содержание .. 1871 1872 1873 1874 ..

Nissan X-Trail 32. Manual - part 1873

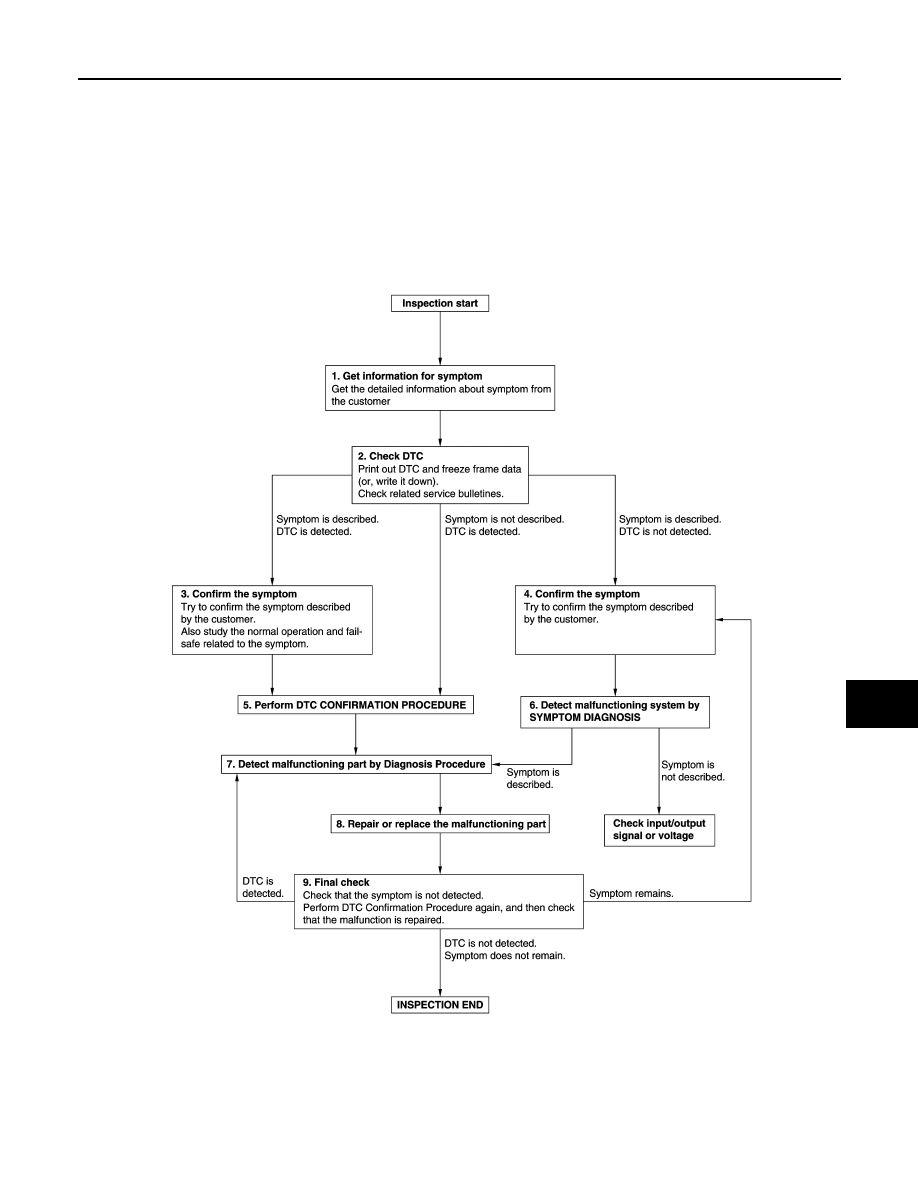

DIAGNOSIS AND REPAIR WORK FLOW

SEC-259

< BASIC INSPECTION >

[WITHOUT INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

M

A

B

SEC

N

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

INFOID:0000000010922273

OVERALL SEQUENCE

DETAILED FLOW

JMKIA8652GB