Nissan Qashqai J11. Manual - part 99

CYLINDER BLOCK

EM-335

< UNIT DISASSEMBLY AND ASSEMBLY >

[K9K]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

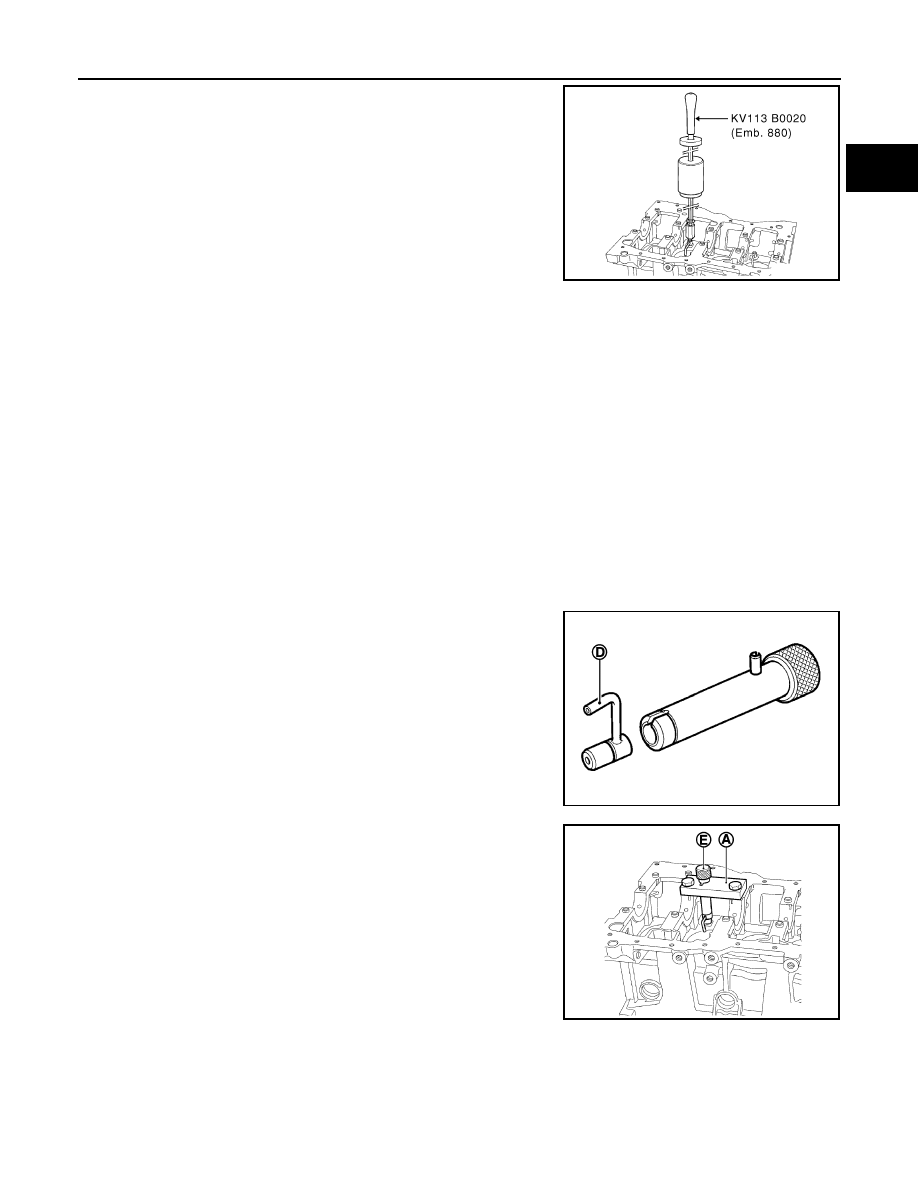

19. Screw sliding hammer [SST: KV113B0020 (Emb. 880)] onto oil

jet remover [SST: KV113B0120 (Mot. 1485-01)] and remove the

oil jet.

20. To remove the piston pin, remove the snap ring using a screwdriver, then release the pin.

Removing the Piston Pins

NOTE:

It is imperative to mark the connecting rod to match it to its piston, because the piston height classes

in the same engine may be different (see Technical Specifications section).

ASSEMBLY

1.

The oil jets must be installed using oil jet remover plate [SST: KV113B0170 (Mot. 1494)].

2.

Install oil jets for NO. 1 and NO. 3 cylinders with the following procedure.

a.

Install plate (A) of oil jet remover plate [SST: KV113B0170 (Mot. 1494)] onto the cylinder block (as shown

in the figure) without tightening the two bolts (C).

b.

Position the guide rod (B) in the plate (A) and the end of the guide rod in the hole of the oil jet to center the

plate (A).

c.

Tighten the two bolts (C).

d.

Remove the guide rod.

e.

Install the push rod instead of the guide rod, then insert the oil jet

into the push rod.

NOTE:

Check that the oil jet is correctly oriented with the end of

the jet (D) directed towards the center of the cylinder.

f.

With a hammer, tap the push rod until the shoulder (E) of the

push rod comes into contact with the plate (A).

3.

Install oil jets for NO. 1 and NO.4 cylinders with the following procedure.

MBIB0451E

MBIB0453E

MBIB0454E