содержание .. 1770 1771 1772 1773 ..

Nissan X-Trail 32. Manual - part 1772

RSU-10

< REMOVAL AND INSTALLATION >

COIL SPRING

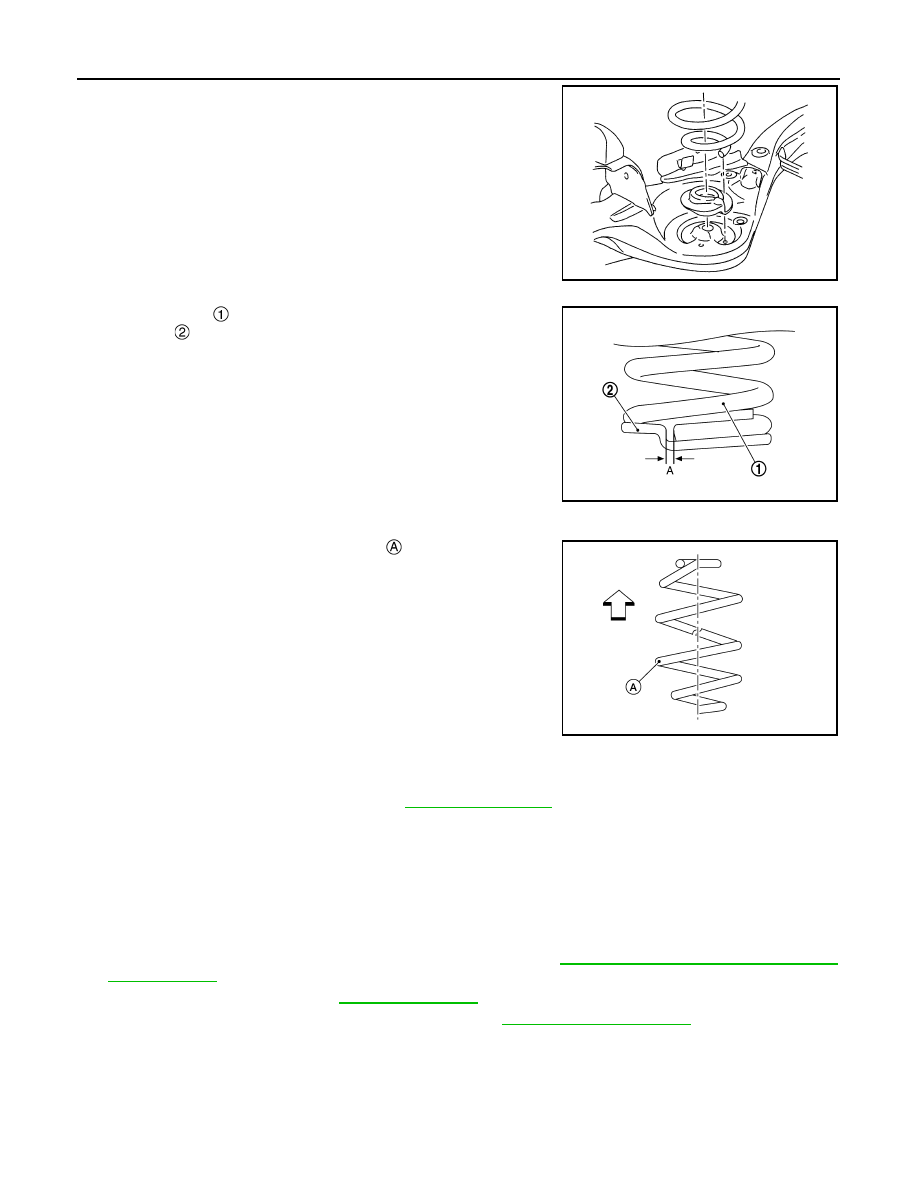

• Securely install coil spring with the lower end aligned with the

steps of lower rubber seat.

CAUTION:

The lower rubber seat protrusion must be securely inserted

into the hole of rear suspension arm.

• Install coil spring

by aligning lower end of coil spring with lower

rubber seat

as shown in the figure.

CAUTION:

Set coil spring so that its paint mark

is aligned with the

position of 1.75 turns from the bottom end of the coil spring.

• Perform final tightening of fixing parts at the vehicle installation position (rubber bushing), under unladen

conditions with tires on level ground.

• Perform inspection after installation. Refer to

Inspection

INFOID:0000000010822780

INSPECTION AFTER REMOVAL

Check rear lower link, rubber seat, upper seat, and coil spring for deformation, crack, and damage. Replace it

if necessary.

INSPECTION AFTER INSTALLATION

1.

Check wheel sensor harness for proper connector. Refer to

.

2.

Check wheel alignment. Refer to

3.

Adjust neutral position of steering angle sensor. Refer to

.

SEIA0636J

Dimension (A)

: 5 mm (0.20 in) or less

JSEIA0671ZZ

ALEIA0210ZZ