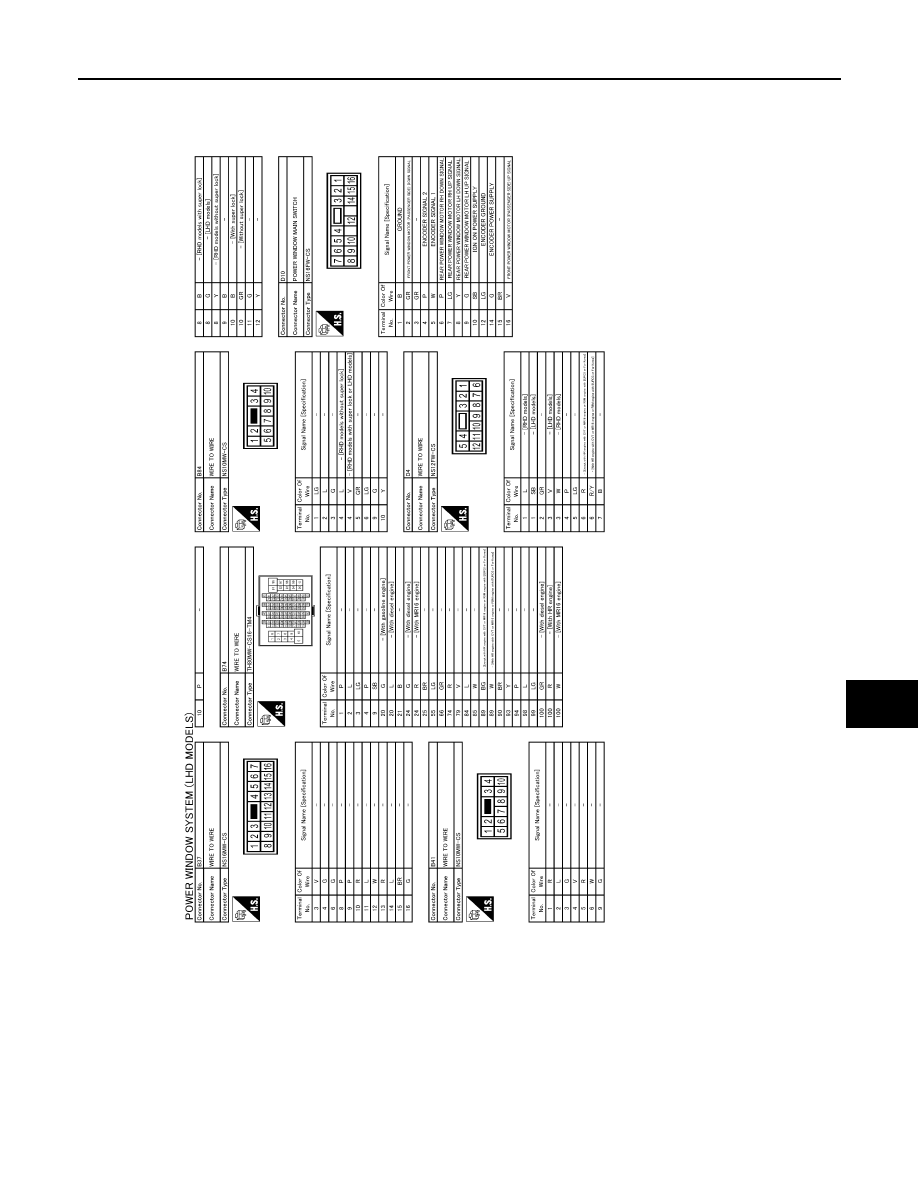

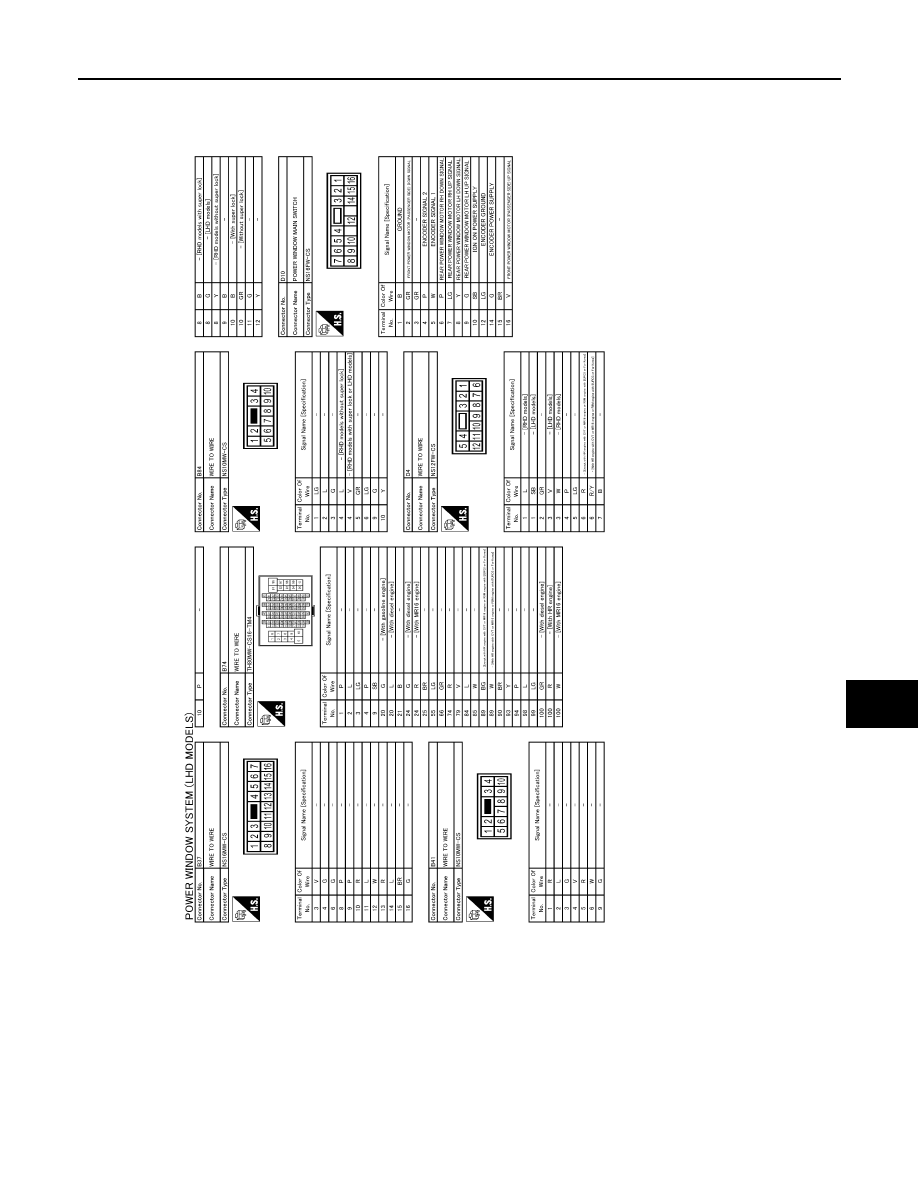

Qashqai J11. Power window control system - part 2

POWER WINDOW SYSTEM

PWC-17

< WIRING DIAGRAM >

C

D

E

F

G

H

I

J

L

M

A

B

PWC

N

O

P

JRKWE4033GB

|

|

|

POWER WINDOW SYSTEM PWC-17 < WIRING DIAGRAM > C D E F G H I J L M A B PWC N O P JRKWE4033GB |