Nissan Juke F15. Manual - part 602

HO2S2 HEATER

EC-1221

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

HO2S2 HEATER

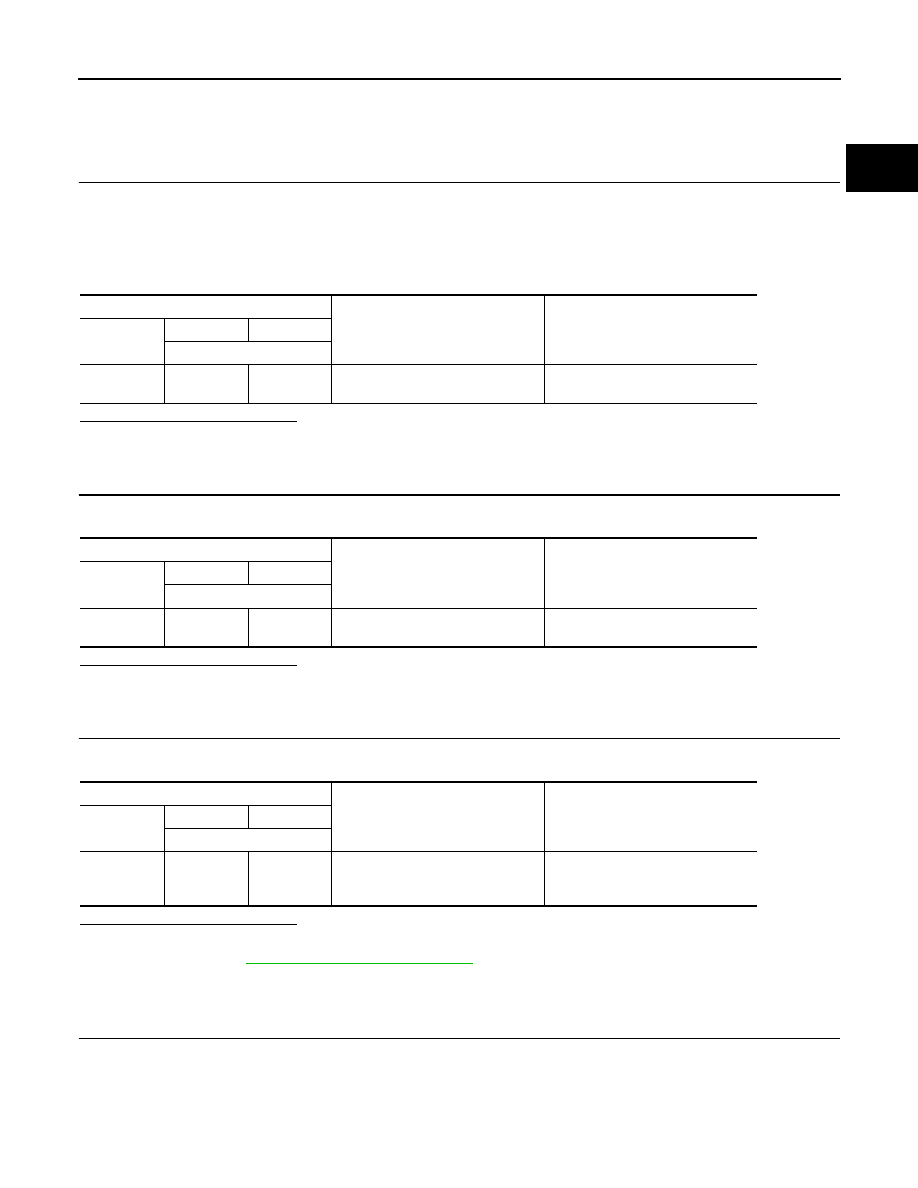

Component Function Check

INFOID:0000000012198750

1.

PERFORM COMPONENT FUNCTION CHECK-I

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

PERFORM COMPONENT FUNCTION CHECK-II

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 3.

3.

PERFORM COMPONENT FUNCTION CHECK-III

Check the voltage between ECM harness connector and ground as per the following condition.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Proceed to

EC-1221, "Diagnosis Procedure"

.

Diagnosis Procedure

INFOID:0000000012198751

1.

CHECK HO2S2 POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

3. Turn ignition switch ON.

4. Check the voltage between HO2S2 harness connector and ground.

ECM

Condition

Voltage

Connector

+

−

Terminal

F71

84

78

Revving up to 4,000 rpm under no

load at least 10 times

The voltage should be above 0.68 V

at least once during this procedure.

ECM

Condition

Voltage

Connector

+

−

Terminal

F71

84

78

Keeping engine speed at idle for 10

minutes

The voltage should be above 0.68 V

at least once during this procedure.

ECM

Condition

Voltage

Connector

+

−

Terminal

F71

84

78

Coasting from 80 km/h (50 MPH) in

D position (CVT), 4th gear position

(M/T)

The voltage should be above 0.68 V

at least once during this procedure.