Nissan Qashqai J11. Manual - part 754

P1890 ELECTRIC OIL PUMP RELAY

TM-591

< DTC/CIRCUIT DIAGNOSIS >

[CVT: RE0F10G]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

NO

>> GO TO 6.

3.

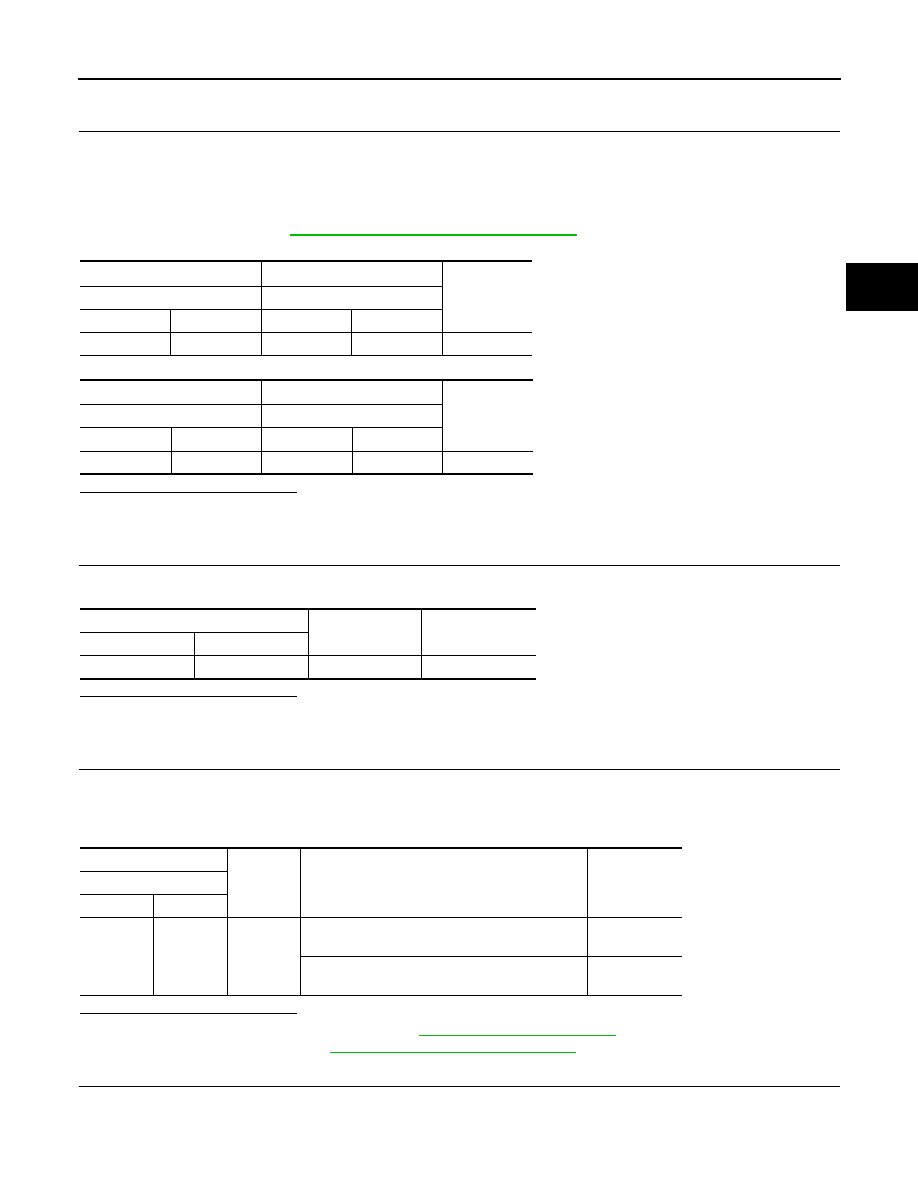

CHECK CIRCUIT BETWEEN TCM AND ELECTRIC OIL PUMP RELAY (PART 1)

1.

Disconnect the TCM connector.

2.

Check continuity between TCM harness connector terminal and electric oil pump relay harness connector

terminal.

NOTE:

• A diode is located between TCM and the electric oil pump relay.

• To check diode, refer to

TM-592, "Component Inspection (Diode)"

.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace malfunctioning parts.

4.

CHECK CIRCUIT BETWEEN TCM AND ELECTRIC OIL PUMP RELAY (PART 2)

Check continuity between the electric oil pump relay harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair or replace malfunctioning parts.

5.

CHECK ELECTRIC OIL PUMP RELAY SIGNAL

1.

Install the electric oil pump relay.

2.

Connect the TCM connector.

3.

Check the voltage between the TCM harness connector terminal and ground.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

TM-625, "Removal and Installation"

6.

DETECTION OF MALFUNCTION ITEMS

Check the following items:

• Fuse block (J/B)

+

−

Continuity

TCM

Electric oil pump relay

Connector

Terminal

Connector

Terminal

F1

1

F119

2

Existed

+

−

Continuity

Electric oil pump relay

TCM

Connector

Terminal

Connector

Terminal

F119

2

F1

1

Not existed

Electric oil pump relay

—

Continuity

Connector

Terminal

F119

2

Ground

Not existed

+

−

Condition

Voltage

TCM

Connector

Terminal

F1

1

Ground

• Selector lever: “D”position

• Vehicle speed: 11 km/h (7 MPH) or more

10 – 16 V

• Selector lever: “D”position

• Vehicle speed: 6 km/h (3 MPH) or less

Approx. 0 V