Qashqai J11. Heater & Air conditioning System - part 2

SYSTEM

HA-17

< SYSTEM DESCRIPTION >

[TYPE 1]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

SYSTEM

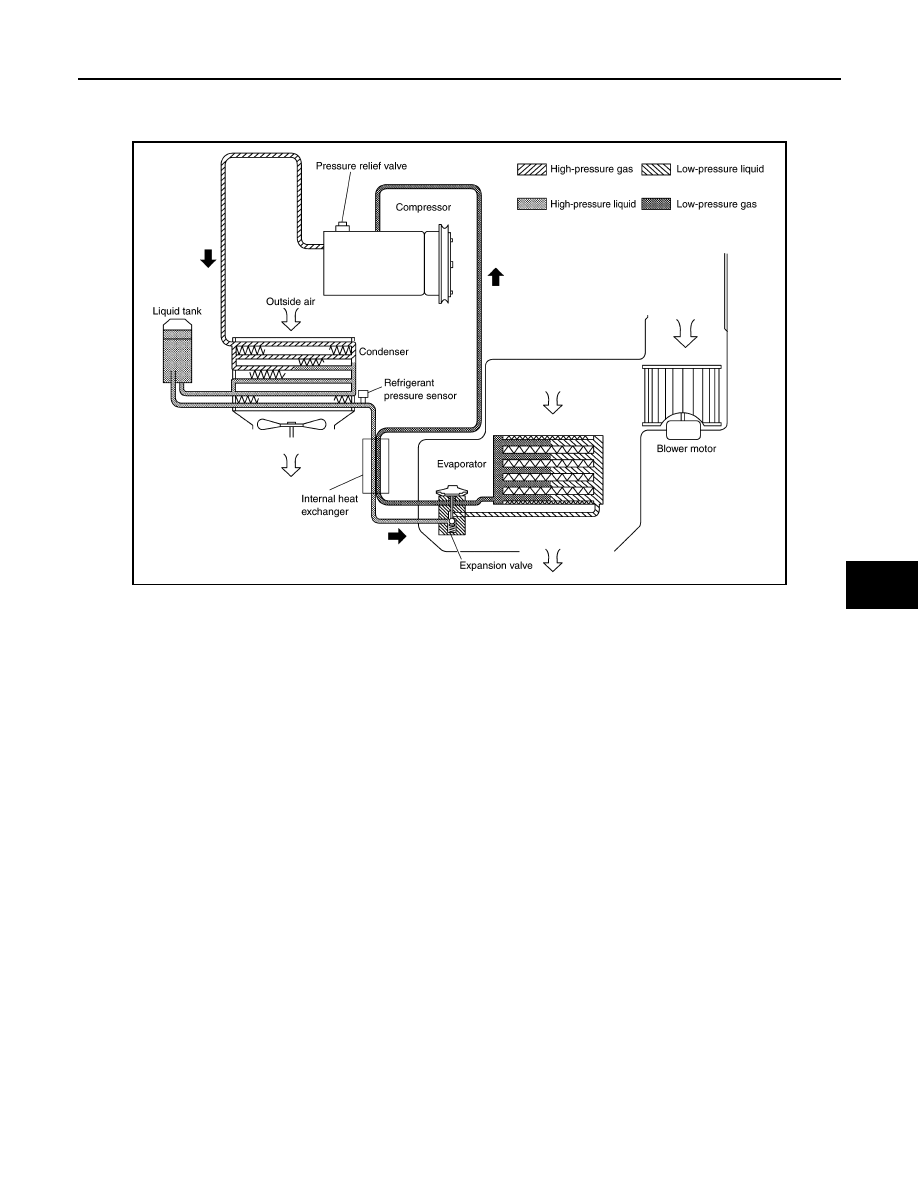

System Diagram

INFOID:0000000010451964

System Description

INFOID:0000000010451965

REFRIGERANT CYCLE

Refrigerant Flow

The refrigerant from the compressor, flows the condenser with liquid tank, the evaporator, and returns to the

compressor. The refrigerant evaporation in the evaporator is controlled by an expansion valve.

Freeze Protection

When intake sensor detects that evaporator surface temperature is 2

°

C (36

°

F) or less, A/C auto amp. (Auto-

matic air conditioning) or A/C amp. (Manual air conditioning) requests ECM to turn the compressor OFF, and

ECM makes A/C relay to OFF, and stops the compressor.

REFRIGERANT SYSTEM PROTECTION

Refrigerant Pressure Sensor

• The refrigerant system is protected against excessively high- or low-pressures by the refrigerant pressure

sensor, installed at the high-pressure pipe 1. The refrigerant pressure sensor detects the pressure inside the

refrigerant line and sends the voltage signal to the ECM if the system pressure rises above, or falls below

the specifications.

• ECM turns the A/C relay to OFF and stops the compressor when the high-pressure side detected by refriger-

ant pressure sensor is following conditions;

- Approximately 3,120 kPa (31.2 bar, 31.8 kg/cm

2

, 452 psi) or more (Engine speed is less than 1,500 rpm.)

- Approximately 2,740 kPa (27.4 bar, 27.9 kg/cm

2

, 397 psi) or more (Engine speed is 1,500 rpm or more.)

- Approximately 140 kPa (1.4 bar, 1.4 kg/cm

2

, 20 psi) or less

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

The release port on the pressure relief valve automatically opens and releases refrigerant into the atmosphere

when the pressure of refrigerant in the system increases to an unusual level [more than 3,800 kPa (38 bar,

38.8 kg/cm

2

, 551 psi)].

JMIIA3115GB