Nissan Juke F15. Manual - part 813

TIGHTENING TORQUE OF STANDARD BOLTS

GI-21

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

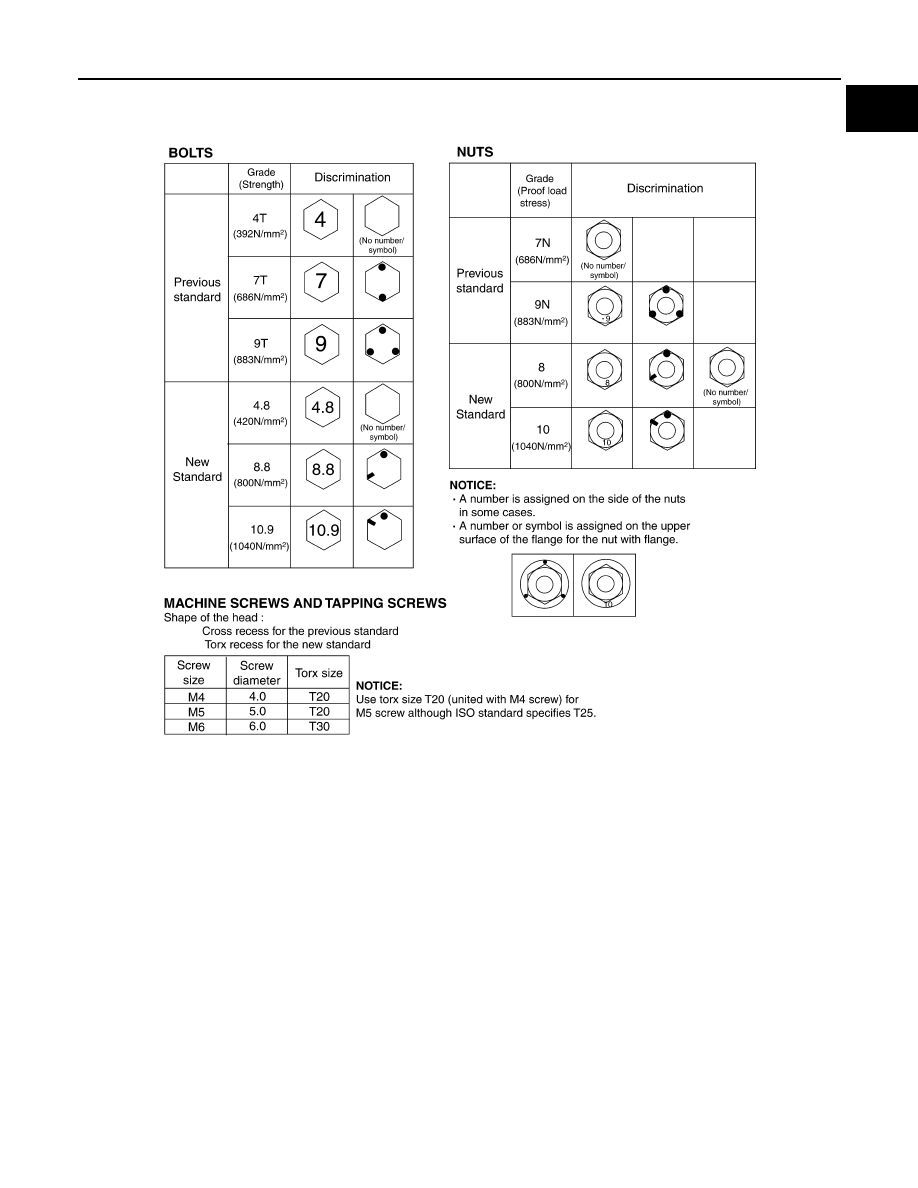

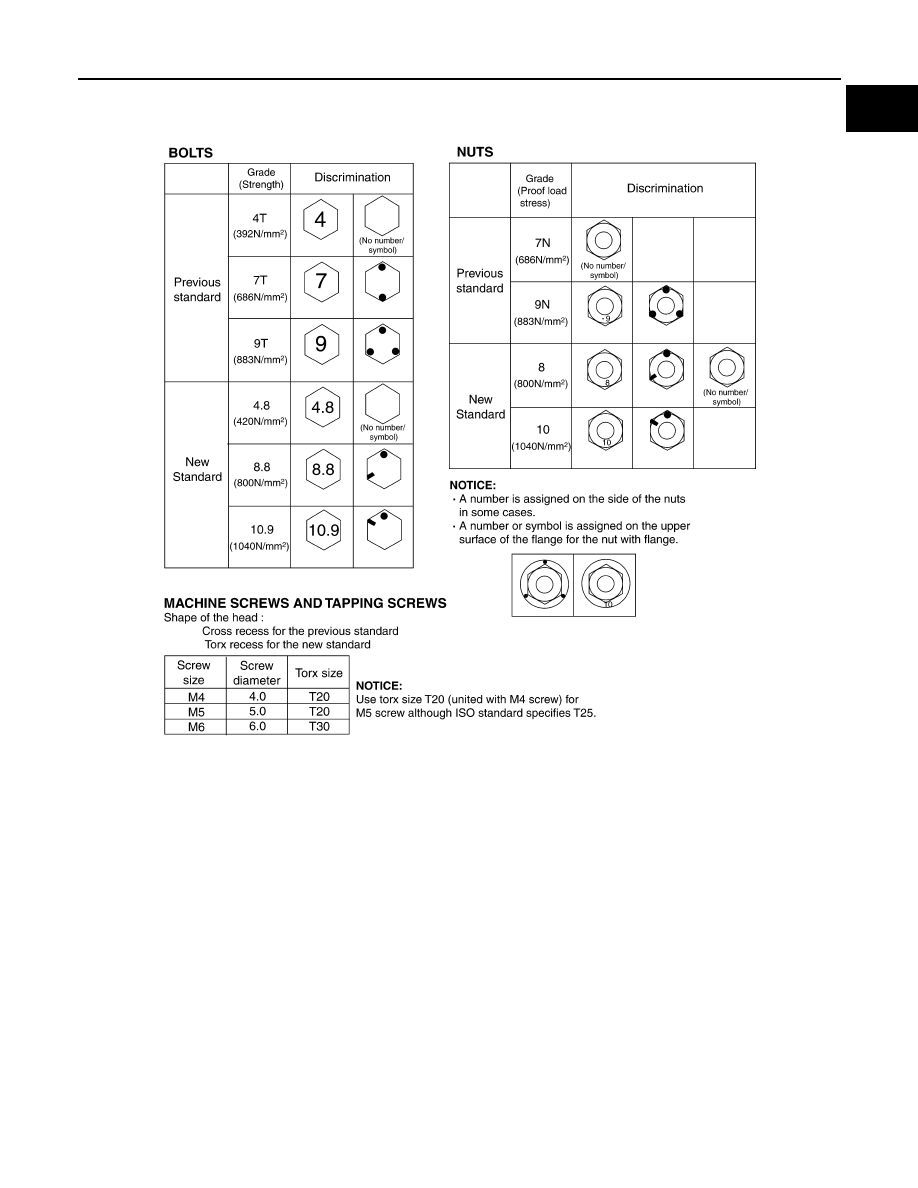

DISCRIMINATION OF BOLTS AND NUTS

SAIA0453E

|

|

|

TIGHTENING TORQUE OF STANDARD BOLTS GI-21 < HOW TO USE THIS MANUAL > C D E F G H I J K L M B GI N O P DISCRIMINATION OF BOLTS AND NUTS SAIA0453E |