Qashqai J11. Body repair - part 16

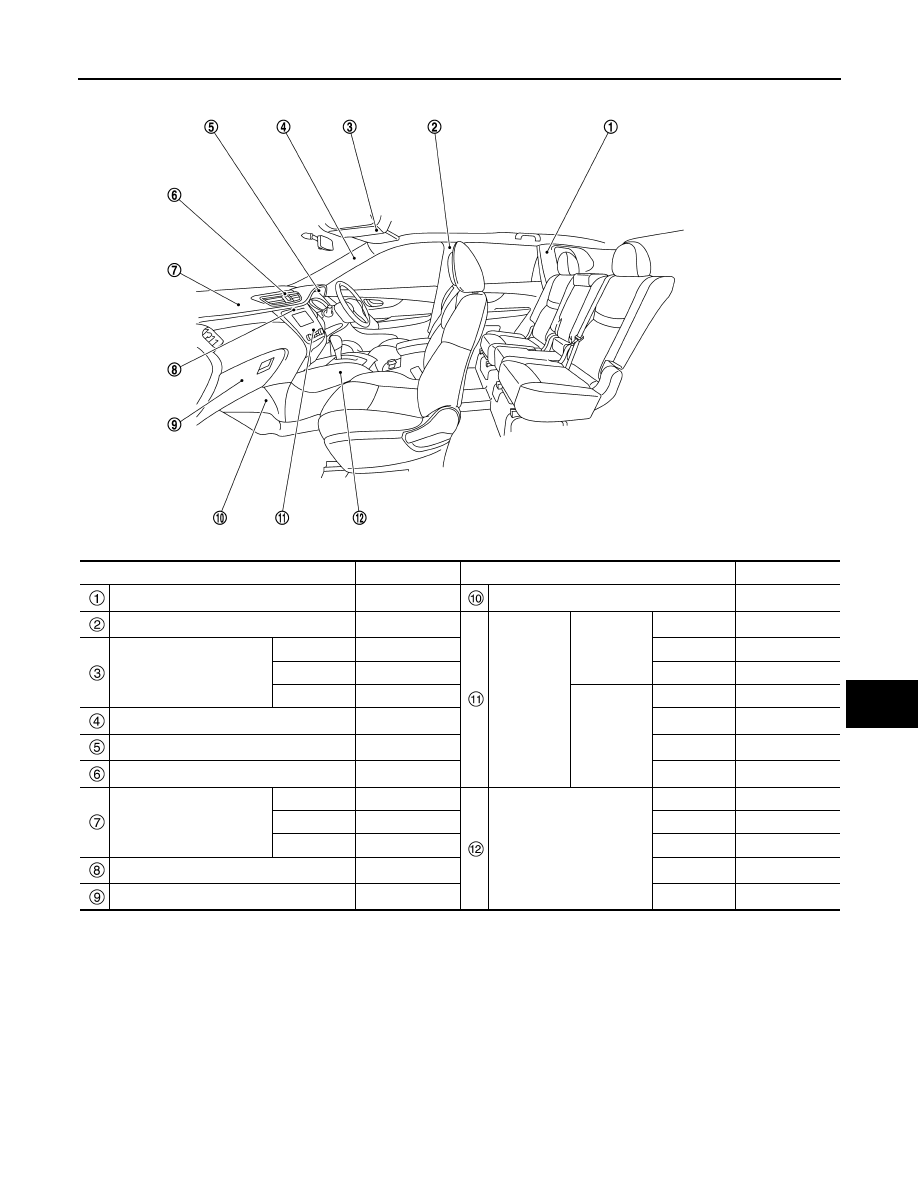

LOCATION OF PLASTIC PARTS

BRM-241

< SERVICE DATA AND SPECIFICATIONS (SDS)

[FOR EUROPE (RHD)]

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

Component

Material

Component

Material

Rear pillar finisher

PP

Instrument lower cover

PP + EPDM

Center pillar garnish

PP

A/C Control

Manual A/C

Finisher

PC + ABS

Map lamp

Lens

PC

Switch

PC

Housing

PP

Case

ABS

Finisher

PP

Auto A/C

Finisher

PC + ABS

Front pillar garnish

PP

Switch

PC

Cluster lid A

PP

Case

PC + ABS

Center ventilator finisher

PC + ABS

Lens

PC

Instrument panel

Skin

TPO

Center console

Body

PP + EPDM

Pad

PUR

Console box

PP

Core

PP + EPDM

Inner lid

PP + EPDM

Cluster lid C

PC + ABS

Insert lid

PC + ABS

Glove box

PP

Cup holder

PP + EPDM

JSKIA3978ZZ