Qashqai J11. Roof - part 2

POWER SUPPLY AND GROUND CIRCUIT

RF-17

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

L

M

A

B

RF

N

O

P

YES

>> GO TO 5.

NO

>> Repair or replace harness.

5.

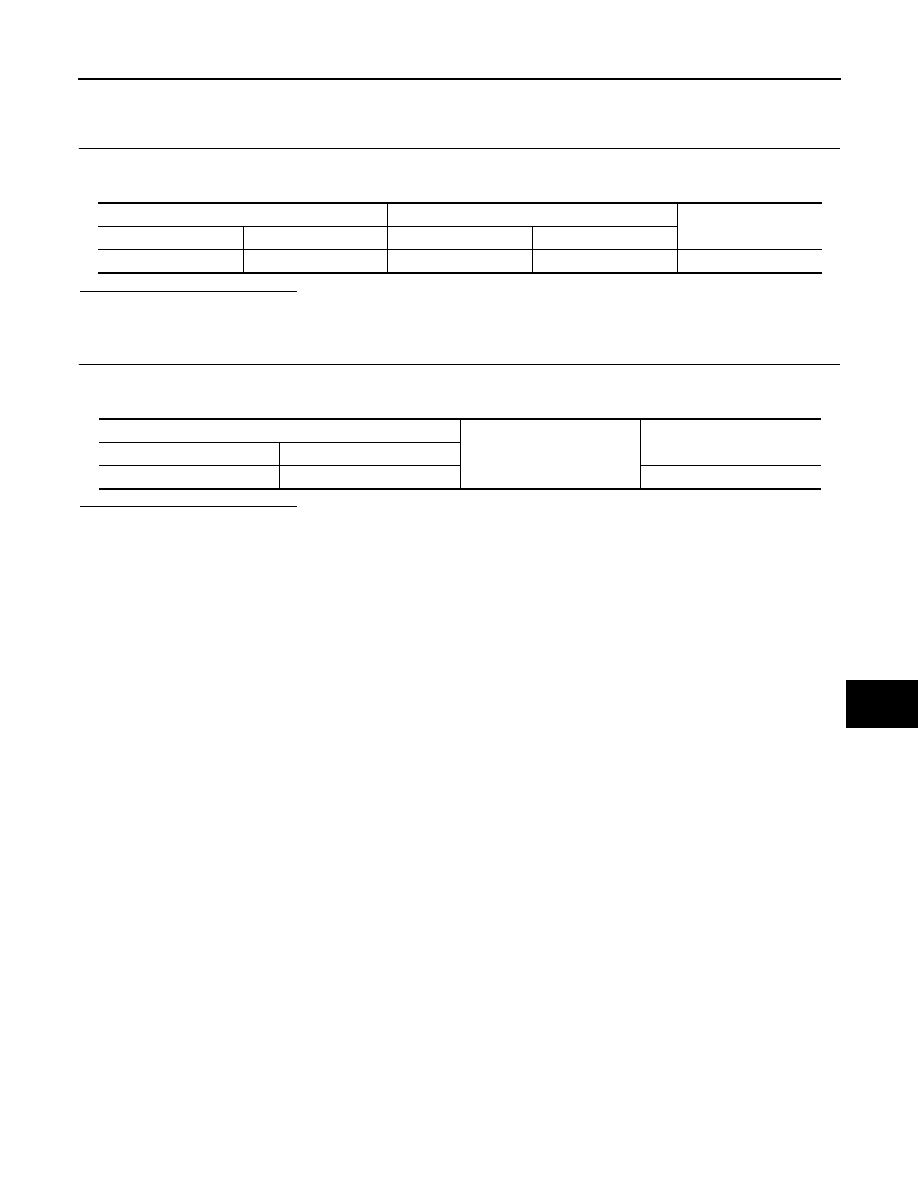

CHECK SUNSHADE MOTOR ASSEMBLY POWER SUPPLY CIRCUIT 2

Check continuity between circuit breaker harness connector and sunshade motor assembly harness connec-

tor.

Is the inspection result normal?

YES

>> Replace circuit breaker.

NO

>> Repair or replace harness.

6.

CHECK SUNSHADE MOTOR ASSEMBLY GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Check continuity between sunshade motor assembly harness connector and ground.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Repair or replace harness.

Circuit breaker

Sunshade motor assembly

Continuity

Connector

Terminal

Connector

Terminal

M86

2

R11

7

Existed

Sunshade motor assembly

Ground

Continuity

Connector

Terminal

R11

1

Existed