Qashqai J11. Engine cooling system - part 2

RADIATOR

CO-17

< REMOVAL AND INSTALLATION >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

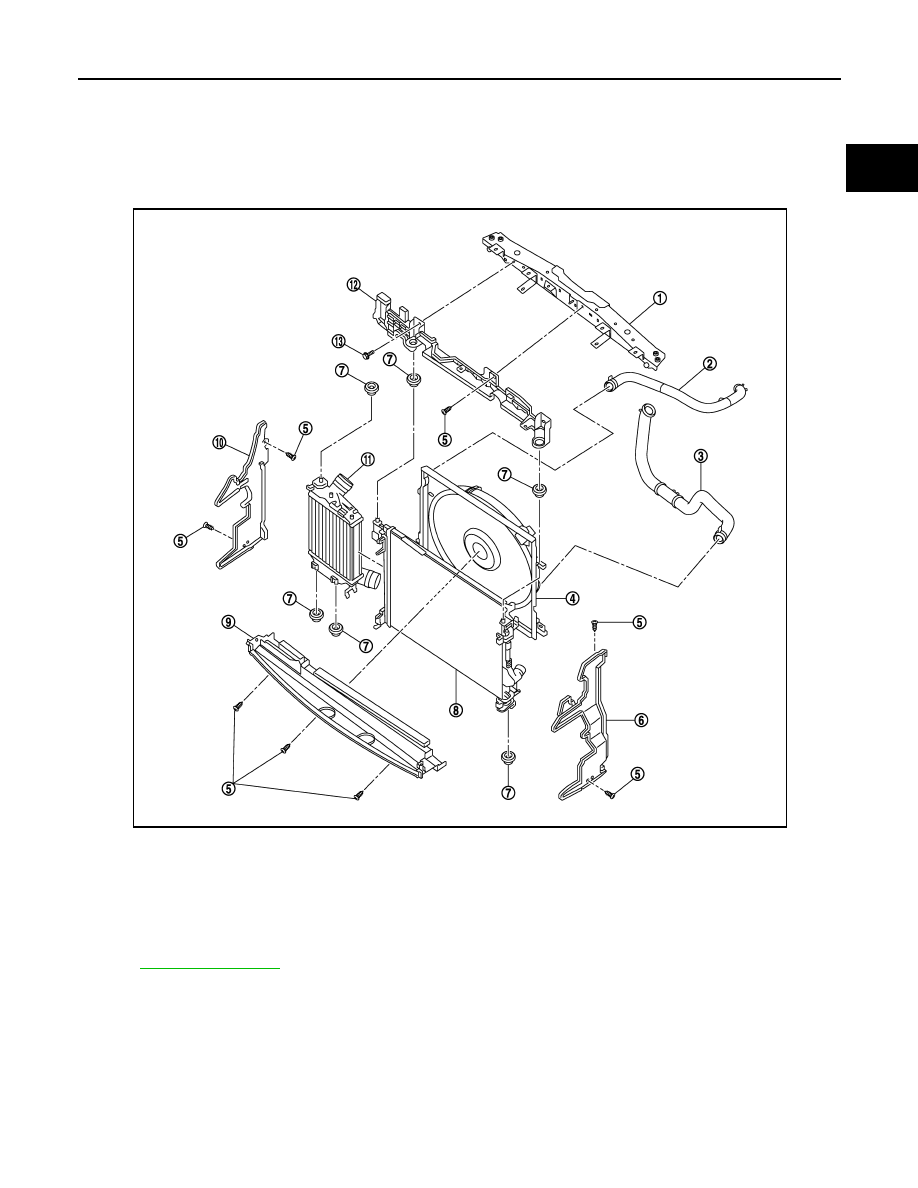

REMOVAL AND INSTALLATION

RADIATOR

Exploded View

INFOID:0000000010416347

for symbol marks in the figure.

Removal and Installation

INFOID:0000000010416348

REMOVAL

WARNING:

• Never remove reservoir tank cap when engine is hot. Serious burns may occur from high-pressure

engine coolant escaping from radiator.

• Wrap a thick cloth around the reservoir tank cap. Slowly turn it a quarter of a turn to release built-up

pressure. Then turn it all the way.

1.

Radiator core support

2.

Radiator hose (upper)

3.

Radiator hose (lower)

4.

Cooling fan assembly

5.

Clip

6.

Air guide (LH)

7.

Mounting rubber

8.

Radiator

9.

Air guide (Lower)

10. Air guide (RH)

11.

Intercooler

12. Radiator mounting bracket

13. Bolt

E1BIA1116GB