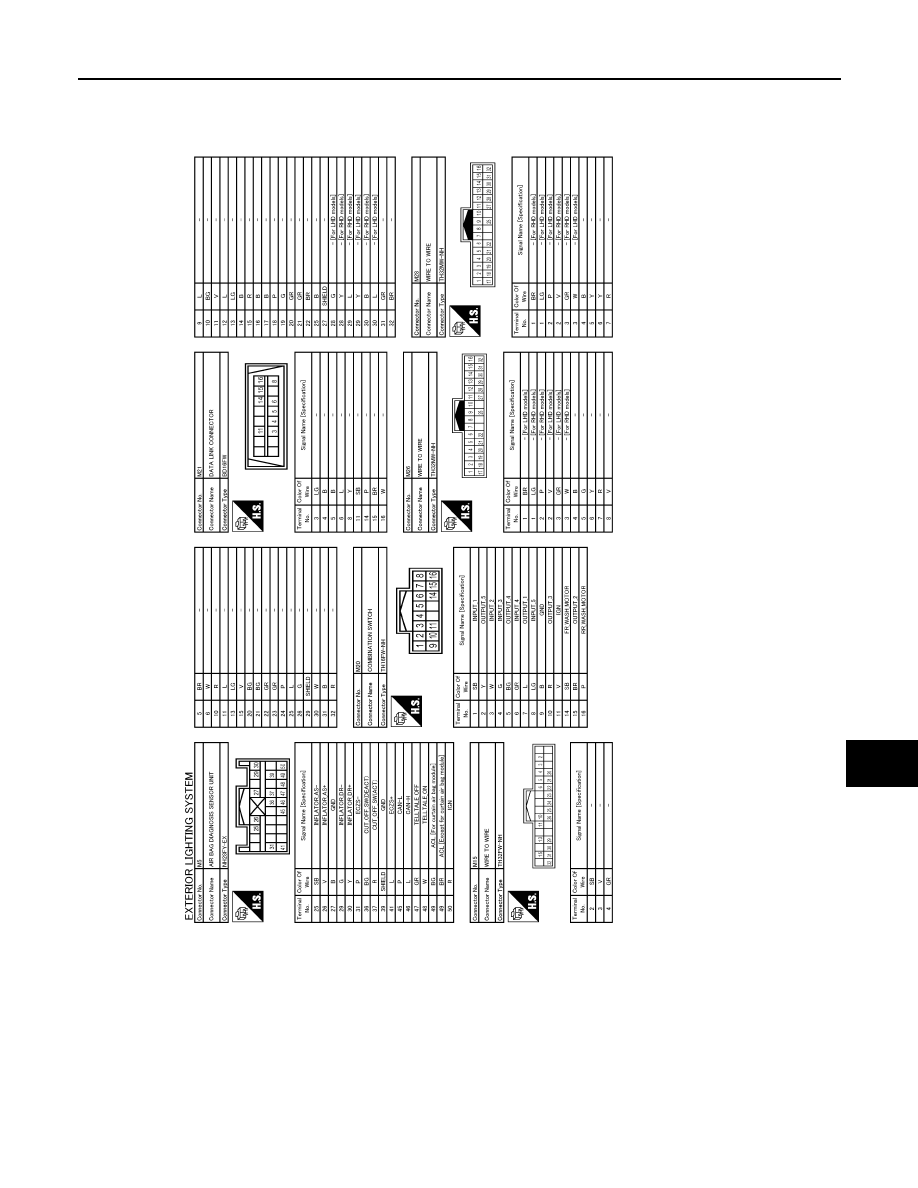

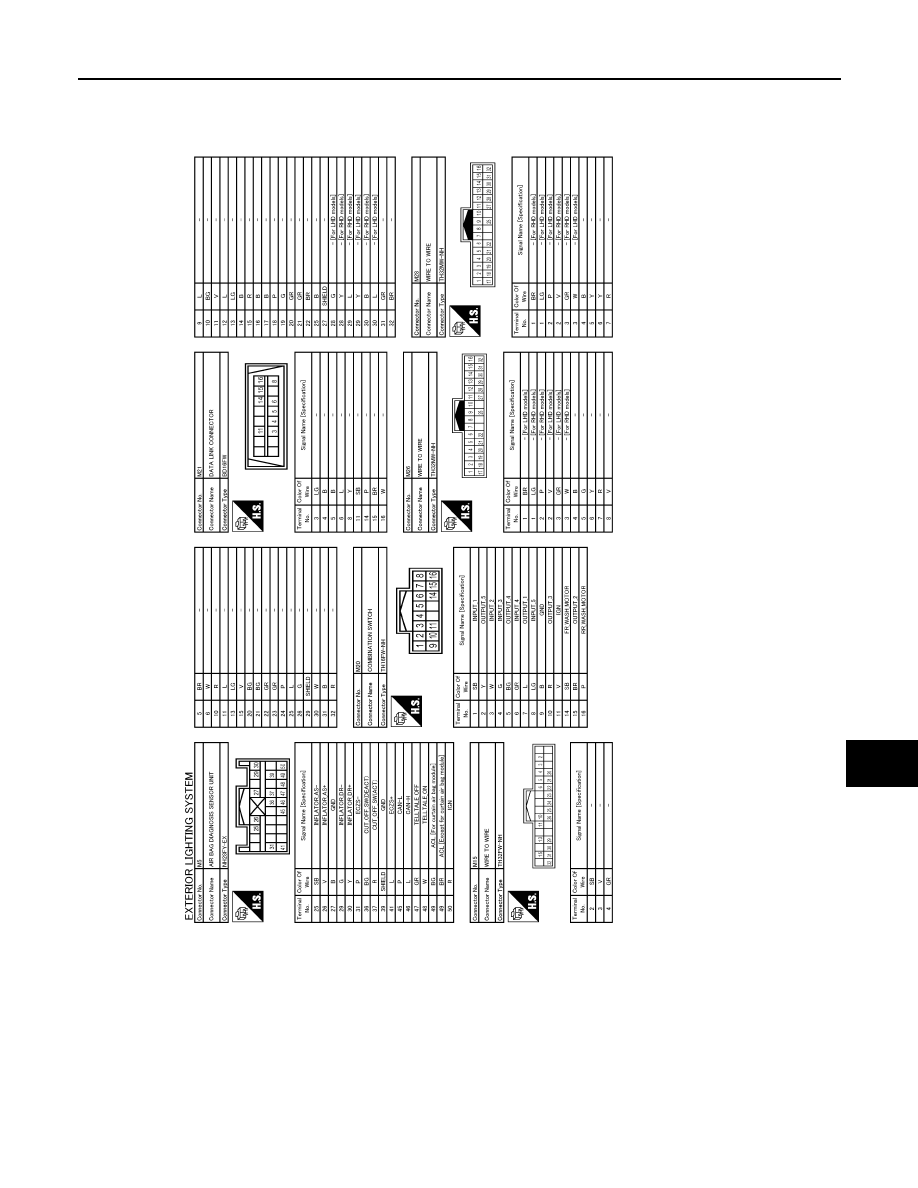

Qashqai J11. Exterior Lighting system - part 5

EXTERIOR LIGHTING SYSTEM

EXL-65

< WIRING DIAGRAM >

[LED HEADLAMP]

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

JRLWD2228GB

|

|

|

EXTERIOR LIGHTING SYSTEM EXL-65 < WIRING DIAGRAM > [LED HEADLAMP] C D E F G H I J K M A B EXL N O P JRLWD2228GB |