Qashqai J11. Engine mechanical (HRA2DDT, K9K, MR20DD) - part 8

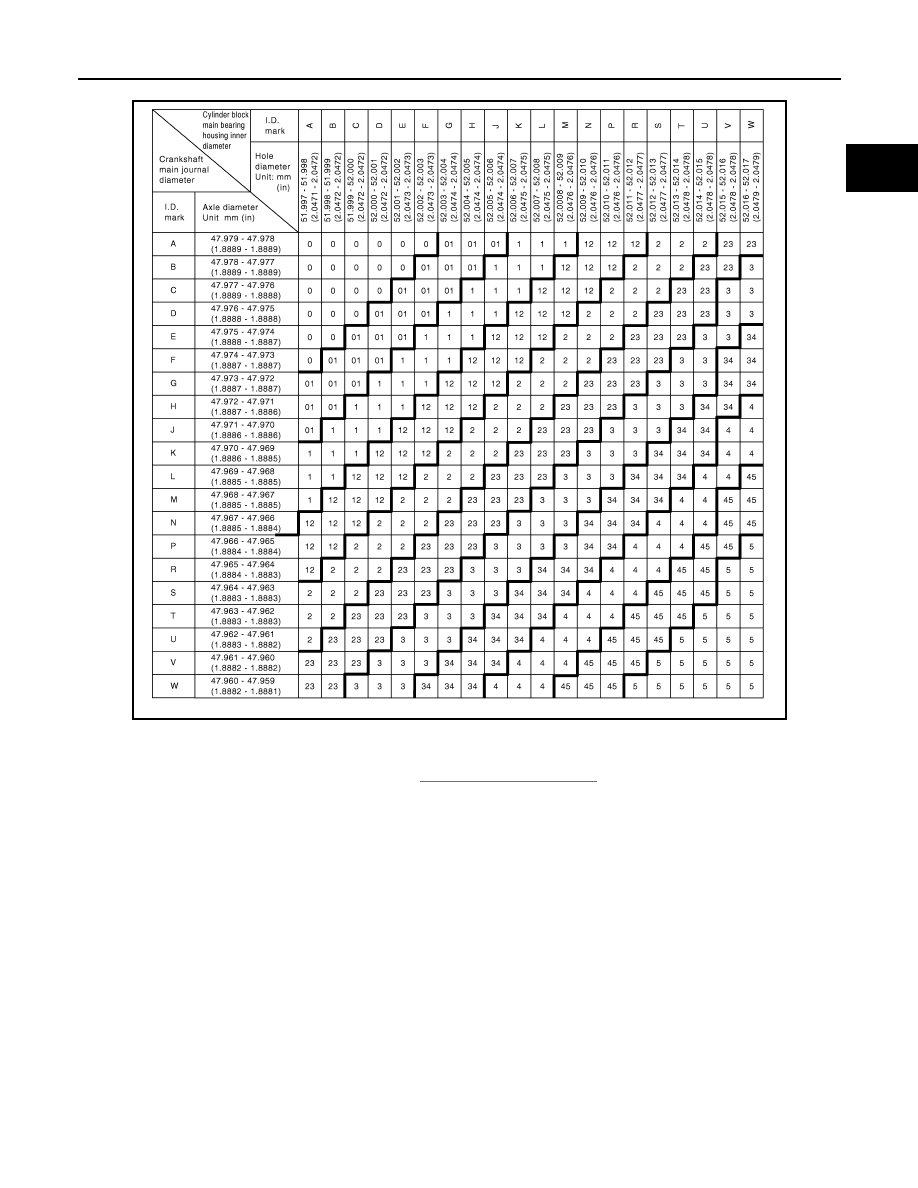

HOW TO SELECT PISTON AND BEARING

EM-113

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Main Bearing Selection Table

Main Bearing Grade Table

E1BIA1172GB

Main Bearing Grade Table

: Refer to