Nissan Juke F15. Manual - part 946

LAN

CAN COMMUNICATION CIRCUIT

LAN-121

< DTC/CIRCUIT DIAGNOSIS >

[CAN SYSTEM (TYPE 4)]

C

D

E

F

G

H

I

J

K

L

B

A

O

P

N

CAN COMMUNICATION CIRCUIT

Diagnosis Procedure

INFOID:0000000012200591

1.

CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4. Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair the terminal and connector.

2.

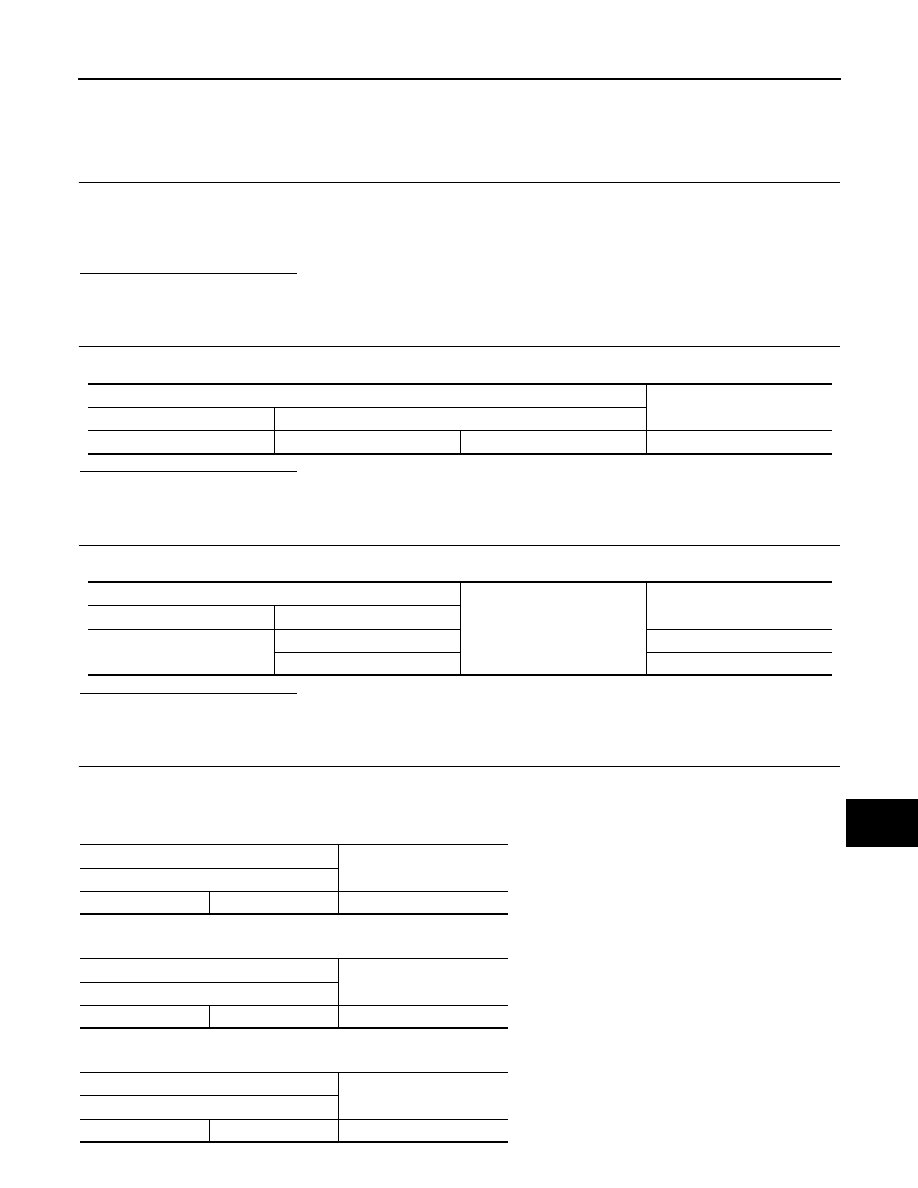

CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Check the harness and repair the root cause.

3.

CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Check the harness and repair the root cause.

4.

CHECK ECM AND BCM TERMINATION CIRCUIT

1. Remove the ECM and the BCM.

2. Check the resistance between the ECM terminals.

-

For NISMO RS models

-

Except for NISMO RS models

3. Check the resistance between the BCM terminals.

Data link connector

Continuity

Connector No.

Terminal No.

M4

6

14

Not existed

Data link connector

Ground

Continuity

Connector No.

Terminal No.

M4

6

Not existed

14

Not existed

ECM

Resistance (

Ω)

Terminal No.

100

99

Approx. 108 – 132

ECM

Resistance (

Ω)

Terminal No.

124

123

Approx. 108 – 132

BCM

Resistance (

Ω)

Terminal No.

39

40

Approx. 108 – 132