содержание .. 1406 1407 1408 1409 ..

Nissan X-Trail 32. Manual - part 1408

BLOWER MOTOR

HAC-107

< DTC/CIRCUIT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONING]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

BLOWER MOTOR

Diagnosis Procedure

INFOID:0000000010939764

1.

CHECK FUSE

1.

Turn ignition switch OFF.

2.

Check following fuses.

-

15 A fuse [Nos. 17 and 27, located in fuse block (J/B)]

NOTE:

Refer to

PG-84, "Fuse, Connector and Terminal Arrangement"

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.

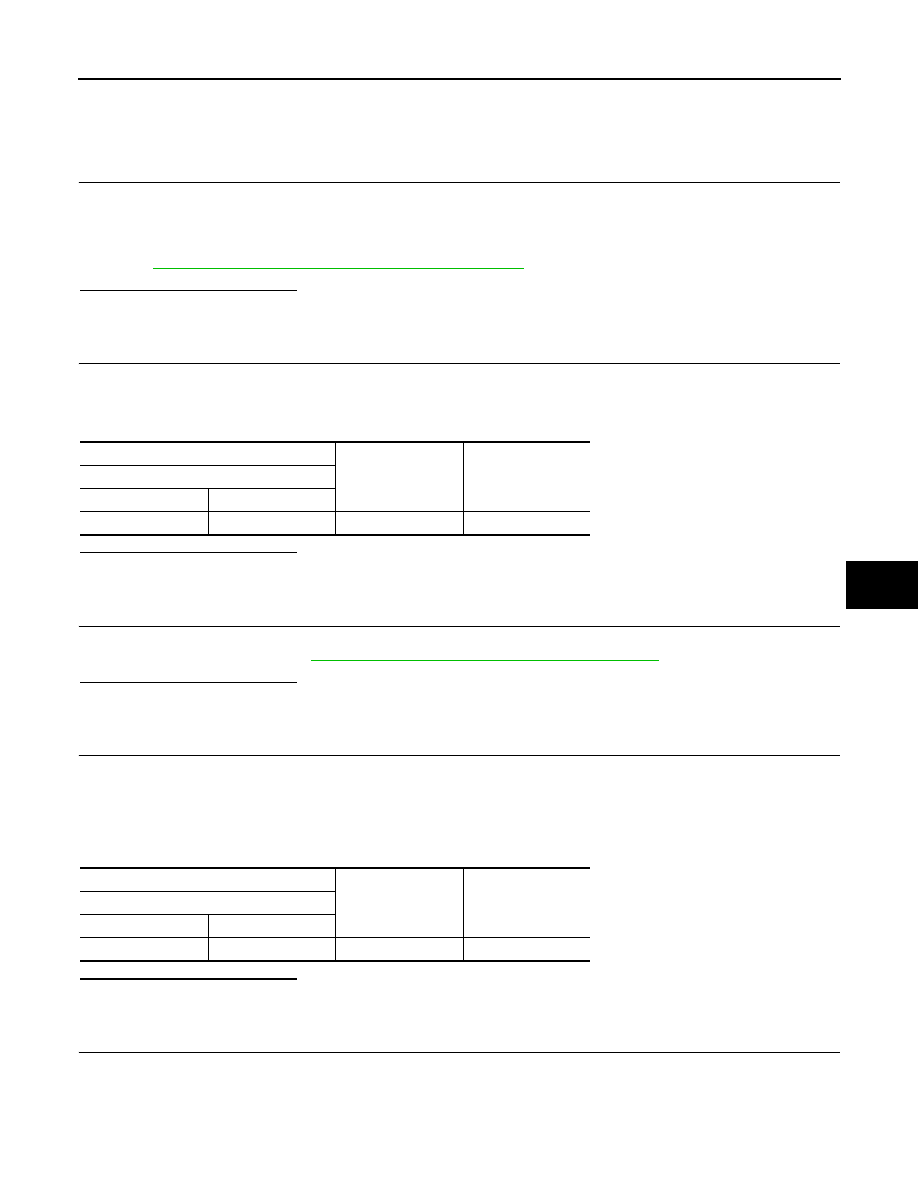

CHECKPOWER TRANSISTOR POWER SUPPLY

1.

Disconnect power transistor connector.

2.

Turn ignition switch ON.

3.

Check voltage between power transistor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

CHECK BLOWER RELAY

1.

Turn ignition switch OFF.

2.

Check blower relay. Refer to

HAC-110, "Component Inspection (Blower Relay)"

Is the inspection result normal?

YES

>> Repair harness or connector between power transistor and fuse.

NO

>> Replace blower relay.

4.

CHECK BLOWER MOTOR CONTROL CIRCUIT

1.

Turn ignition switch OFF.

2.

Connect power transistor connector.

3.

Disconnect blower motor connector.

4.

Turn ignition switch ON.

5.

Check voltage between blower motor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> GO TO 5.

5.

CHECK BLOWER MOTOR CONTROL CIRCUIT FOR OPEN

1.

Turn ignition switch OFF.

2.

Disconnect power transistor connector.

3.

Check continuity between power transistor harness connector and blower motor harness connector.

+

−

Voltage

Power transistor

Connector

Terminal

M349

4

Ground

Battery voltage

+

−

Voltage

Blower motor

Connector

Terminal

M347

1

Ground

Battery voltage