Nissan Qashqai J11. Manual - part 967

C1160 DECEL G SEN SET

BRC-105

< DTC/CIRCUIT DIAGNOSIS >

[WITH ESP]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1160 DECEL G SEN SET

DTC Logic

INFOID:0000000010329844

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

1.

Turn ignition switch OFF to ON.

2.

Perform self-diagnostic result.

Is DTC C1160 detected?

YES

>> Proceed to diagnosis procedure. Refer to

BRC-105, "Diagnosis Procedure"

NO

>> Inspection End.

Diagnosis Procedure

INFOID:0000000010329845

1.

DECEL G SENSOR CALIBRATION

Perform decel G sensor calibration. Refer to

>> GO TO 2.

2.

CHECK SELF-DIAGNOSTIC RESULT

With CONSULT.

Perform self-diagnostic result.

Is DTC C1160 detected?

YES

>> GO TO 3.

NO

>> Inspection End.

3.

CHECK YAW RATE/SIDE/DECEL G SENSOR SYSTEM

Check yaw rate/side/decel G sensor system. Refer to

Is the inspection result normal?

YES

>> Replace ABS actuator and electric unit (control unit). Refer to

BRC-142, "Removal and Installa-

.

NO

>> Repair or replace malfunctioning components.

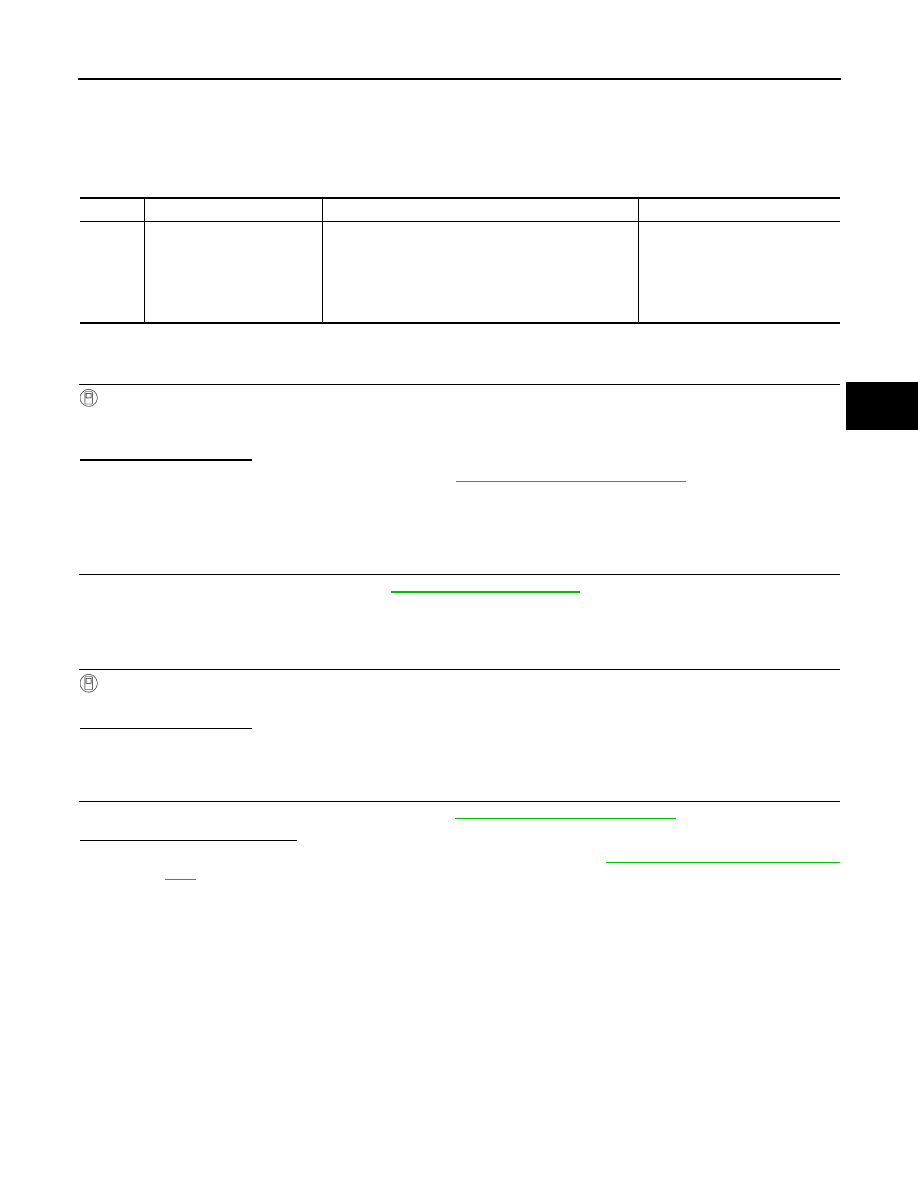

DTC

Display Item

Malfunction detected condition

Possible causes

C1160

DECEL G SEN SET

When calibration of yaw rate/side/decel G sensor is

not complete.

• Yaw rate/side/decel G sensor

• Harness or connector

• ABS actuator and electric unit

(control unit)

• Decel G sensor calibration is

not performed