Qashqai J11. Front axle - part 4

FRONT WHEEL HUB AND KNUCKLE

FAX-49

< REMOVAL AND INSTALLATION >

[4WD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

REMOVAL AND INSTALLATION

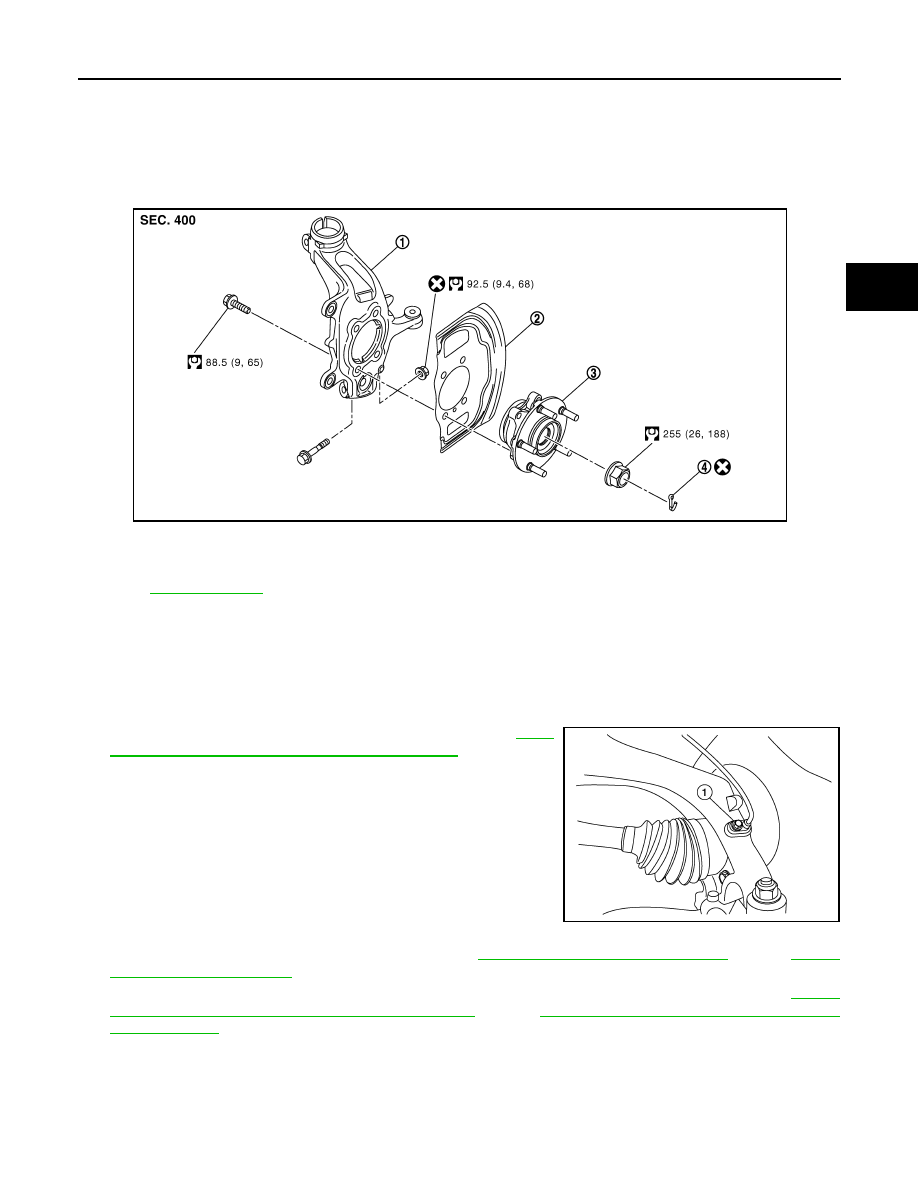

FRONT WHEEL HUB AND KNUCKLE

Exploded View

INFOID:0000000010297864

Removal and Installation

INFOID:0000000010297865

REMOVAL

Wheel hub

1.

emove tires from vehicle.

2.

Remove wheel sensor (1) from steering knuckle. Refer to

138, "FRONT WHEEL SENSOR : Exploded View"

CAUTION:

• Failure to separate the front wheel sensor from the steer-

ing knuckle may result in damage to the front wheel sen-

sor.

• Never pull on wheel sensor harness.

3.

Remove lock plate from strut assembly. Refer to

BR-19, "FRONT : Exploded View"

(LHD),

4.

Remove torque member mounting bolts. Hang torque member not to interfere with work. Refer to

"BRAKE CALIPER ASSEMBLY : Exploded View"

(LHD),

BR-80, "BRAKE CALIPER ASSEMBLY :

(RHD).

CAUTION:

Never depress brake pedal while brake caliper is removed.

5.

Remove disc rotor.

6.

Remove cotter pin, and then loosen hub lock nut.

1.

Steering knuckle

2.

Splash guard

3.

Wheel hub and bearing assembly

4.

Cotter pin

Refer to

E1DIA0224GB

ALDIA0526ZZ