Nissan Qashqai J11. Manual - part 142

LU-28

< REMOVAL AND INSTALLATION >

[MR20DD]

OIL COOLER

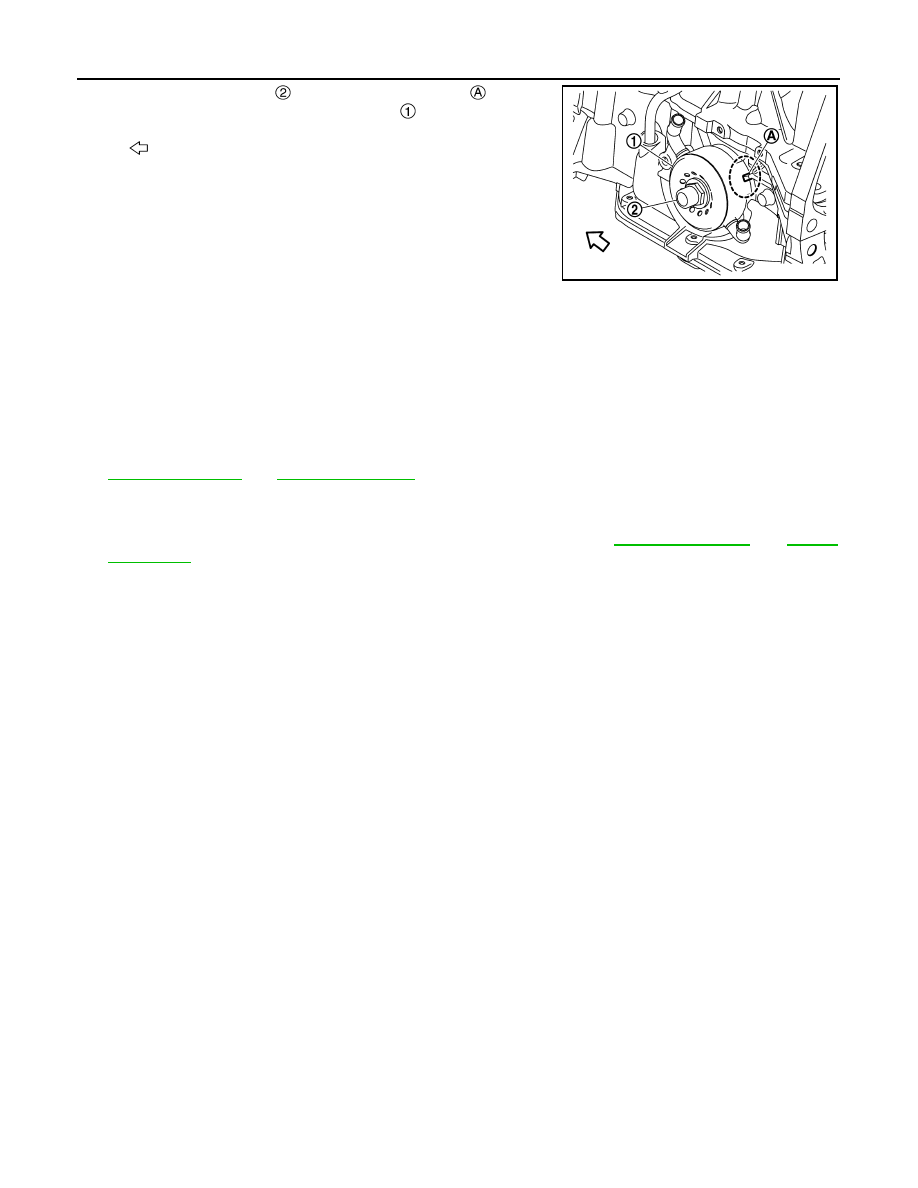

• Tighten the connector bolt

after aligning the stopper

on the oil

pan (upper) side with protrusion of oil cooler

.

Inspection

INFOID:0000000010624161

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to

and

2.

Start the engine, and check that there is no leakage of engine oil or engine coolant.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level and the engine coolant level again. Refer to

: Engine front

JPBIA6907ZZ