Nissan Juke F15. Manual - part 833

DIAGNOSIS AND REPAIR WORKFLOW

HA-15

< BASIC INSPECTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

BASIC INSPECTION

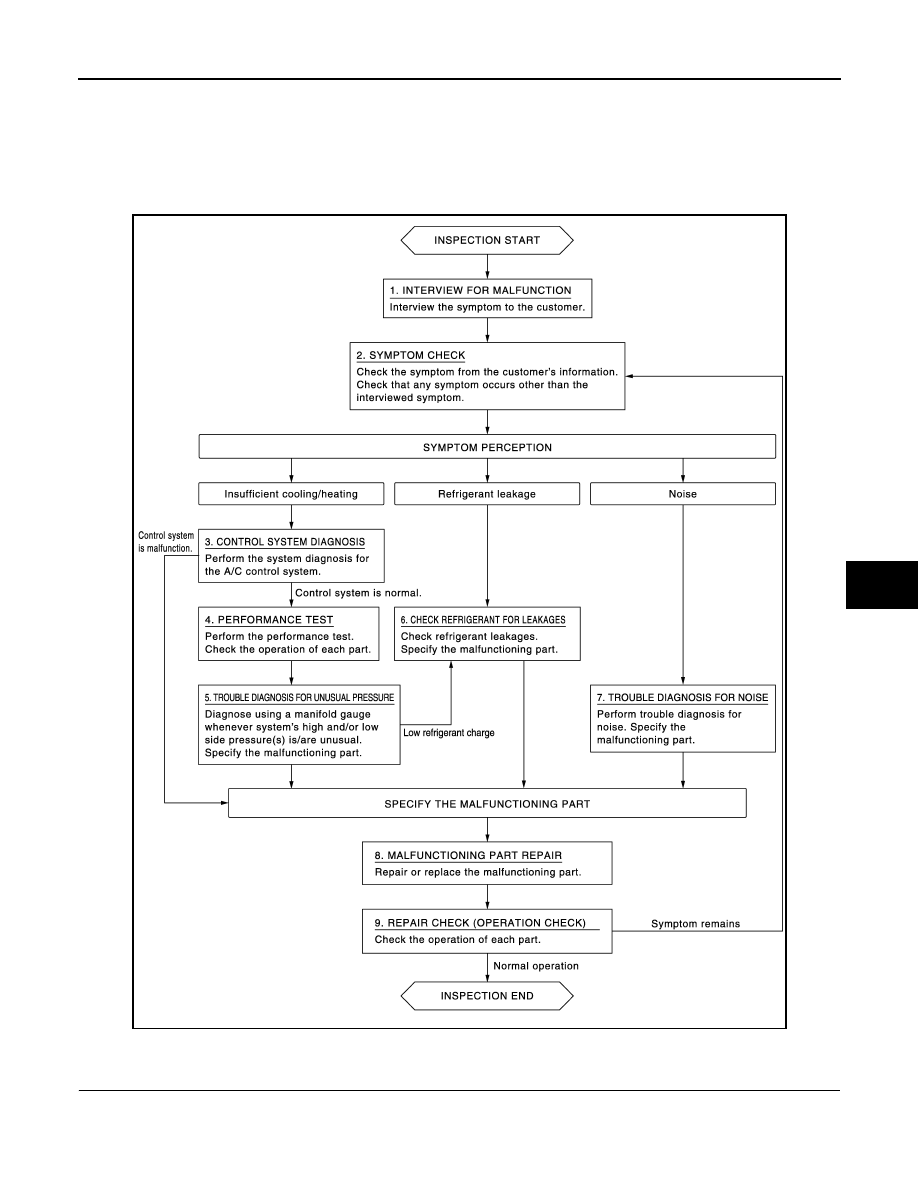

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000012197108

OVERALL SEQUENCE

DETAILED FLOW

1.

INTERVIEW FOR MALFUNCTION

Interview the symptom to the customer.

NNIIA0143GB