Content .. 1172 1173 1174 1175 ..

Nissan Qashqai J11. Manual - part 1174

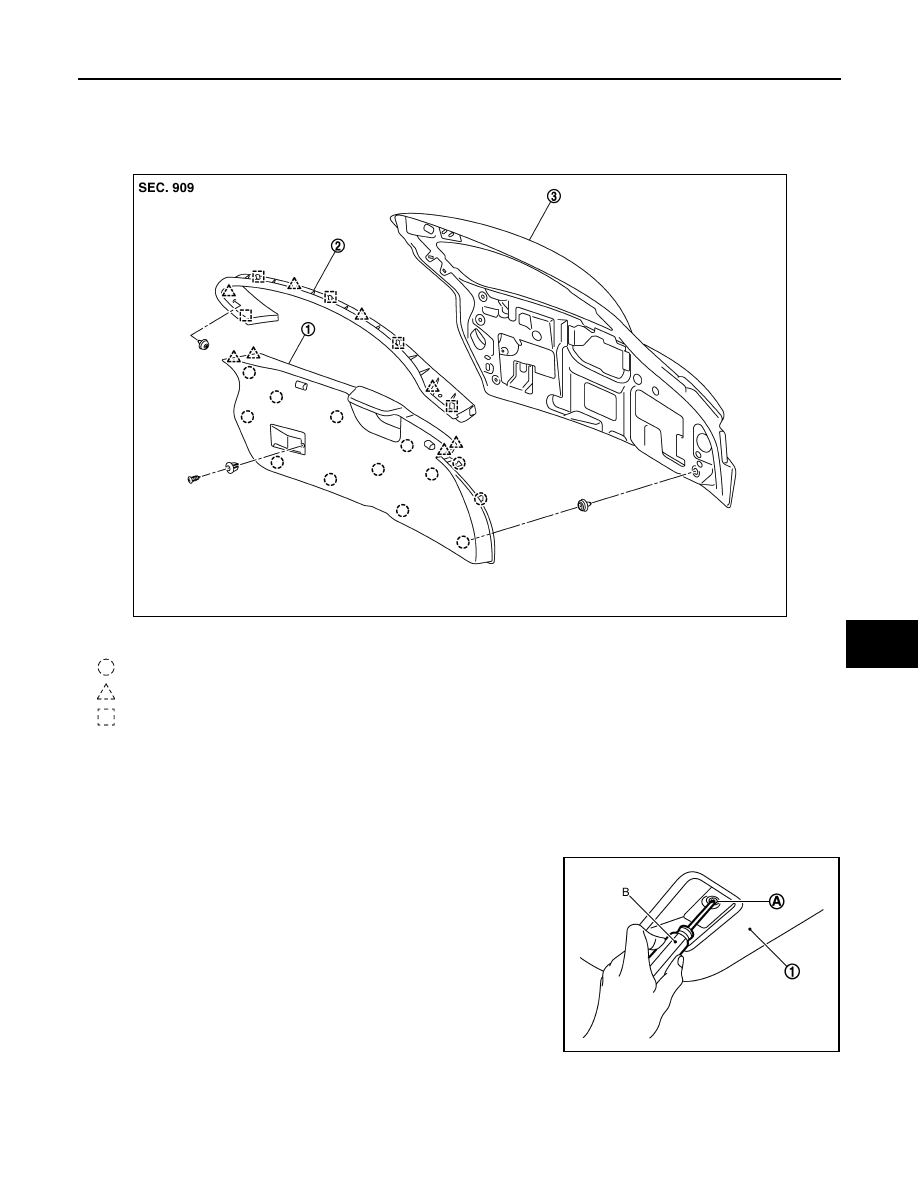

BACK DOOR TRIM

INT-31

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

K

L

M

A

B

INT

N

O

P

BACK DOOR TRIM

Exploded View

INFOID:0000000010350955

Removal and Installation

INFOID:0000000010350956

REMOVAL

BACK DOOR TRIM

1.

Fully open back door.

2.

Remove screw tap (A) located in back door trim finisher lower

(1) with screwdriver (B).

1.

Back door trim finisher lower

2.

Back door trim finisher upper

3.

Back door assembly

: Clip

: Pawl

: Metal clip

JMJIA0231ZZ

JMJIA0233ZZ