Nissan Juke F15. Manual - part 499

P0037, P0038 HO2S2 HEATER

EC-809

< DTC/CIRCUIT DIAGNOSIS >

[MR EXCEPT FOR NISMO RS MODELS]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace error-detected parts.

2.

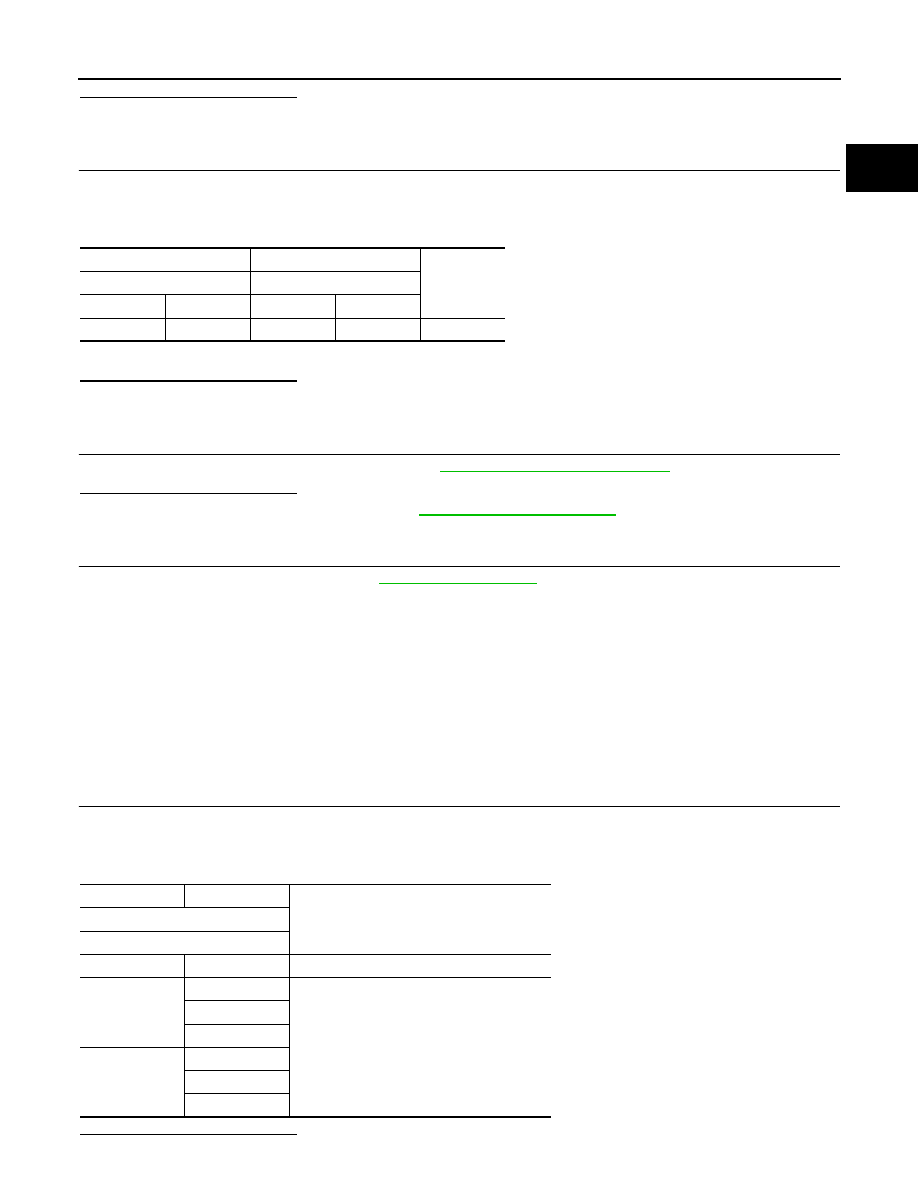

CHECK HO2S2 HEATER OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between HO2S2 harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace error-detected parts.

3.

CHECK HEATED OXYGEN SENSOR 2 HEATER

Check the heated oxygen sensor 2 heater. Refer to

EC-809, "Component Inspection"

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-45, "Intermittent Incident"

.

NO

>> GO TO 4.

4.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to

.

CAUTION:

• Discard any sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a hard

surface such as a concrete floor; use a new one.

• Before installing new sensor, clean exhaust system threads using Oxygen Sensor Thread Cleaner

[commercial service tool (J-43897-18 or J43897-12)] and approved Anti-seize Lubricant (commercial

service tool).

>> INSPECTION END

Component Inspection

INFOID:0000000012198312

1.

CHECK HEATED OXYGEN SENSOR 2 HEATER

1. Turn ignition switch OFF.

2. Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

3. Check resistance between HO2S2 terminals as per the following.

Is the inspection result normal?

+

−

Continuity

HO2S2

ECM

Connector

Terminal

Connector

Terminal

F71

3

F24

117

Existed

+

−

Resistance

Heated oxygen sensor 2

Terminal

4

3

3.3 - 4.4

Ω [at 25°C (77°F)]

1

2

∞ Ω

(Continuity should not exist)

3

4

2

1

3

4