содержание .. 1027 1028 1029 1030 ..

Nissan X-Trail 32. Manual - part 1029

PREPARATION

EM-13

< PREPARATION >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

EM03470000

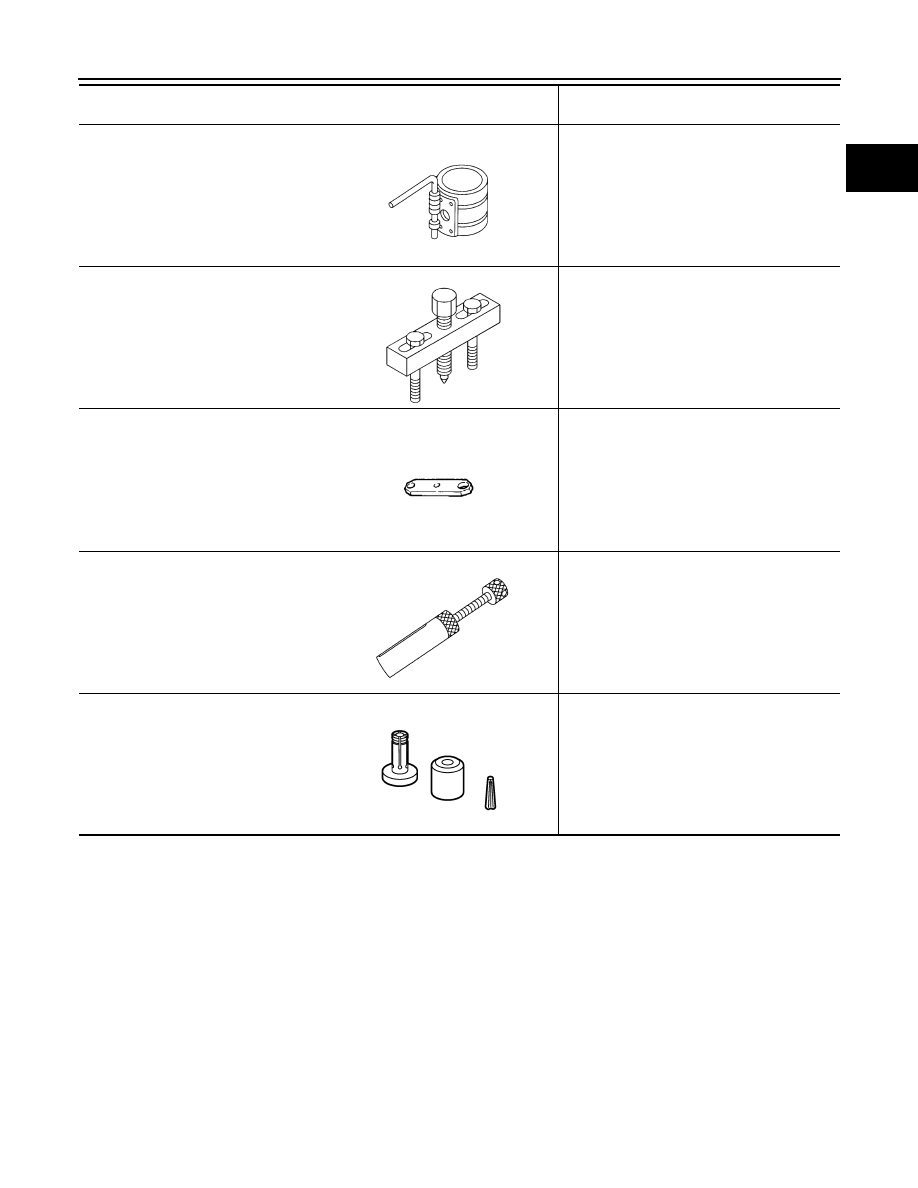

Piston ring compressor

Installing piston assembly into cylinder bore

KV11103000

Pulley puller

Removing crankshaft pulley

KV11105210

Stopper plate

Fixing drive plate and flywheel

KV10119600

Injector remover

Removing fuel injector

KV101197S0

Injector seal drift set

Installing fuel injector seal ring

Tool number

Tool name

Description

S-NT044

NT676

ZZA0009D

JPBIA3746ZZ

JPBIA3281ZZ