Content .. 1085 1086 1087 1088 ..

Nissan Qashqai J11. Manual - part 1087

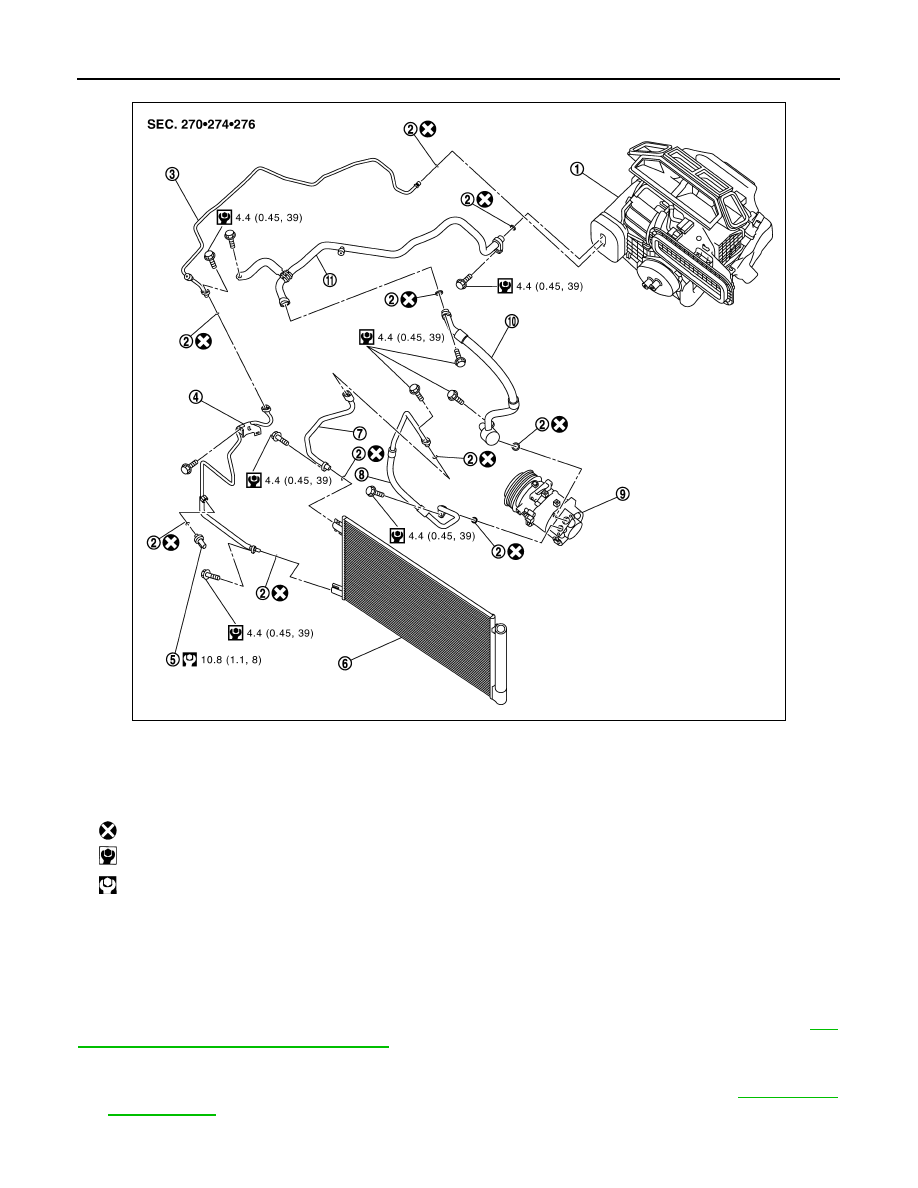

HA-174

< REMOVAL AND INSTALLATION >

[TYPE 4]

COOLER PIPE AND HOSE

R9M engine models

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and Installation

INFOID:0000000010707894

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly. However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return operation. Refer to

67, "Perform Lubricant Return Operation"

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to

2.

Remove mounting bolt, and then disconnect high-pressure flexible hose from the high-pressure pipe 2.

JMIIA3632GB

1.

A/C unit assembly

2.

O-ring

3.

High-pressure pipe 3

4.

High-pressure pipe 1

5.

Refrigerant pressure sensor

6.

Condenser & liquid tank assembly

7.

High-pressure pipe 2

8.

High-pressure flexible hose

9.

Compressor

10. Low-pressure flexible hose

11.

Low-pressure pipe

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)