Qashqai J11. Exhaust system (HRA2DDT, K9K, MR20DD) - part 2

PARTICLE FILTER

EX-17

< REMOVAL AND INSTALLATION >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EX

N

P

O

PARTICLE FILTER

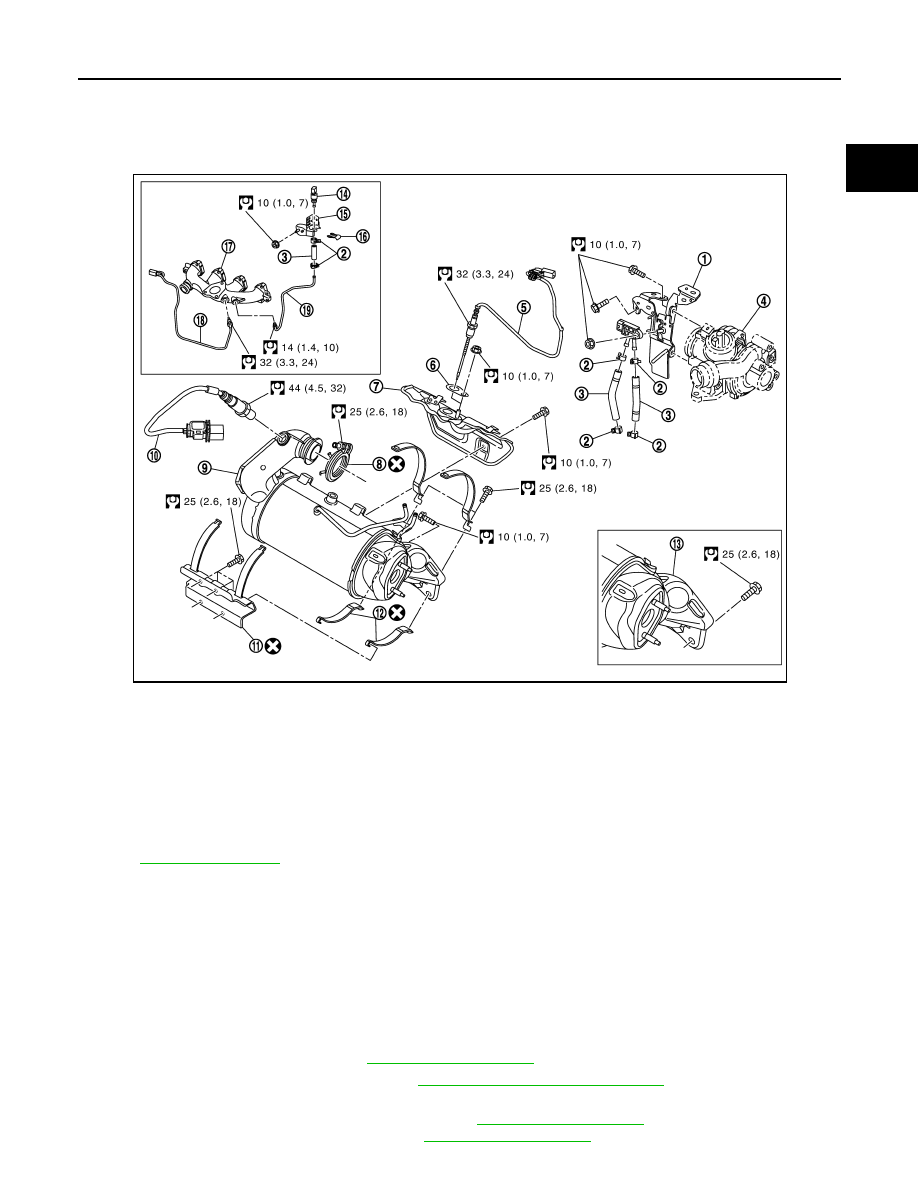

Exploded View

INFOID:0000000010427908

Removal and Installation

INFOID:0000000010427909

CAUTION:

• Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance and shape.

• Perform the operation with the exhaust system fully cooled down because the system is still hot just

after the engine stops.

• Be careful not to cut your hand on the insulator edge.

REMOVAL

1.

Remove exhaust front tube. Refer to

.

2.

Remove front suspension member. Refer to

FSU-21, "Removal and Installation"

3.

Unclip and move aside:

• exhaust gas temperature sensor harness. Refer to

.

• DPF temperature sensor harness. Refer to

1.

DPF pressure sensor bracket

2.

Clamp

3.

Hose

4.

Turbocharger

5.

DPF temperature sensor

6.

Gasket

7.

DPF heat insulator

8.

V-band clamp

9.

Diesel Particle Filter

10. DPF oxygen sensor

11. DPF Bracket

12. DPF bracket strip

13. DPF exhaust gas exit

14. Exhaust gas pressure sensor

15. Exhaust gas pressure sensor bracket

16. Lock plate

17. Exhaust manifold

18. Exhaust gas temperature sensor

19. Exhaust gas pressure sensor tube

E1BIA0896GB