Content .. 1117 1118 1119 1120 ..

Nissan Qashqai J11. Manual - part 1119

HAC-112

< DTC/CIRCUIT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONING]

BLOWER MOTOR

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 9.

9.

CHECK POWER TRANSISTOR CONTROL SIGNAL CIRCUIT FOR OPEN

1.

Turn ignition switch OFF.

2.

Disconnect power transistor connector and A/C auto amp. connector.

3.

Check continuity between power transistor harness connector and A/C auto amp. harness connector.

Is the inspection result normal?

YES

>> Replace A/C auto amp. Refer to

HAC-129, "Removal and Installation"

.

NO

>> Repair harness or connector.

10.

CHECK BLOWER MOTOR FEEDBACK SIGNAL

When fan speed is set to OFF, and check voltage between power transistor harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> GO TO 11.

11.

CHECK BLOWER MOTOR FEEDBACK SIGNAL CIRCUIT FOR OPEN

1.

Turn ignition switch OFF.

2.

Disconnect power transistor connector and A/C auto amp. connector.

3.

Check continuity between power transistor harness connector and A/C auto amp. harness connector.

Is the inspection result normal?

YES

>> Replace A/C auto amp. Refer to

HAC-129, "Removal and Installation"

.

NO

>> Repair harness or connector.

12.

REPLACE POWER TRANSISTOR

1.

Turn ignition switch OFF.

2.

Replace power transistor. Refer to

HAC-136, "Removal and Installation"

3.

Turn ignition switch ON.

4.

Change fan speed from 1st – 7th, and check that blower motor operates normally.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace blower motor. Refer to

VTL-17, "Removal and Installation"

.

Component Inspection (Blower Motor)

INFOID:0000000010432236

1.

CHECK BLOWER MOTOR-I

1.

Remove blower motor. Refer to

VTL-17, "Removal and Installation"

2.

Check that there is not any mixing foreign object in the blower motor.

Is the inspection result normal?

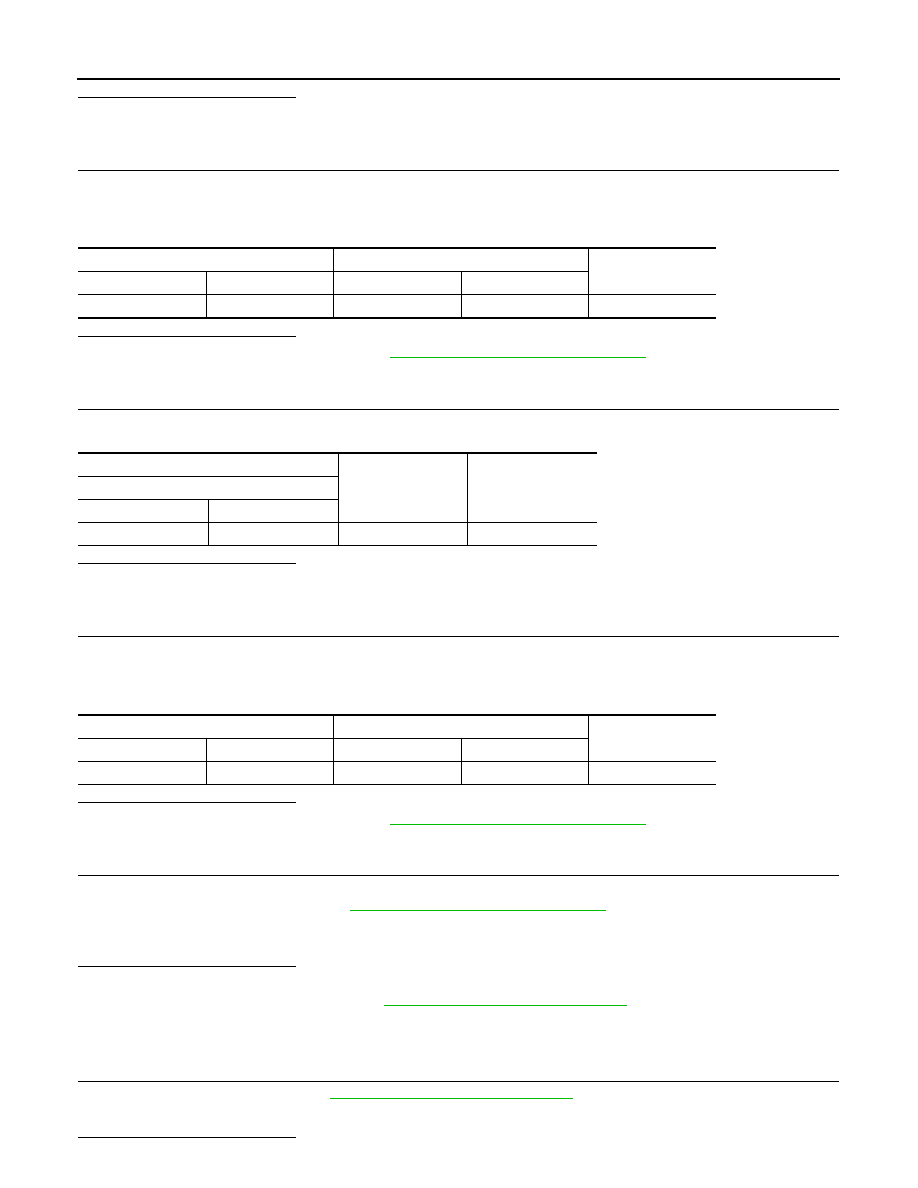

Power transistor

A/C auto amp.

Continuity

Connector

Terminal

Connector

Terminal

M359

3

M140

27

Existed

+

−

Voltage

Power transistor

Connector

Terminal

M359

1

Ground

Battery voltage

Power transistor

A/C auto amp.

Continuity

Connector

Terminal

Connector

Terminal

M359

1

M140

37

Existed