Nissan Qashqai J11. Manual - part 721

SYSTEM

TM-459

< SYSTEM DESCRIPTION >

[CVT: RE0F10G]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

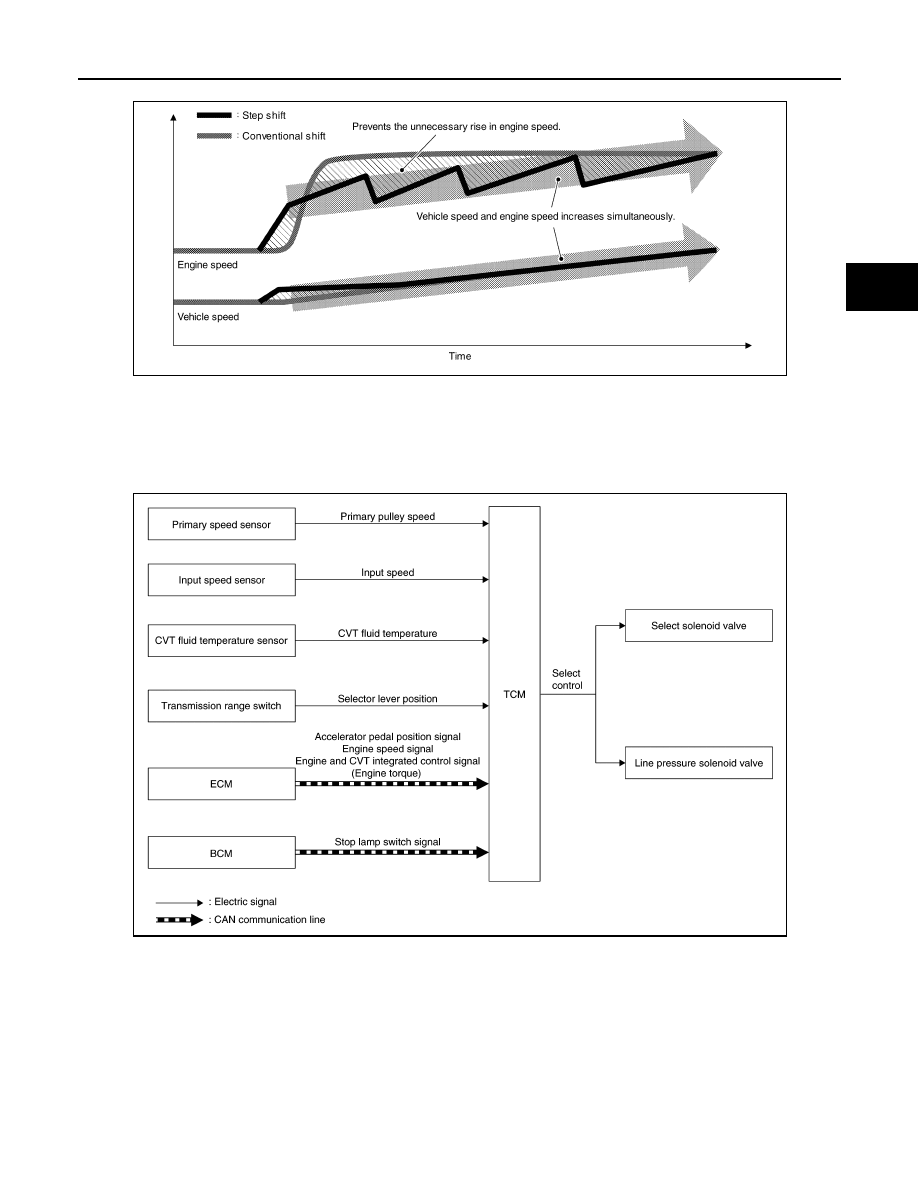

SELECT CONTROL

SELECT CONTROL : System Description

INFOID:0000000010245551

SYSTEM DIAGRAM

DESCRIPTION

Based on accelerator pedal angle, engine speed, primary pulley speed, and the input speed, the optimum

operating pressure is set to reduce impact of a selector lever operation while shifting from “N” (“P”) to “D” (“R”)

position.

LOCK-UP CONTROL

LOCK-UP CONTROL : System Description

INFOID:0000000010245552

SYSTEM DIAGRAM

JSDIA5273GB

JSDIA3711GB