Nissan Qashqai J11. Manual - part 71

CYLINDER BLOCK

EM-223

< UNIT DISASSEMBLY AND ASSEMBLY >

[MR20DD]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Disassembly and Assembly

INFOID:0000000010715516

DISASSEMBLY

1.

Remove oil pan (upper). Refer to

.

2.

Remove thermostat housing. Refer to

3.

Remove knock sensor.

CAUTION:

Handle it carefully and avoid impacts.

4.

Remove crankshaft position sensor (POS) cover and crankshaft position sensor (POS).

CAUTION:

• Handle crankshaft position sensor (POS) carefully and avoid impacts.

• Never disassemble.

• Never place crankshaft position sensor (POS) in a location where it is exposed to magnetism.

5.

Remove oil filter (for intake valve timing control).

6.

Remove piston and connecting rod assembly with the following procedure:

• Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer to

.

a.

Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

b.

Remove connecting rod cap.

c.

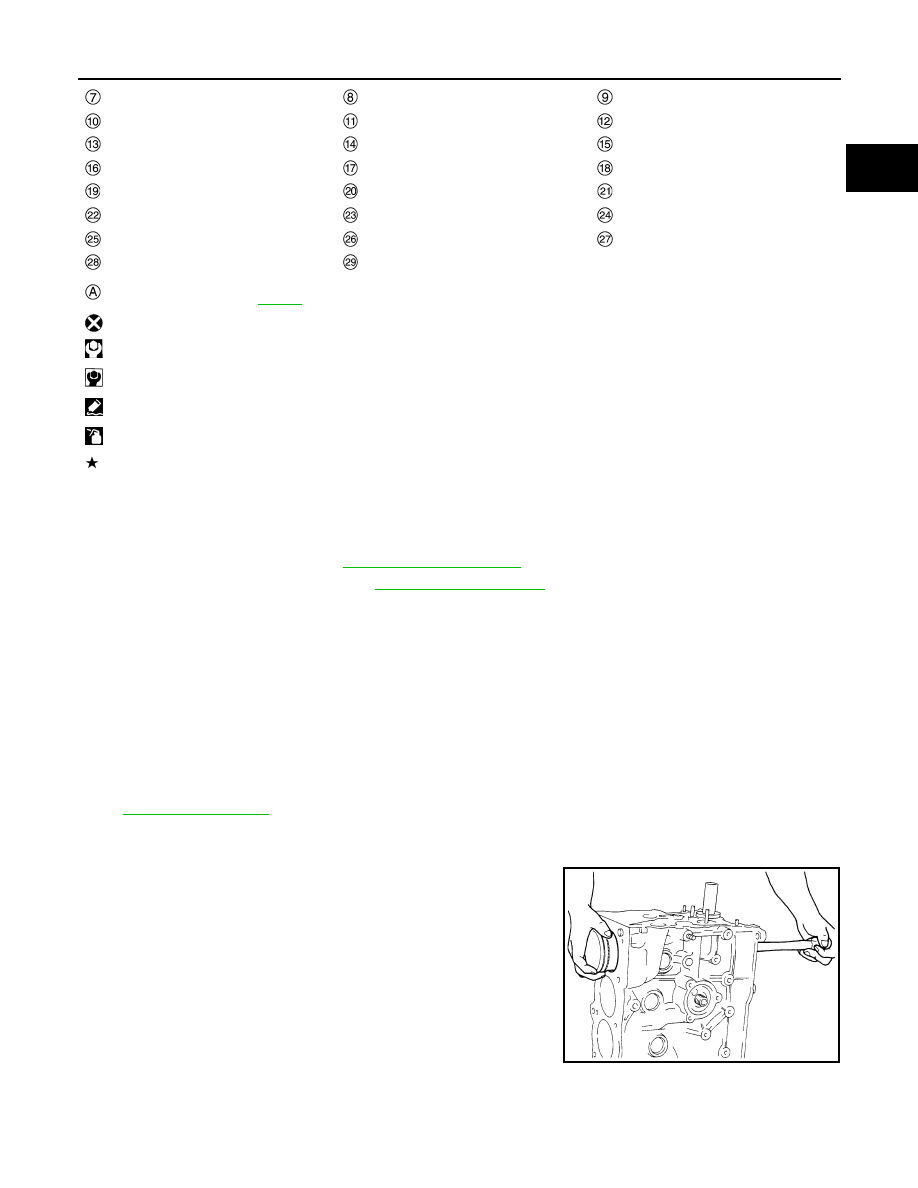

Using a hammer handle or similar tool, push piston and connect-

ing rod assembly out to the cylinder head side.

CAUTION:

• Be careful not to damage matching surface with connect-

ing rod cap.

• Be careful not to damage the cylinder wall and crankshaft

pin, resulting from an interference of the connecting rod

big end.

7.

Remove connecting rod bearings.

CAUTION:

When removing them, note the installation position. Keep them in the correct.

Oil pressure switch

Oil tempareture sensor

Oil jet

Top ring

Second ring

Oil ring

Snap ring

Piston

Piston pin

Connecting rod

Thrust bearing

Connecting rod bearing (upper)

Main bearing (upper)

Crankshaft key

Main bearing (lower)

Connecting rod bearing (lower)

Connecting rod cap

Connecting rod cap bolt

Main bearing cap

Main bearing cap bolt

Crankshaft

Signal plate

Rear oil seal

Comply with the installation procedure

when tightening. Refer to

: Always replace after every disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Sealing point

: Should be lubricated with oil.

: Select with proper thickness.

PBIC0259E