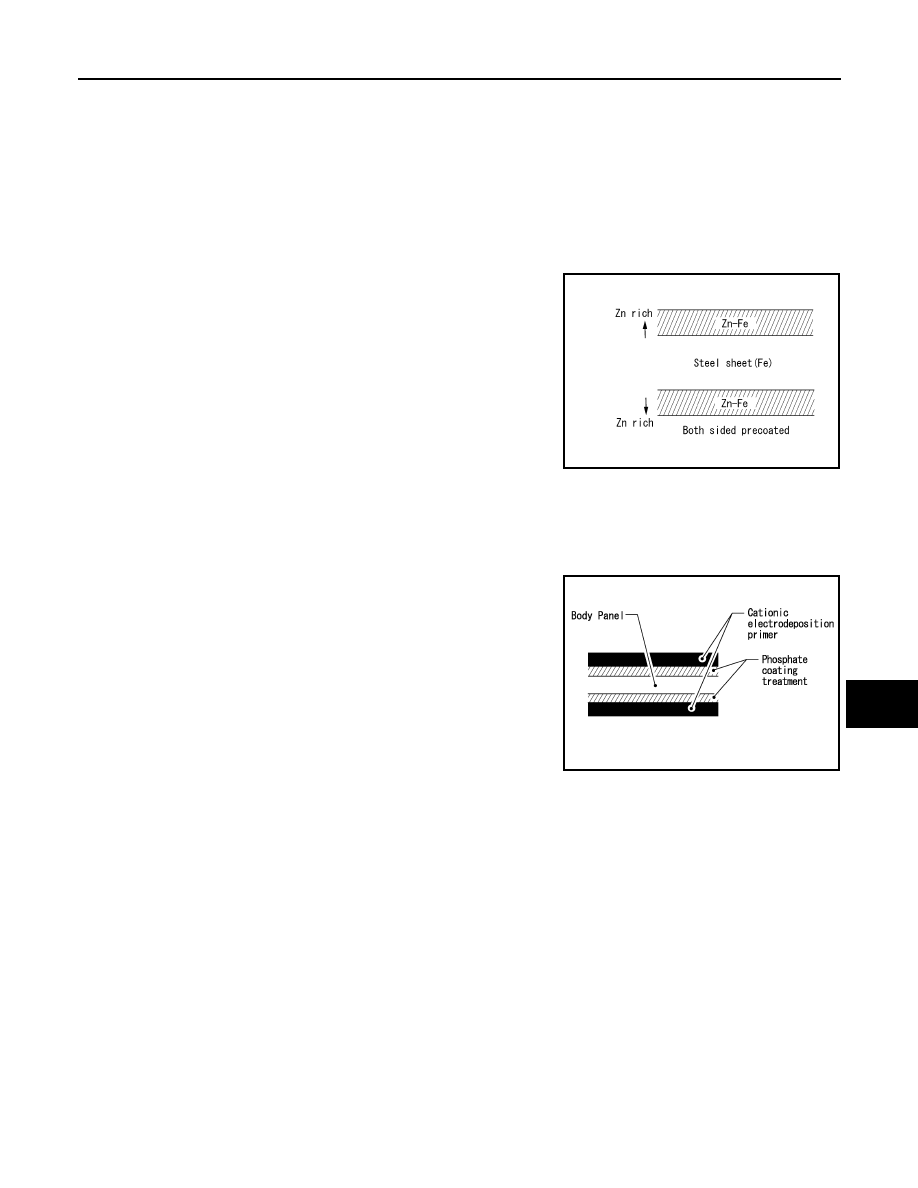

Anti-Corrosive Precoated Steel (Galvannealed Steel)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet is adopted replacing conventional

zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

NISSAN genuine parts are fabricated from galvannealed steel. Therefore, it is recommended that NISSAN

genuine parts or an equivalent be used for panel replacement to maintain the anti-corrosive performance built

into the vehicle at the factory.

Phosphate Coating Treatment and Cationic Electrodeposition Primer

A phosphate coating treatment and a cationic electrodeposition

primer, which provide excellent corrosion protection, are applied to

all body components.

CAUTION:

Confine paint removal during welding operation to an absolute

minimum.

NISSAN genuine parts are also treated in the same manner. Therefore, it is recommended that NISSAN gen-

uine parts or an equivalent be used for panel replacement to maintain anti-corrosive performance built into the

vehicle at the factory.

Undercoating

INFOID:0000000010860040

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoat-

ing which is rust resistant, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1.

Never apply undercoating to any place unless specified (such as the areas above the muffler and three

way catalyst that are subjected to heat).

2.

Never undercoat the exhaust pipe or other parts that become hot.

3.

Never undercoat rotating parts.

4.

Apply bitumen wax after applying undercoating.

5.

After putting seal on the vehicle, put undercoating on it.

SIIA2294E

PIIA0095E