Nissan Qashqai J11. Manual - part 32

TIMING CHAIN

EM-67

< UNIT DISASSEMBLY AND ASSEMBLY >

[HRA2DDT]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

e.

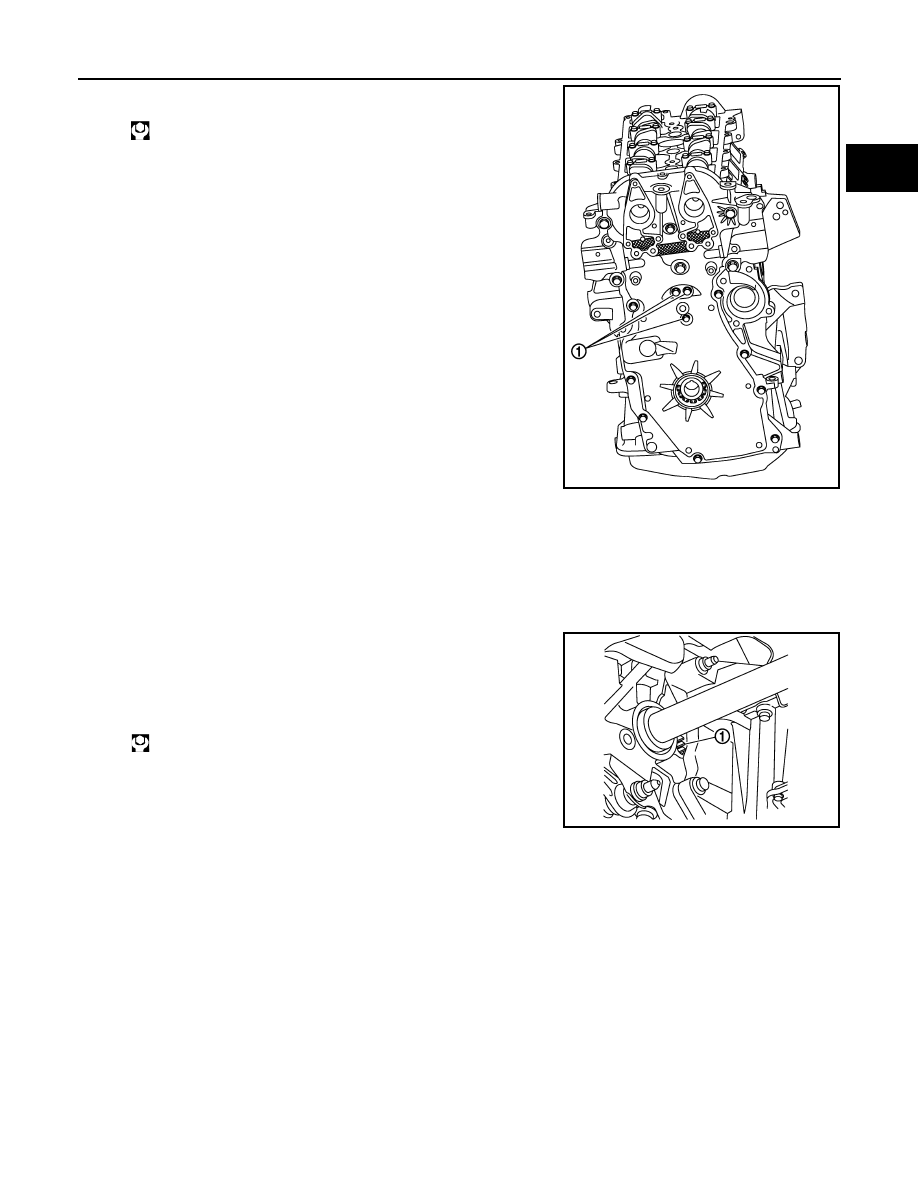

After all bolts are tightened, instal front cover bolts (1).

9.

Insert crankshaft pulley by aligning with crankshaft key.

• When inserting crankshaft pulley with a plastic hammer, tap on its center portion (not circumference).

CAUTION:

Install protecting front oil seal lip section from any damage.

10. Tighten crankshaft pulley bolt with the following procedure:

• Lock the flywheel (1) using a flat blade screw driver.

a.

Apply new engine oil to thread and seat surfaces of crankshaft

pulley bolt.

b.

Tighten crankshaft pulley bolt.

c.

Turn another 200 degrees clockwise (angle tightening).

• Check the tightening angle with movement of one angle mark.

11. Check that crankshaft turns smoothly by rotating by hand clockwise.

12. Install in the reverse order of removal.

Inspection

INFOID:0000000010351306

INSPECTION AFTER REMOVAL

Timing Chain

: 10.0 N·m (1.0 kg-m, 7 ft-lb)

E1BIA1089ZZ

: 50.0 N·m (5.1 kg-m, 37 ft-lb)

E1BIA1090ZZ