Nissan Juke F15. Manual - part 736

EXL-164

< DTC/CIRCUIT DIAGNOSIS >

[HALOGEN TYPE]

HEADLAMP (HI) CIRCUIT

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace harness.

9.

CHECK DAYTIME RUNNING LIGHT RELAY

Check daytime running light relay. Refer to

EXL-164, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> Replace daytime running light relay.

10.

CHECK HEADLAMP (HI) RH BULB

Check the headlamp (HI) RH bulb.

Is the inspection result normal?

YES

>> Check the headlamp (HI) RH harness. Repair or replace if necessary.

NO

>> Replace headlamp (HI) RH bulb. Refer to

.

11.

CHECK HEADLAMP (HI) LH GROUND CIRCUIT

Check continuity between headlamp harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Repair or replace harness.

12.

CHECK HEADLAMP (HI) LH BULB

Check the headlamp (HI) LH bulb.

Is the inspection result normal?

YES

>> Check the headlamp (HI) LH harness. Repair or replace if necessary.

NO

>> Replace headlamp (HI) LH bulb. Refer to

Component Inspection

INFOID:0000000012201743

1.

CHECK DAYTIME RUNNING LIGHT RELAY

1. Turn ignition switch OFF.

2. Remove daytime running light relay.

3. Apply battery voltage to daytime running light relay between terminals 2 and 1.

4. Check continuity of daytime running light relay terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace daytime running light relay.

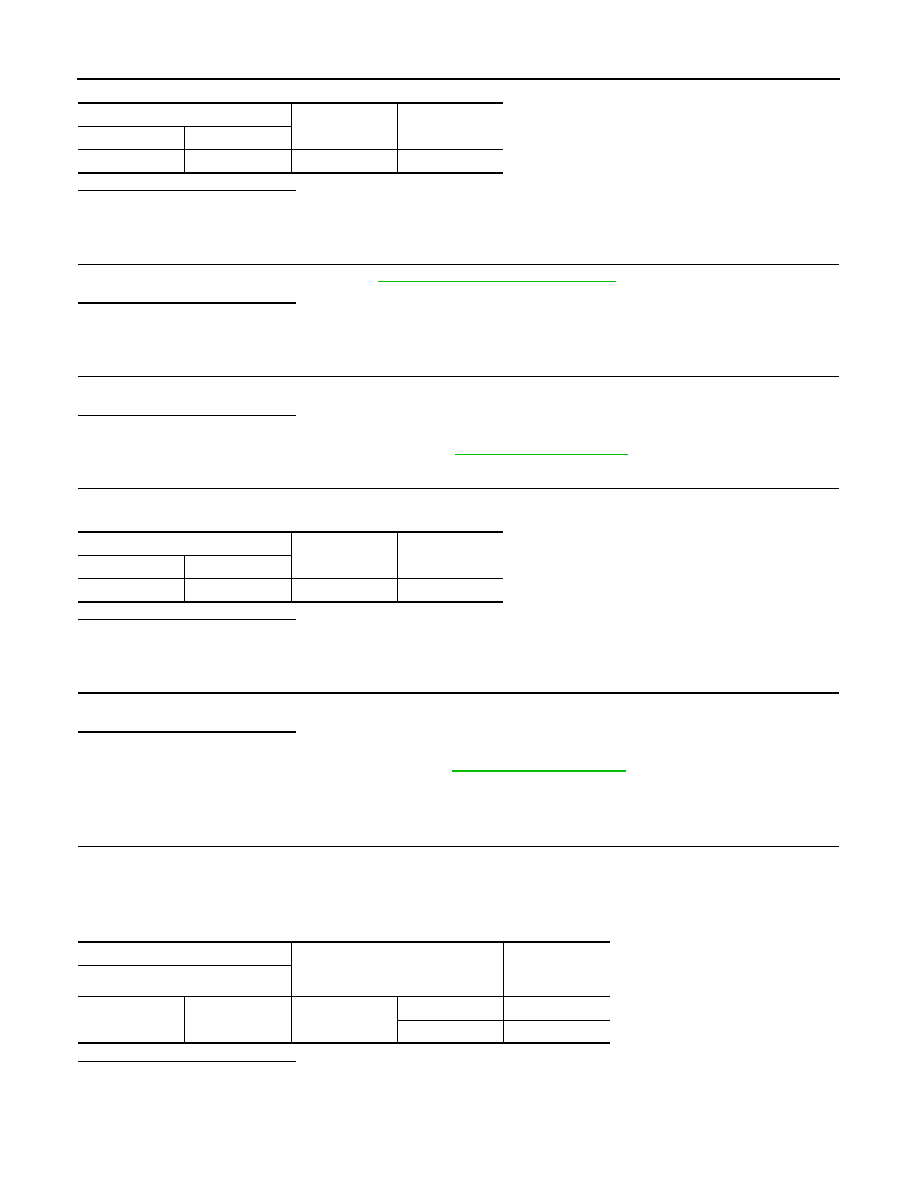

Daytime running light relay

—

Continuity

Connector

Terminal

E65

4

Ground

Existed

Headlamp

—

Continuity

Connector

Terminal

E54

3

Ground

Existed

Daytime running light relay

Condition

Continuity

Terminal

3

4

Battery voltage

Apply

Not existed

Not apply

Existed