Qashqai J11. Engine control system (HRA2DDT) - part 2

COMPONENT PARTS

ECH-17

< SYSTEM DESCRIPTION >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

ECH

N

P

O

feedback to the ECM, when opens/closes the throttle valve in response to driving conditions via the throttle

control motor.

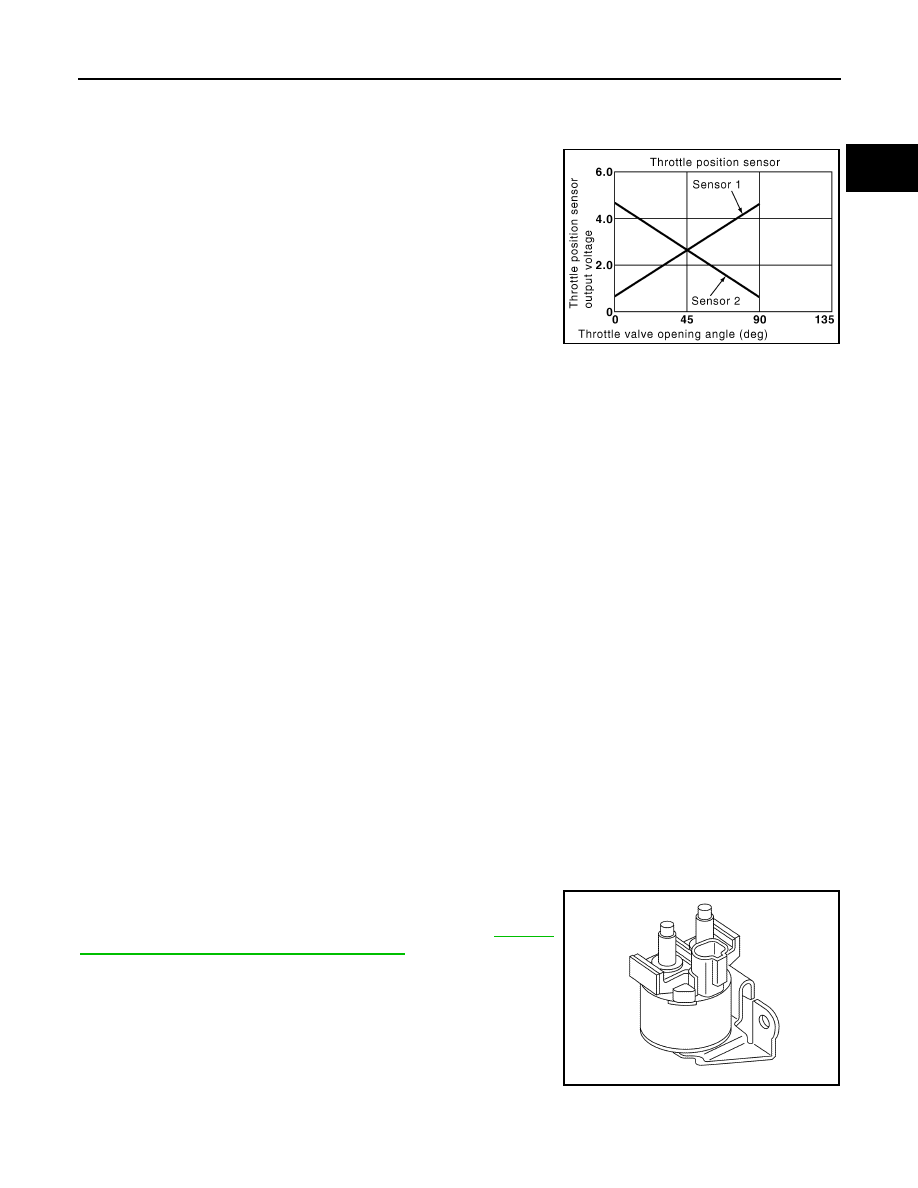

THROTTLE POSITION SENSOR

The throttle position sensor responds to the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometer which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. The ECM

judges the current opening angle of the throttle valve from these sig-

nals and controls the throttle valve opening angle in response to

driving conditions via the throttle control motor.

Engine Coolant Bypass Valve

INFOID:0000000010471168

Engine Coolant Bypass Valve switches the flow passage of engine coolant. This valve is controlled by Engine

Coolant Bypass Valve Control Solenoid Valve.

Engine Coolant Bypass Valve Control Solenoid Valve

INFOID:0000000010471169

Engine coolant bypass valve control solenoid valve is controlled by ECM. The solenoid valve controls negative

pressure given to diaphragm of engine coolant bypass valve. When engine coolant bypass valve control sole-

noid valve is activated, it opens solenoid valve and gives negative pressure from vacuum pump to diaphragm

of engine coolant bypass valve.

Engine Coolant Temperature Sensor

INFOID:0000000010379011

The engine coolant temperature sensor is used to detect the engine coolant temperature. The sensor modifies

a voltage signal from the ECM. The modified signal returns to the ECM as the engine coolant temperature

input.

Engine Oil Pressure Control Solenoid Valve

INFOID:0000000010471166

The engine oil pressure control solenoid valve regulates the engine oil pressure.

Engine Restart Relay

INFOID:0000000010471138

The engine restart relay is controlled by ECM when restarting the engine during the stop/start system opera-

tion.

Engine Restart Bypass Control Relay

INFOID:0000000010471139

The engine restart bypass control relay is controlled by ECM and controls the engine restart bypass relay.

Engine Restart Bypass Relay

INFOID:0000000010471140

The engine restart bypass relay reduces battery voltage drop right

after the starter motor activation at an engine restart by switching the

electric circuit of the starter motor. For details, refer to

"STOP/START SYSTEM : System Description"

.

PBIB0145E

JSBIA1994ZZ